continued from above

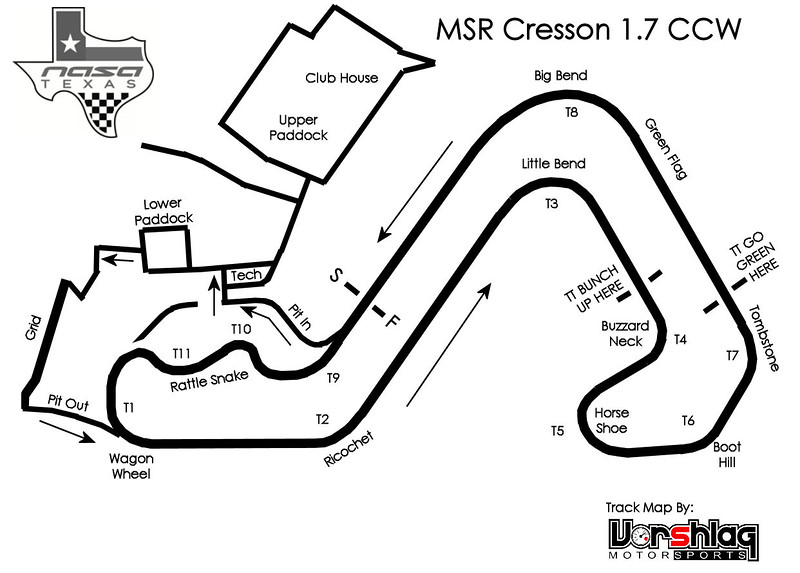

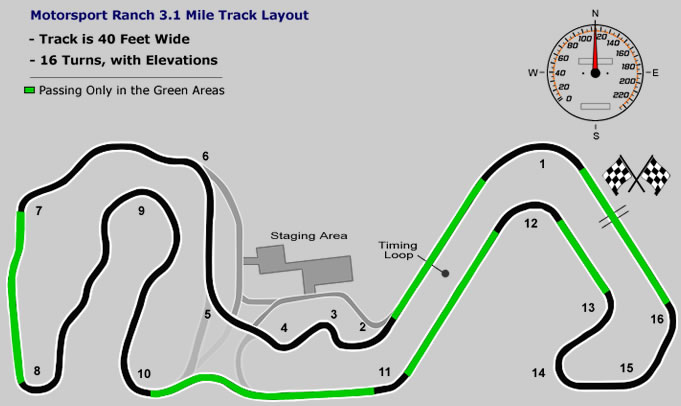

I've been searching for a second video camera setup to use in the BMW, but the new gear didn't show up in time for this MSR-C race. Jon brought his GoPro to use, but we were both so busy all weekend that we didn't set it up in the 330 until after I had turned the car over to him on Sunday. So no in-car TT video of my dismal laps in the 330 this time, sorry. The new vidcam will be here in time for TWS, where we should hopefully have a little more "motion control" in the suspension.

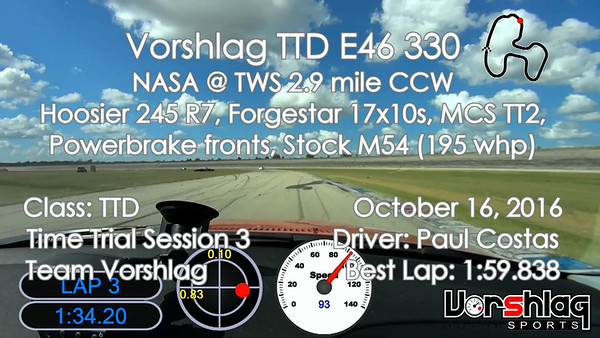

Sunday TT Session 3 in-car video from the TTC C4

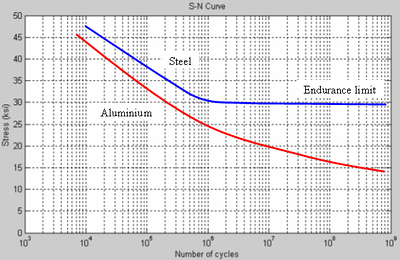

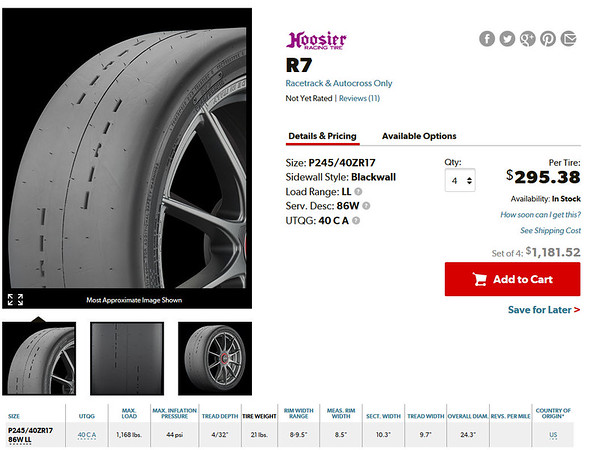

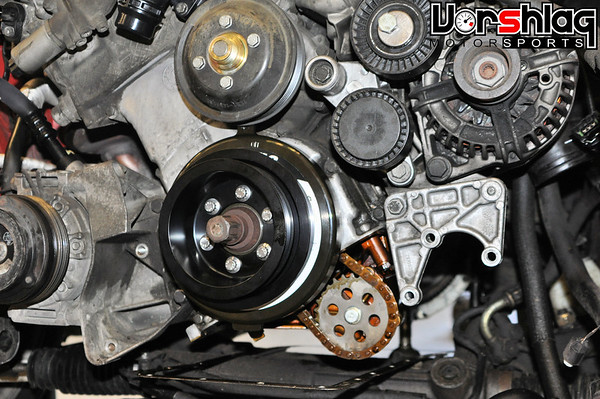

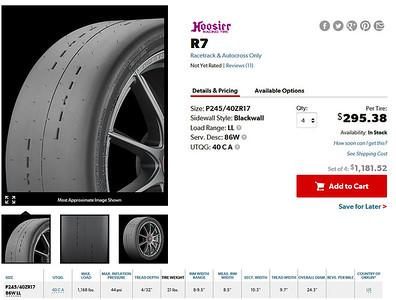

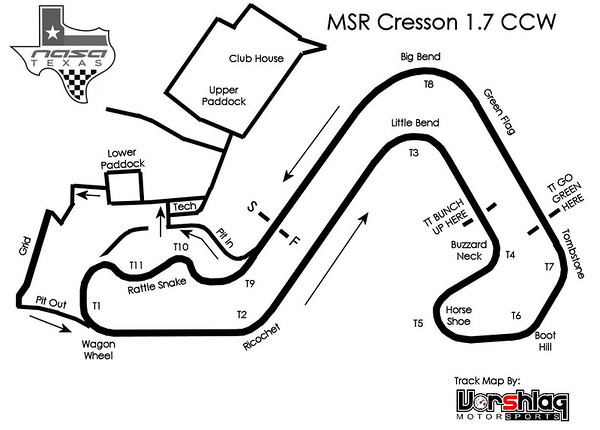

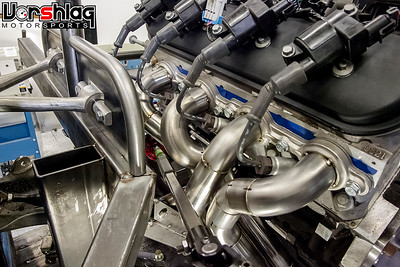

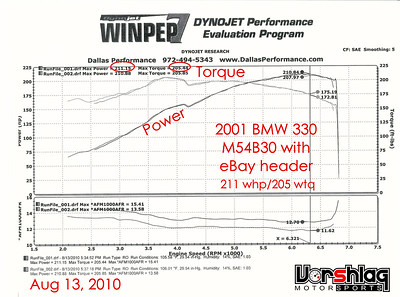

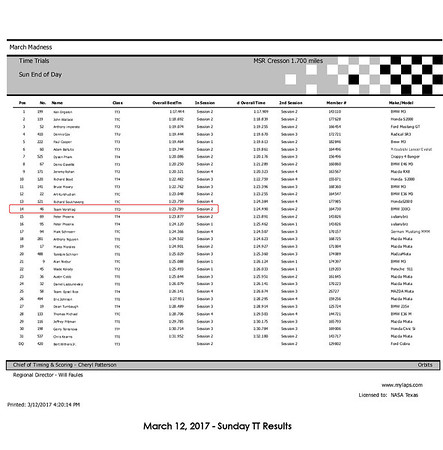

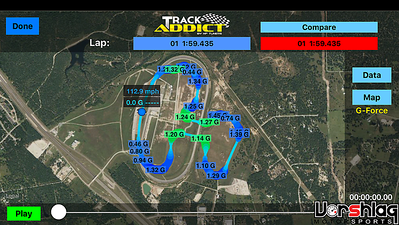

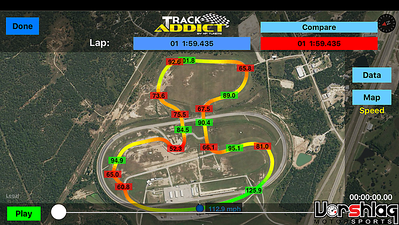

I did make one in-car video from that weekend, in the TTC Corvette, which was considerably faster than our TTD entry. Nothing special here, just showing what this track looks like, one letter class up. With the same driver, the exact same Hoosier 245mm R7 tire and similar weights, and worse brakes, the TTC C4 was nearly 6 seconds a lap quicker than my best TTD lap time. Part of that was me having a little more seat time in the C4, but mostly it came down to SPRING RATE and HORSEPOWER. The C4 is at the class minimum 3260 pounds (it was weighed 12 pounds over in Tech, so 3272) and makes 288 whp (near the class P-to-W limit). The 330 is at 3430 pounds and makes 195 whp (see dyno test below) - which is both 50 whp down and +150 pounds too heavy for TTD class. The C4 also has a massively upgraded 1200# transverse front spring compared to the 350# front coilover springs on the 330.

Obviously we have to address the lack of power, the extra weight, and the low spring rates (and subsequent damper upgrade) needed to make the E46 more competitive in its class. We're into year 2 of prep on the "Budget TTC Corvette", so it has a bit of a head start. We should realistically have been running 1:23s or better in a max effort TTD car, so we have a lot of work left to do to this BMW. We are taking the prep in deliberate, planned stages, so stay tuned for more upgrades as the season progresses and hopefully we can nudge closer to some TTD track records - eventually.

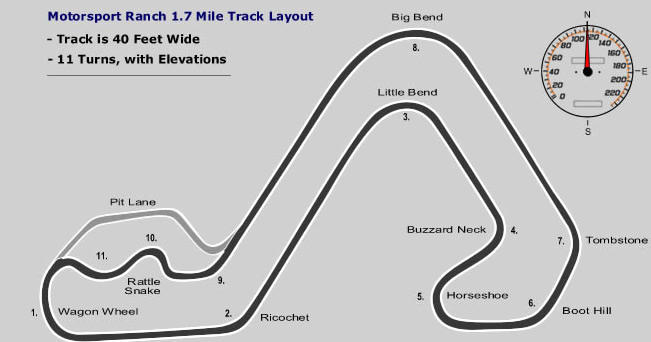

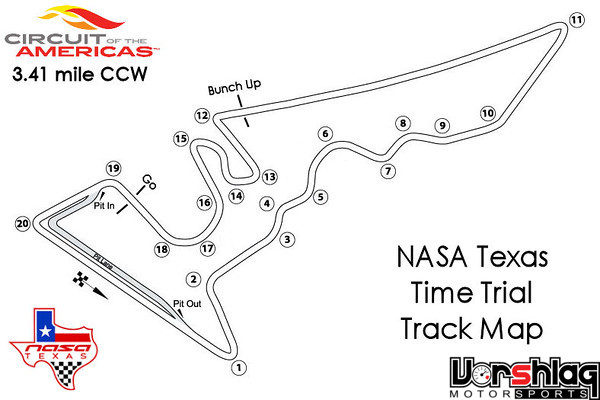

During this NASA weekend I was also instructing, and worked with 4 different HPDE1 students. Sometimes that meant sprinting to the grid to meet them in time for their sessions, after getting out of one of the two TT cars. The grid was way back on the unused 1.3 mile road course, due to the lack of paved parking area on the wet grassy areas. Instructing was fun, but made for a hectic weekend and a lot of running around - I need to get a scooter or small track support vehicle, something to get around the paddock in more quickly. All it takes is money, right?

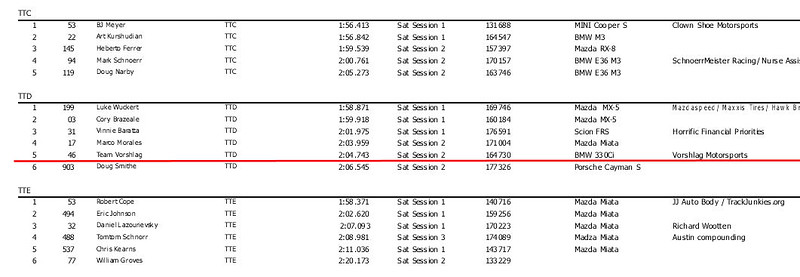

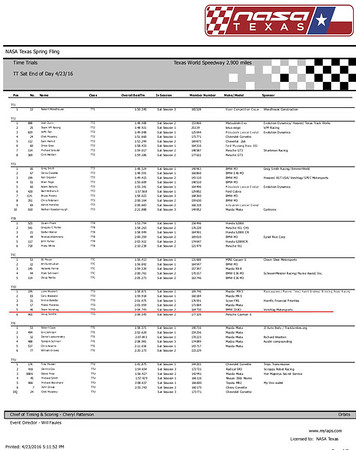

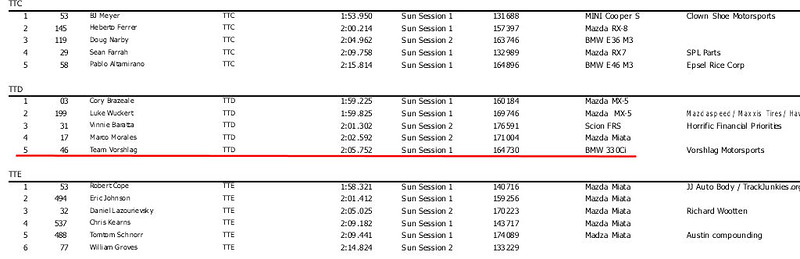

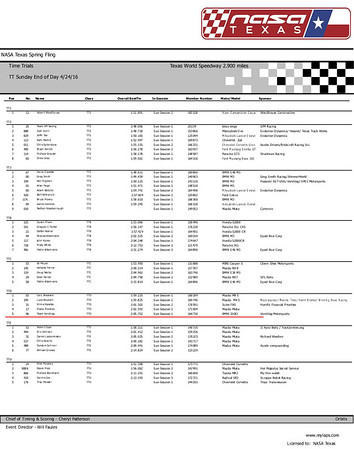

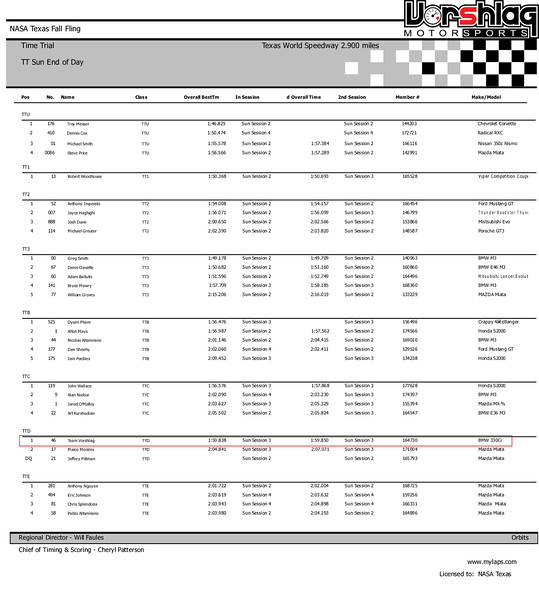

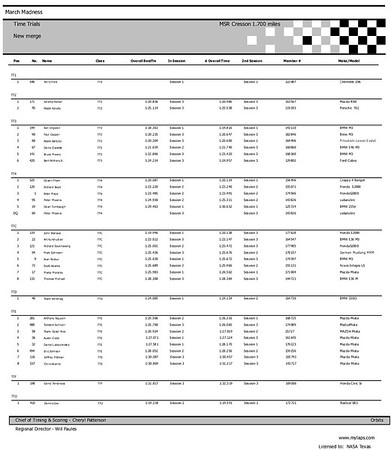

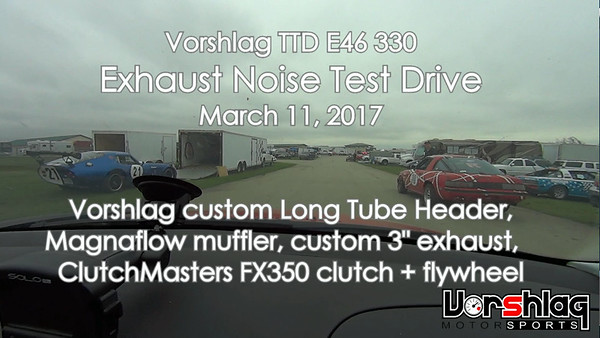

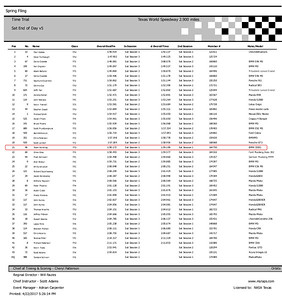

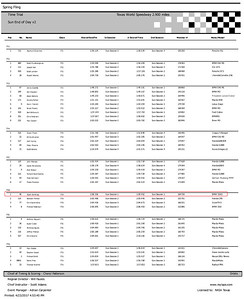

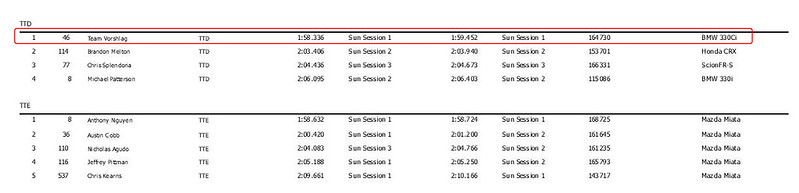

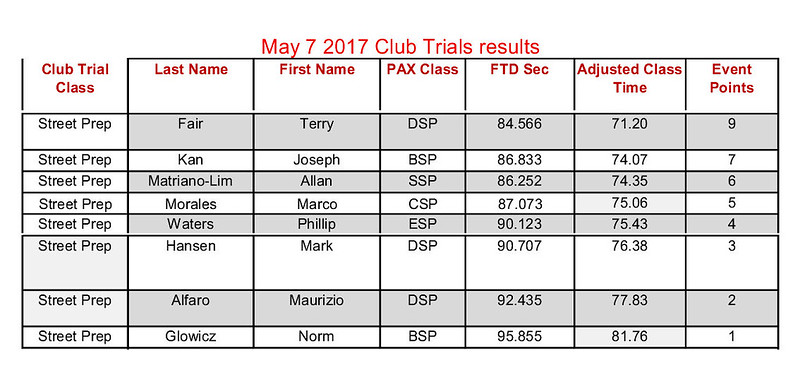

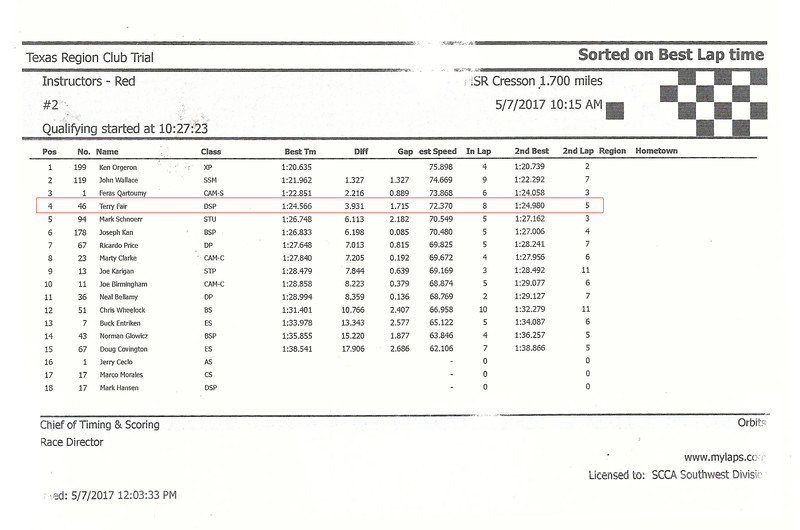

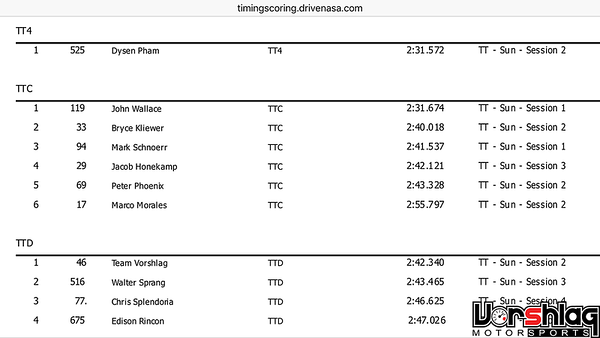

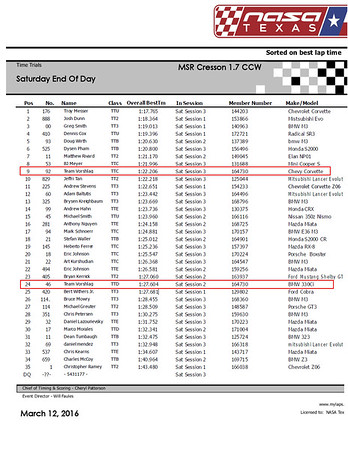

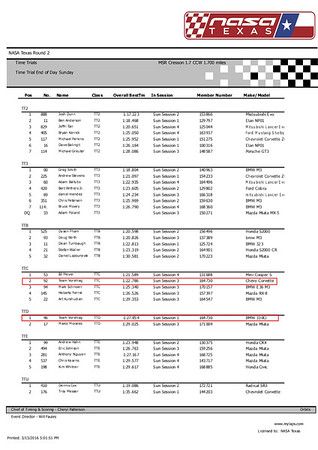

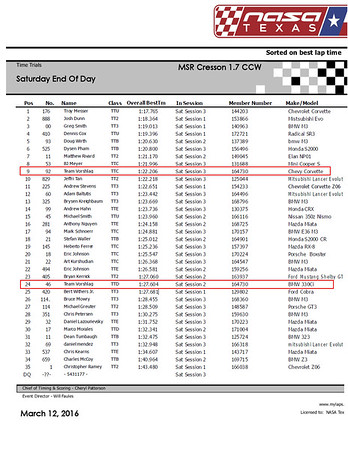

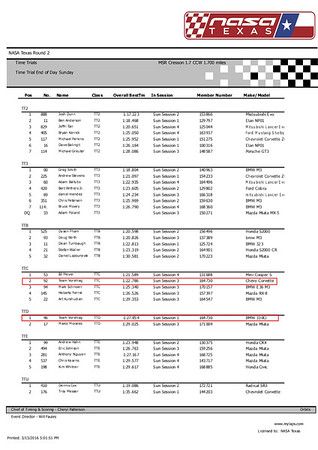

Official results for Saturday (left) and Sunday (right)

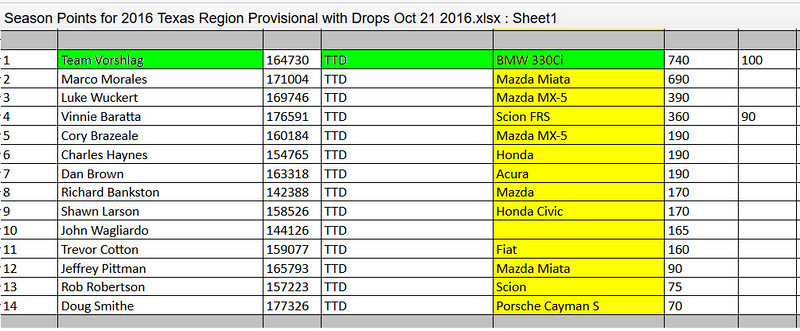

Overall the weekend was a mixed success. Driving two TT cars + instructing + talking to customers at our ever-busy trailer paddock area makes for a hectic weekend, but it was also a lot of fun. Jon got a check ride for TT and should have his comp license the next time he shows up to a NASA event. I managed two 1st place finishes in TTD (with only one timed TT session each day in this very under-prepped car) and two 2nd places in TTC. No new track records set by our cars, but our old TT3 record here (1:17.2) managed to stay untouched - for now.

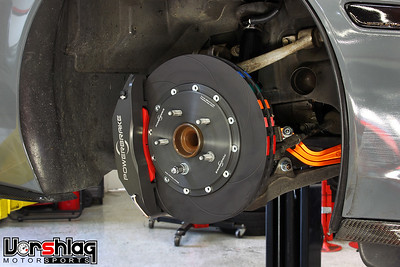

When Jon and I were switching the street tires back onto the 330, we noted that they still had excellent wear across the tread, even with the massive body roll. At least we seem to have the camber, toe and tire pressures dialed in well. Since we didn't win a new set this weekend, I suspect this 6-weekend old set of R7s will be used once again on the 330 at TWS. The front brakes also looked exceptionally good - with virtually no visible pad or rotor wear - and only the first thermal paint band had "turned". That means the rotor had crossed 527° F but had not reached the next band, which is at 860 °F.

I cannot explain with words how GOOD the brakes felt and performed, but I am now a believer. Glad we took the gamble and tried out this new Powerbrake kit on our car. They also flew in for our annual SCCA Tech day + Open House event (shown above) and their rep talked to 200+ people in our shop that day. After that meet-and-great + our recommendations, we've got a half dozen cars lined up for Powerbrake kits - some of which will be new models we have to measure for them.

After switching the tires on the BMW we moved the trailer out of the grassy swamp and onto pavement, then loaded the Corvette for the trip home. After instructing in the last 5:20 pm HPDE session, I didn't get out of there until after 6 pm, and that 2 hour tow home made for a another 12 hour day. But compared to my normal work days, this was a breeze.

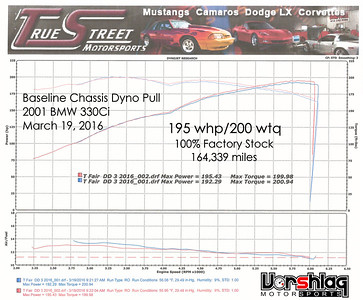

BASELINE DYNO TEST

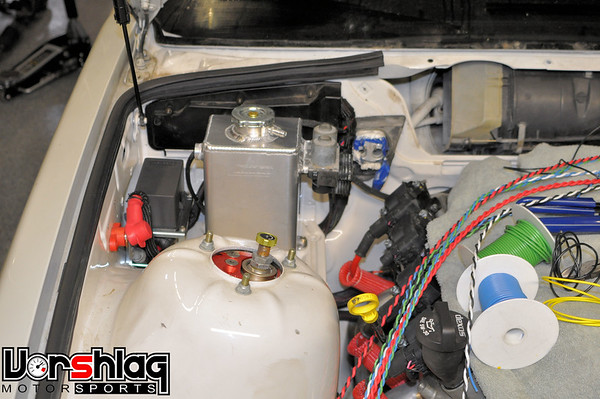

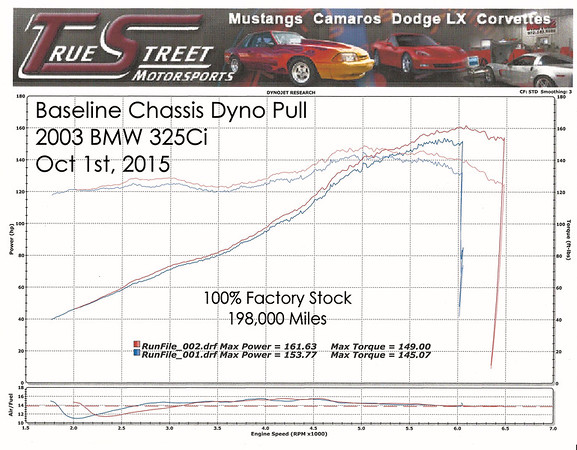

We've been pretty slammed in our shop since the NASA event, but I found time on the next weekend to go to a Dyno Day at True Street Motorsports, who tunes all of the LSx and Coyote 5.0 powered cars we build at our shop. They dyno'd JackDaniels earlier this year, shown above.

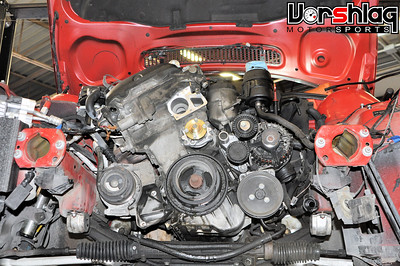

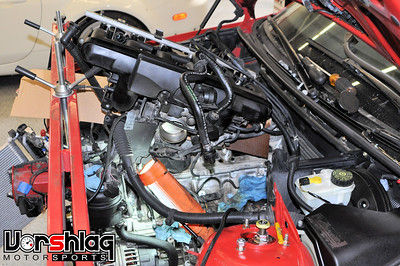

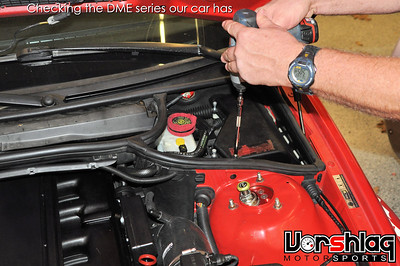

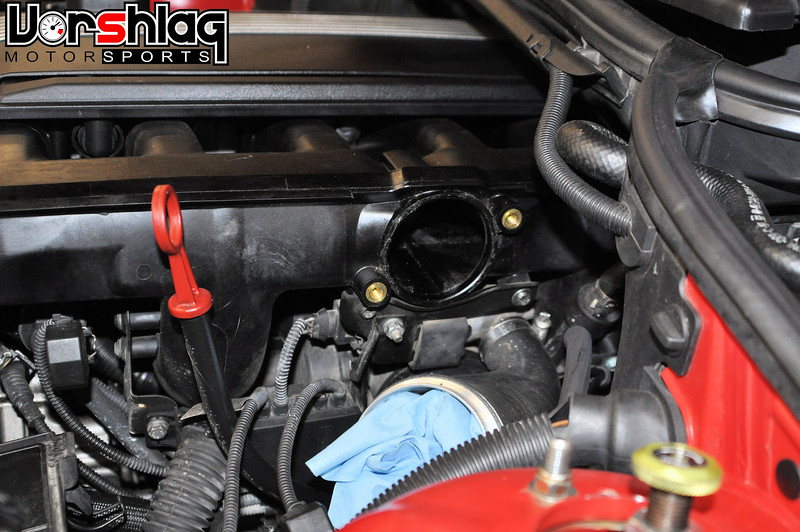

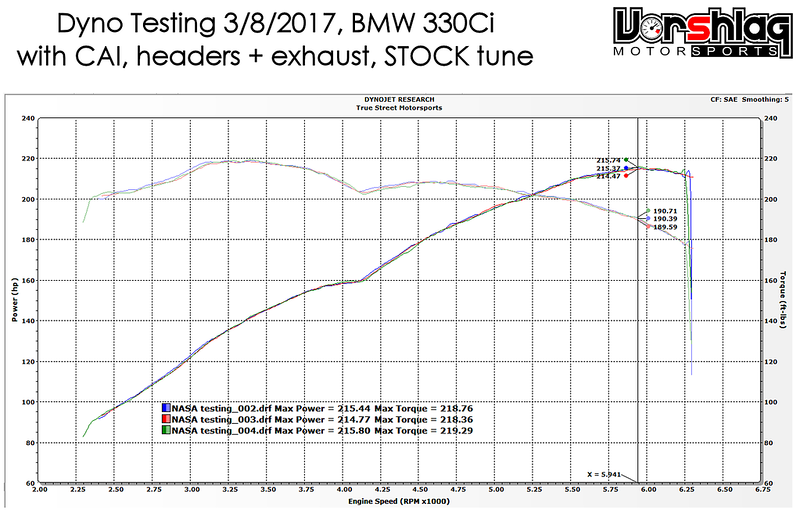

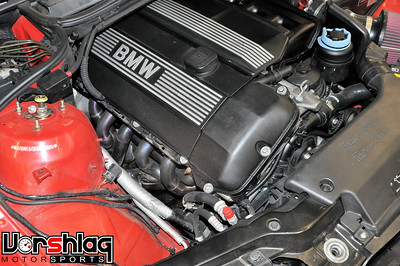

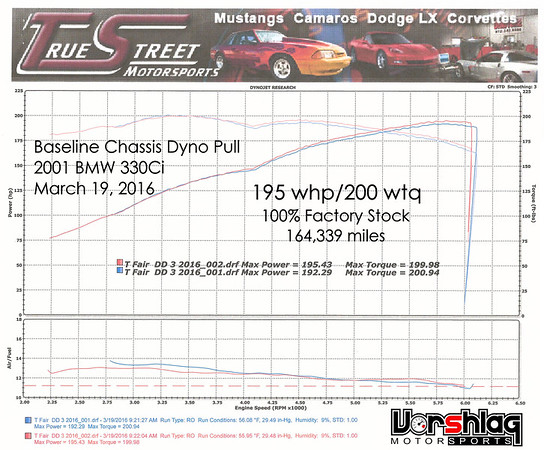

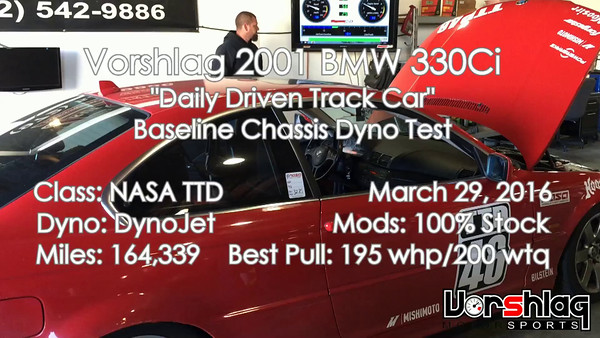

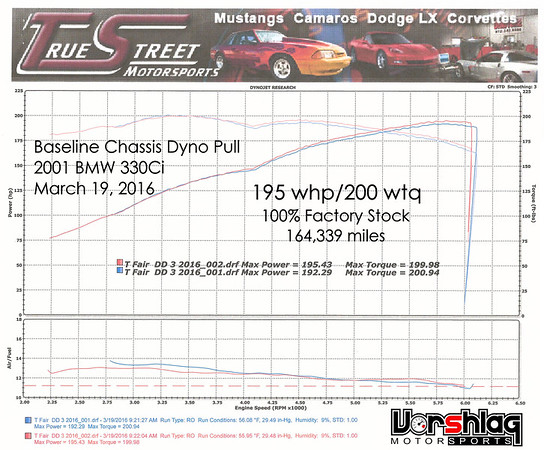

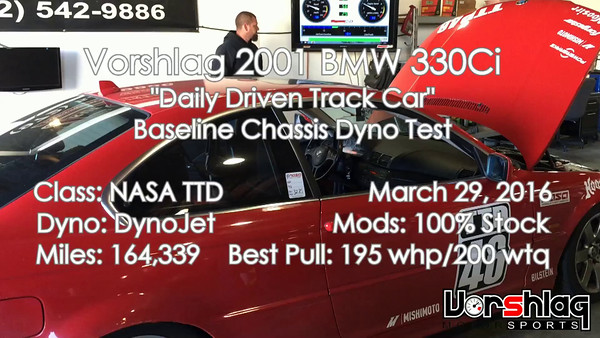

This time I took "Fireball", the red 330, and was first in line for their Dyno Day (they did something like 60 cars that day). We set the bar pretty low that day with our baseline stock dyno pull on this 164K mile 330, but we at least had something to go by for this build!

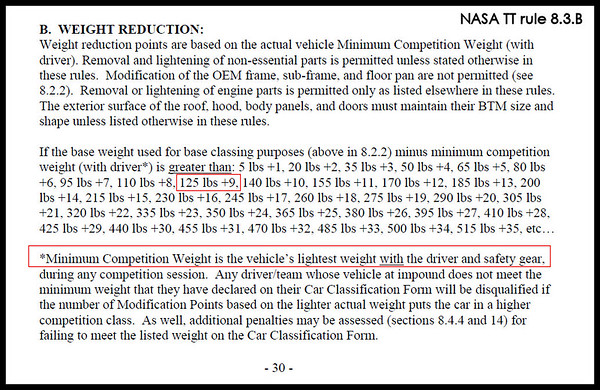

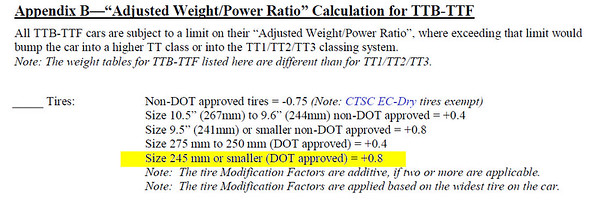

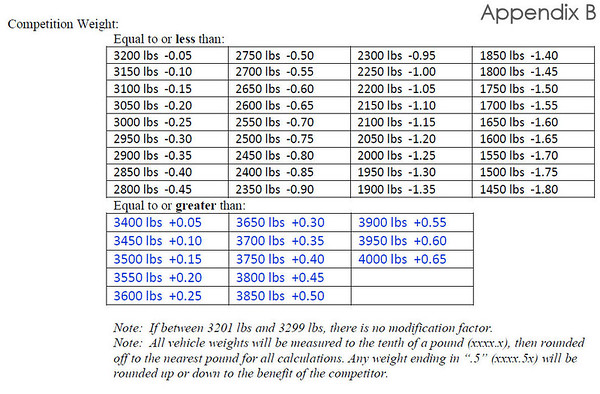

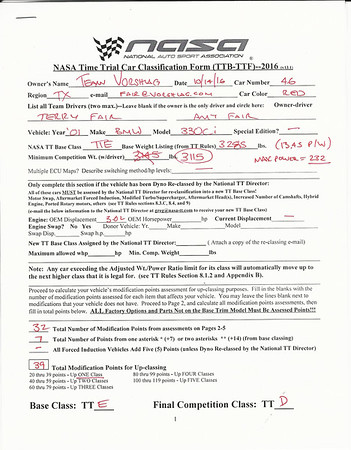

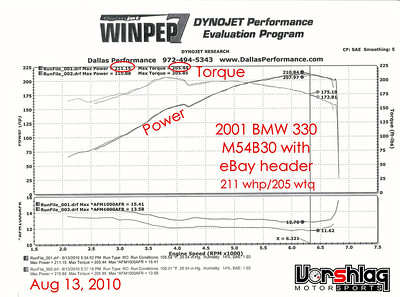

Sure enough, the car made about what I guessed it would on their DynoJet chassis dyno: 195 whp and 200 wtq. Not bad for a bone stock, 16 year old, 164K mile car rated at 225 hp at the crank. As I wrote last time, running at the class minimum weight of 3285 pounds, and with the +0.8 P-to-W "bonus" for running a 245mm tire, we can make up to 244.2 whp in TTD class. Now the real question is... how do we gain 50 whp without burning too many "class points"??

Baseline Dyno Video: https://youtu.be/zAk8xZwOkgg

The underwhelming video above shows parts of the two back-to-back pulls they made on our red BMW. It was done in top gear, revved to 6000 rpm redline, and had a fan blowing over the radiator the whole time. They know how to do NASA certified dyno pulls as they've done them on a half dozen different cars for us. I just wish they had the ability to custom tune the BMW computer.

WHAT'S NEXT?

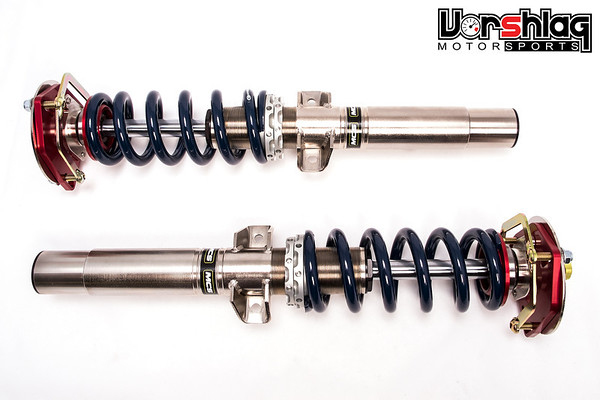

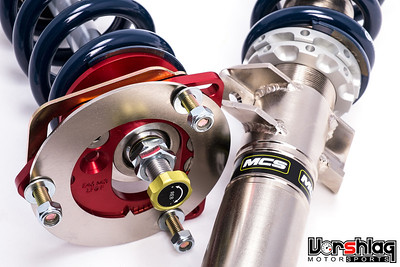

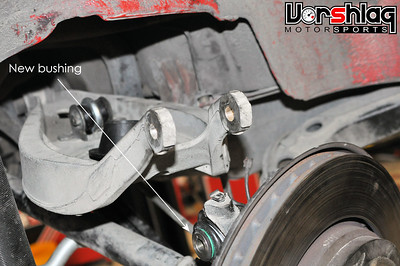

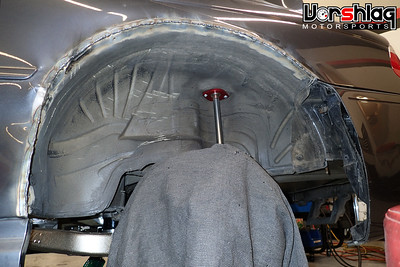

I need to wrap this up so let's see what's next. I ordered MCS TT2 internal double monotube coilovers earlier this week so we can finally get those installed with some REAL spring rates before our next event, which is...

Next few NASA Texas events:

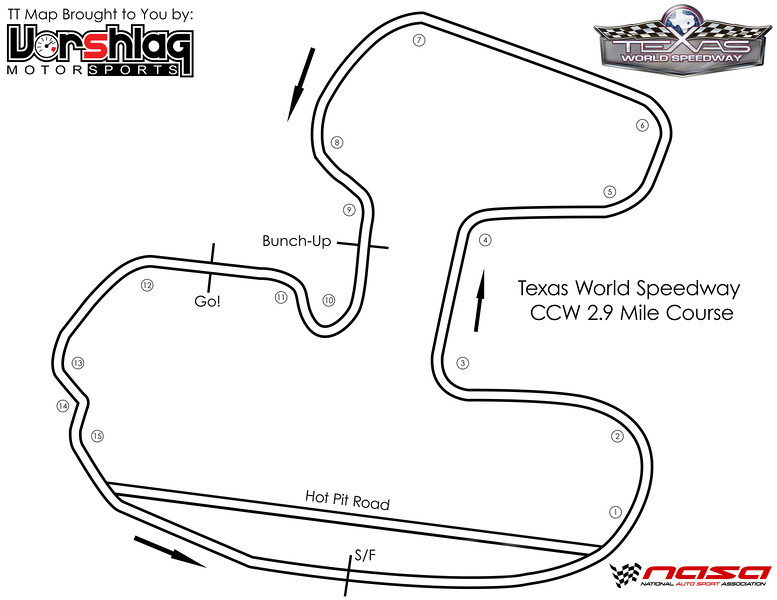

Of course this is the fourth or fifth "last ever" event at TWS, but I don't have much faith in those claims. We'll hopefully have a better sorted suspension to go along with the brakes and tires - both of which worked damned well. We'll still be down on power but we will address that later in the summer. One of the two Whiteline swaybars is en route to us (the rear, ugh) so we'll have to figure out something for the front.

We have TWO more E46 chassis we are going to be building soon, one of them with the PSS suspension coming off of this car. I'll show those builds as they happen in future updates. That's enough for this time. Thanks for reading!

Cheers,

I've been searching for a second video camera setup to use in the BMW, but the new gear didn't show up in time for this MSR-C race. Jon brought his GoPro to use, but we were both so busy all weekend that we didn't set it up in the 330 until after I had turned the car over to him on Sunday. So no in-car TT video of my dismal laps in the 330 this time, sorry. The new vidcam will be here in time for TWS, where we should hopefully have a little more "motion control" in the suspension.

Sunday TT Session 3 in-car video from the TTC C4

I did make one in-car video from that weekend, in the TTC Corvette, which was considerably faster than our TTD entry. Nothing special here, just showing what this track looks like, one letter class up. With the same driver, the exact same Hoosier 245mm R7 tire and similar weights, and worse brakes, the TTC C4 was nearly 6 seconds a lap quicker than my best TTD lap time. Part of that was me having a little more seat time in the C4, but mostly it came down to SPRING RATE and HORSEPOWER. The C4 is at the class minimum 3260 pounds (it was weighed 12 pounds over in Tech, so 3272) and makes 288 whp (near the class P-to-W limit). The 330 is at 3430 pounds and makes 195 whp (see dyno test below) - which is both 50 whp down and +150 pounds too heavy for TTD class. The C4 also has a massively upgraded 1200# transverse front spring compared to the 350# front coilover springs on the 330.

Obviously we have to address the lack of power, the extra weight, and the low spring rates (and subsequent damper upgrade) needed to make the E46 more competitive in its class. We're into year 2 of prep on the "Budget TTC Corvette", so it has a bit of a head start. We should realistically have been running 1:23s or better in a max effort TTD car, so we have a lot of work left to do to this BMW. We are taking the prep in deliberate, planned stages, so stay tuned for more upgrades as the season progresses and hopefully we can nudge closer to some TTD track records - eventually.

During this NASA weekend I was also instructing, and worked with 4 different HPDE1 students. Sometimes that meant sprinting to the grid to meet them in time for their sessions, after getting out of one of the two TT cars. The grid was way back on the unused 1.3 mile road course, due to the lack of paved parking area on the wet grassy areas. Instructing was fun, but made for a hectic weekend and a lot of running around - I need to get a scooter or small track support vehicle, something to get around the paddock in more quickly. All it takes is money, right?

Official results for Saturday (left) and Sunday (right)

Overall the weekend was a mixed success. Driving two TT cars + instructing + talking to customers at our ever-busy trailer paddock area makes for a hectic weekend, but it was also a lot of fun. Jon got a check ride for TT and should have his comp license the next time he shows up to a NASA event. I managed two 1st place finishes in TTD (with only one timed TT session each day in this very under-prepped car) and two 2nd places in TTC. No new track records set by our cars, but our old TT3 record here (1:17.2) managed to stay untouched - for now.

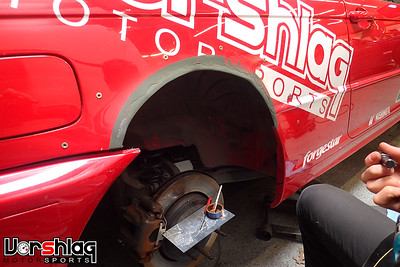

When Jon and I were switching the street tires back onto the 330, we noted that they still had excellent wear across the tread, even with the massive body roll. At least we seem to have the camber, toe and tire pressures dialed in well. Since we didn't win a new set this weekend, I suspect this 6-weekend old set of R7s will be used once again on the 330 at TWS. The front brakes also looked exceptionally good - with virtually no visible pad or rotor wear - and only the first thermal paint band had "turned". That means the rotor had crossed 527° F but had not reached the next band, which is at 860 °F.

I cannot explain with words how GOOD the brakes felt and performed, but I am now a believer. Glad we took the gamble and tried out this new Powerbrake kit on our car. They also flew in for our annual SCCA Tech day + Open House event (shown above) and their rep talked to 200+ people in our shop that day. After that meet-and-great + our recommendations, we've got a half dozen cars lined up for Powerbrake kits - some of which will be new models we have to measure for them.

After switching the tires on the BMW we moved the trailer out of the grassy swamp and onto pavement, then loaded the Corvette for the trip home. After instructing in the last 5:20 pm HPDE session, I didn't get out of there until after 6 pm, and that 2 hour tow home made for a another 12 hour day. But compared to my normal work days, this was a breeze.

BASELINE DYNO TEST

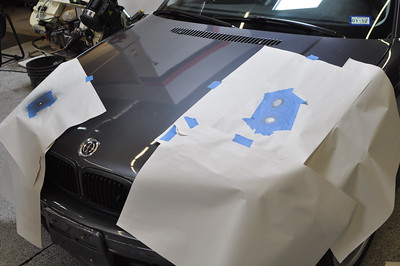

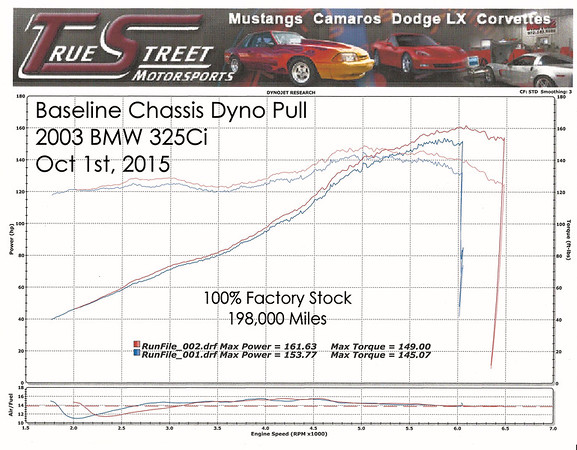

We've been pretty slammed in our shop since the NASA event, but I found time on the next weekend to go to a Dyno Day at True Street Motorsports, who tunes all of the LSx and Coyote 5.0 powered cars we build at our shop. They dyno'd JackDaniels earlier this year, shown above.

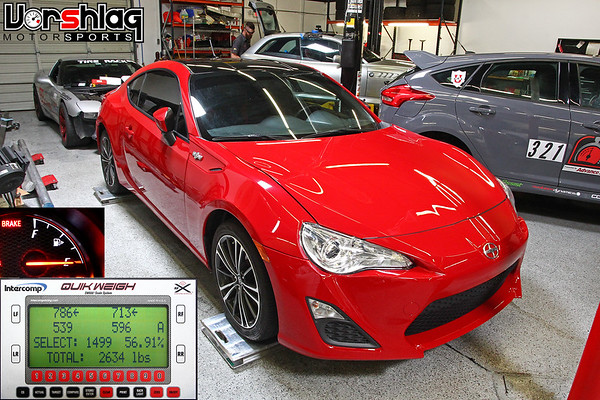

This time I took "Fireball", the red 330, and was first in line for their Dyno Day (they did something like 60 cars that day). We set the bar pretty low that day with our baseline stock dyno pull on this 164K mile 330, but we at least had something to go by for this build!

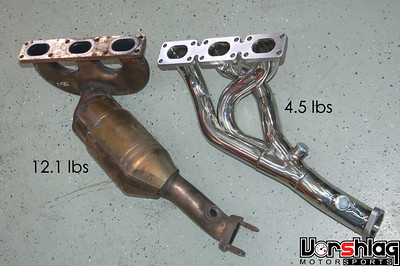

Sure enough, the car made about what I guessed it would on their DynoJet chassis dyno: 195 whp and 200 wtq. Not bad for a bone stock, 16 year old, 164K mile car rated at 225 hp at the crank. As I wrote last time, running at the class minimum weight of 3285 pounds, and with the +0.8 P-to-W "bonus" for running a 245mm tire, we can make up to 244.2 whp in TTD class. Now the real question is... how do we gain 50 whp without burning too many "class points"??

Baseline Dyno Video: https://youtu.be/zAk8xZwOkgg

The underwhelming video above shows parts of the two back-to-back pulls they made on our red BMW. It was done in top gear, revved to 6000 rpm redline, and had a fan blowing over the radiator the whole time. They know how to do NASA certified dyno pulls as they've done them on a half dozen different cars for us. I just wish they had the ability to custom tune the BMW computer.

WHAT'S NEXT?

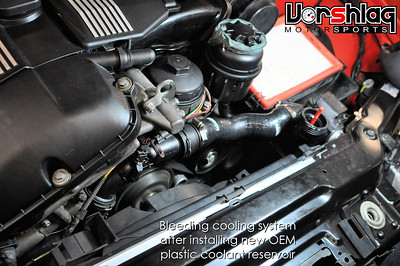

I need to wrap this up so let's see what's next. I ordered MCS TT2 internal double monotube coilovers earlier this week so we can finally get those installed with some REAL spring rates before our next event, which is...

Next few NASA Texas events:

- April 22-24 – Texas World Speedway

- May 21-22 NOLA Motorsports Park – Crossover with NOLA

- June 11-12 – Hallett Motor Racing Circuit

Of course this is the fourth or fifth "last ever" event at TWS, but I don't have much faith in those claims. We'll hopefully have a better sorted suspension to go along with the brakes and tires - both of which worked damned well. We'll still be down on power but we will address that later in the summer. One of the two Whiteline swaybars is en route to us (the rear, ugh) so we'll have to figure out something for the front.

We have TWO more E46 chassis we are going to be building soon, one of them with the PSS suspension coming off of this car. I'll show those builds as they happen in future updates. That's enough for this time. Thanks for reading!

Cheers,