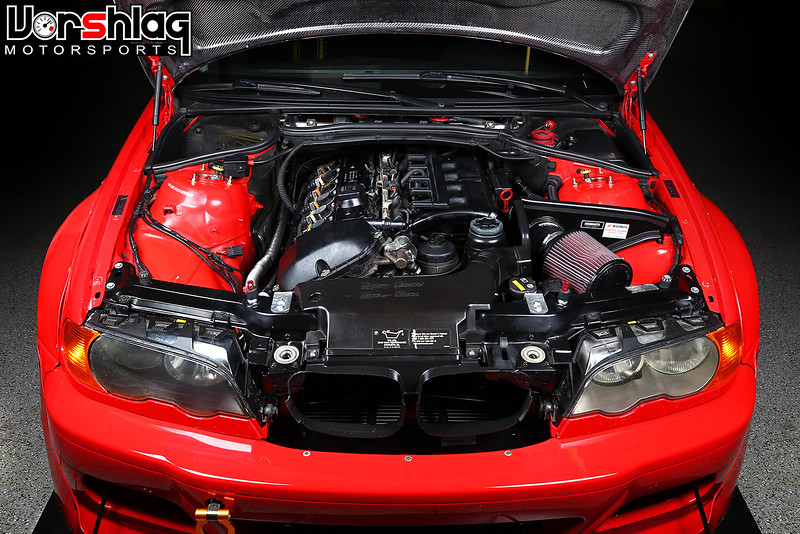

Project update for October 3rd, 2017: I am way behind updating build threads; I need to do about 5 other project updates but I am going to try to do a quick update here. We had a busy summer, which pushed back some work my red TTD prepped 330, but we finally did some upgrades in mid September.

Not only did the front bodywork and aero completely change on the red TTD 330 (above), we completed and sold two of the other E46 cars we have been chronicling in this thread: the 325Ci "Jack Daniels" coupe and the Track Rat 328i sedan (below). This time I will show the final round of work on JD and the 2nd round on the silver 328.

We also picked up another E46 coupe, this black 2003 below. We are just now starting to work on repairing the "little things" to create another "reliable daily driver" for Amy and I to use while some of our other cars are in the shop for upgrades.

I won't talk about the black 325 Coupe above this time, but I will cover work to these other three E46 projects in this post - plus one NASA race weekend - while trying to keep it as brief as possible.

ROUND 317 OF JACK DANIELS REPAIRS + SOLD

This little "whiskey dented" E46 Coupe E46 started this whole build thread, which we named Jack Daniels. It needed a lot of repairs - too many to count - and I lost money on this car due to the purchase price + parts costs alone. I quit counting hours long ago, because it was ugly.

Learned I should have learned long ago - no matter how cheap a car seems up front, starting with a high mileage car coupled with excessive repair costs can bury a project into a money loser right from the beginning. This car needed everything when we bought it with 200K miles: interior work, body work, paint work, suspension work, gaskets/leak fixes, clean-up work, entire cooling system, headlights, and all of the normal things that can plague any high mileage E46.

Even with a shop that specializes in BMWs, and friends in the industry hooking us up on things like PDR repairs, and wholesale pricing on repair parts, I really blew the budget on this one. I won't say how many thousands I lost on this build, but it was enough to notice.

In the end we really cleaned up this little 325 Coupe, and made somebody a nice daily driver that they got with pretty much everything touched or repaired. It had some upgrades that we did when this was going to be our TTD build - the 330 front brakes, Powerflex bushings, etc - and Amy used this is a daily driver off and on for 2 years.

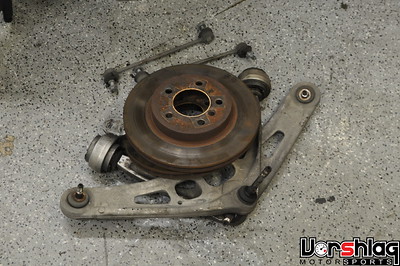

I had people who read this thread that kept calling to try to buy this car for months, but I kept finding things I wasn't happy with and wanted it to leave my shop only when I felt it was "right". So when I drove it recently and felt the rear diff bushing slop, I had our new tech, Aaron, install Powerflex poly diff bushings in all 3 locations (see above). The OEM rubber is just so soft and cracked that this will give whoever buys it less trouble back there.

One nagging thing that kept bugging me was the flaky fuel level gauge. It would only read "full" for a few miles after you topped off the tank, then it would ready empty for 3/4 of the gauge sweep. There are TWO fuel level senders and I ordered the primary one that comes with the new fuel pump, shown above. Our crew swapped that assembly in and it fixed the gauge, whew. Notice also: no more dash lights! We only put 7,000 miles on this car in 2 years, but whenever its logged over 200K it still kills the resale value.

The leather seats (which came from my red 2001 330Ci) needed a bit of work and Brad used LEXOL conditioner to clean and condition the fronts as well as the rear seats. The car was then washed, detailed, vacuumed - cleaner than it ever was while in our possession. I finally felt good about letting this one leave and let the next guy that called have it for a decent price.

When it was time to deliver it to the new buyer he ended up with a lot of repaired systems and a clean, reliable car that is fun to drive for not a lot of money. It won't win any car shows but it should put in many thousands of street miles without too much trouble. It might become the basis for his next WRL endurance race car build in the next few years also. #LongLiveJackDaniels

TRACK RAT GETS SOLD, CUSTOMER WANTS UPGRADES

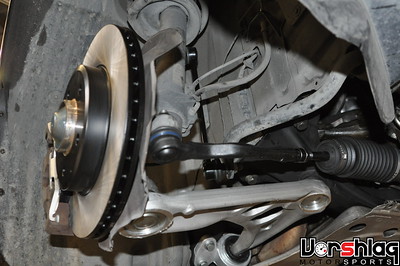

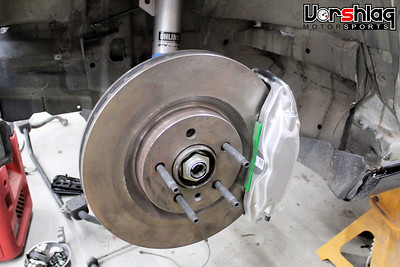

I have talked about the silver Track Rat build in the past. This was a 1999 BMW 328i sedan we bought a while back for another purpose (endurance racing), but when priorities changed I just used this car to fill time in the schedule when our techs weren't on billable work. Which is rare, but still. Last time I showed the 330 front brake upgrade to this car, the Bilstein coilover suspension install, rear subframe reinforcement and bushing upgrades done in late 2016. Let's cover another round of work that happened in 2017: the interior.

INTERIOR: ALUMINUM DOOR PANELS, FLOORS, CONSOLE, ROLL BAR, SEATS

Our crew that started tearing this car apart one weekend (when I wasn't here), to make it into an endurance race car, literally ripped apart and threw away perfectly good interior panels and seats. When we aborted that plan and I decided to make this into a dual purpose street/track car to sell, we needed to keep the windows. Question: how do we cover the door openings on the inside? Answer: fabricate all the things!

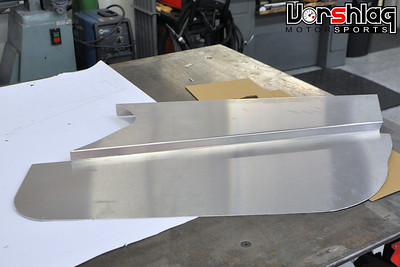

Ryan made some 3D aluminum door panels that tied into the felts at the top and bolt to the doors around the perimeter. These were a little tricky to make and no, we won't likely make a production version. The C shaped cut-out at the front is to clear the dash. The "bump" out of the upper section is to clear the power window motor.

The seats were tossed during the interior removal, too. We stock a lot of race seats here so I had Ryan build brackets and a slider to hold the Sparco Circuit II on the driver's side. Notice how ugly the naked transmission tunnel looks, above?

I got stuck with this unusual and LARGE Momo FIA seat shown above when it didn't fit into a customer's Miata. Plenty of room for wider seats in an E46, so it went into the Track Rat. It uses a fixed mount and fits virtually anyone on the passenger side.

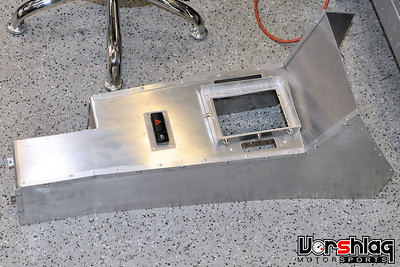

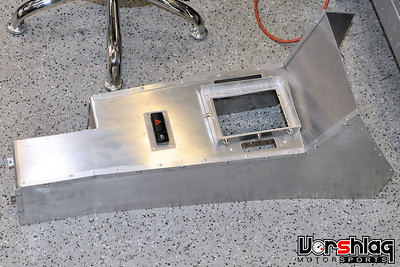

The center console was thrown out also - along with ALL of the window switches, DSC switch, hazard switch, etc. This made me "less than happy" so I had one of our techs make a new center console. It wasn't exactly a fabrication masterpiece but it does the job. Again, this was back when it was just another car we had and I was trying to get it into shape to sell.

The missing switches were purchased (GRR!) and then holes were made to mount them into this aluminum console towards the end of the build. This way the hazards worked, windows rolled up and down, etc. The early E46 uses a DSC button that is different than the late cars... so this was purchased and installed as well (see below). Way too many hours tied up into this aluminum console - if you want to keep it JUST USE THE OEM PLASTICS instead.

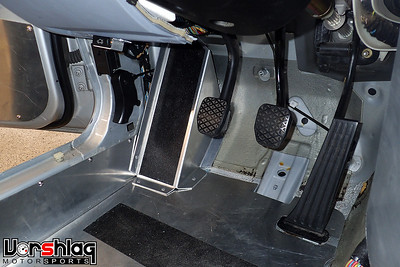

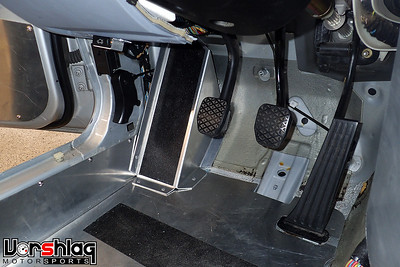

The carpets were gone and with that a lot of padding that covers up a funky floorpan shape and lots of big wiring bundles.

To cover up the "non-flat" floor and hide the wires a pair of "false floors" were built from aluminum sheet. Underneath is a lot of structure to keep them from buckling under the weight of a driver's legs, which is not shown. A custom "Dead pedal" foot rest was added along with some "Grip tape" (above) to keep your shoes from sliding around on the floors when wet.

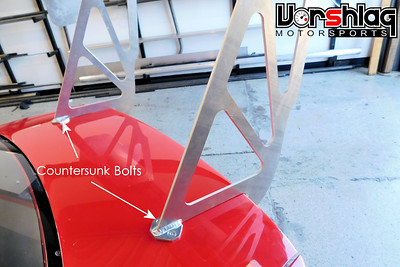

I don't like installing fixed back racing seats into a car without at least a 4-point roll bar. A bolt-in kit was ordered from Kirk Racing, and it shipped in on a flat pallet in pieces. Ryan fitted the roll bar structure to the chassis, tack welded the rear down tubes in place in the car, then removed it to final weld these joints.

The welded assembly was powder coated in a "textured black", then it was bolted into the car. Even the reinforcing backing plates were powder coated before installation. All in all it fits pretty well, with a gap to the roof and B-pillars that allows for this to be installed with a headliner and interior panels. Great place to hang harnesses from...

Well it turns out when you are building a car "on speculation" of selling it, you probably shouldn't install racing seats and assume it will fit the buyer. The Circuit II wasn't the right seat but we had an EVO III in stock that fit him perfectly. This was installed into the Track Rat and the new Circuit II that was in there went into my red 330, which I showed in the last installment. A pair of new Schroth Profi-II 6-point harnesses went in to wrap up the safety/interior bits.

A bit of PDR was done early on in this build to remove some dings and a "wrinkle" in one door panel. Kris did a great job and made this car look pretty sharp - it had good paint, just needed a little massaging.

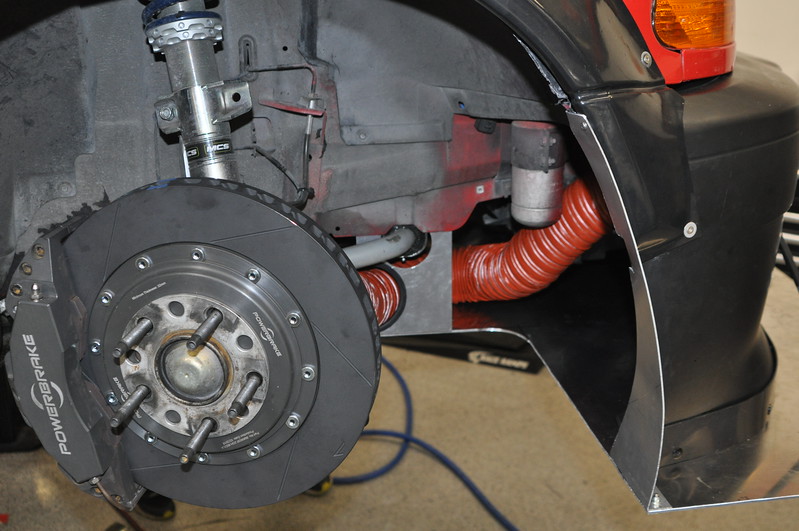

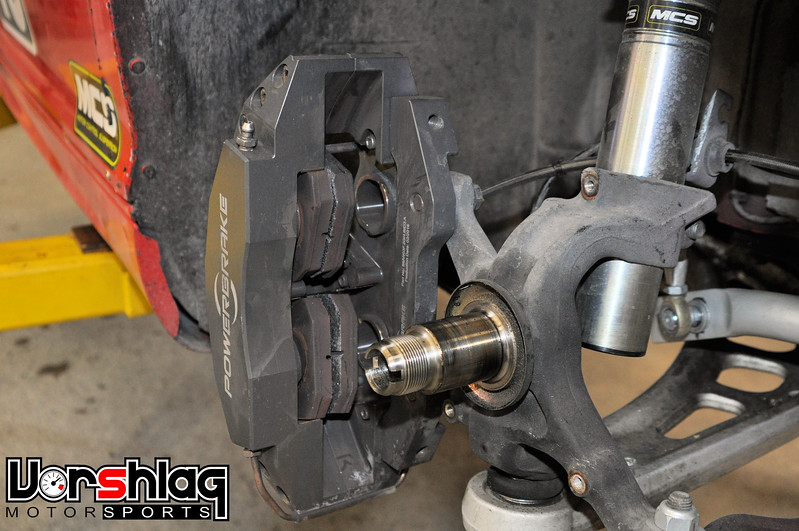

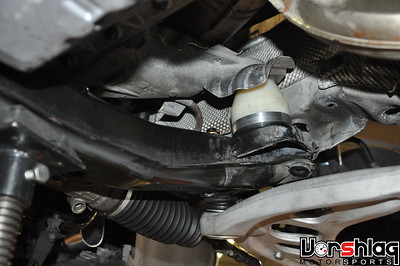

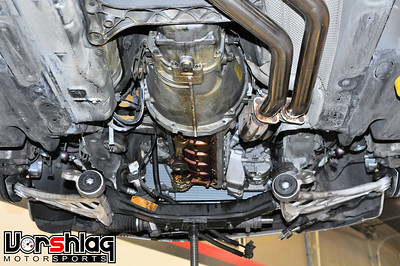

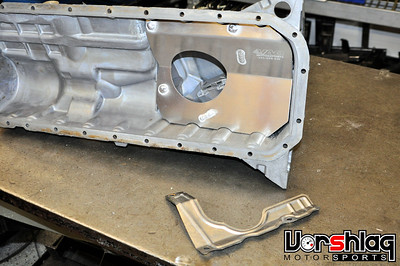

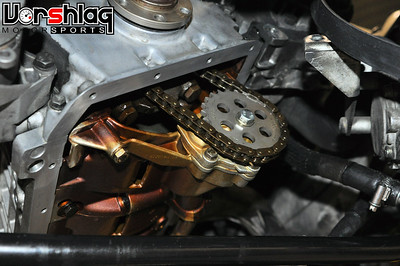

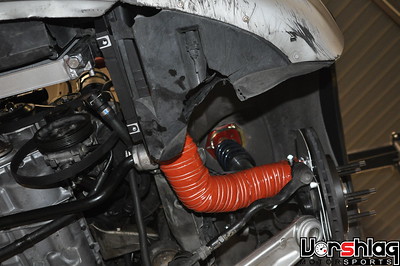

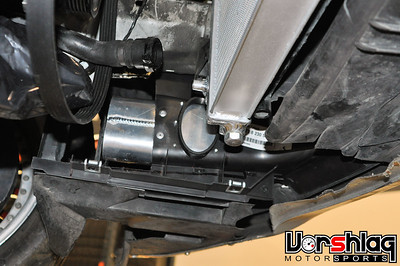

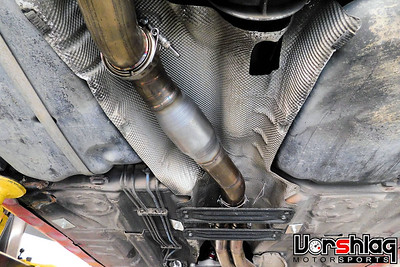

Next time I will show the upgrades the customer asked for after he purchased the car. It now looks like this, above. We have since tackled the wider wheels/tires, flares, oiling system upgrades, cooling system changes, custom brake cooling, new belts/hoses, Vorshlag motor/trans mounts, new Motul fluids, plus some other small repairs and a few more little restoration jobs. This car has already seen track use and the owner loves it. He can drive to the track with cold air and windows up, then get there and let 'er rip. It turned into a more dedicated track car interior, and a better dual purpose build than even our 330...

continued below

Not only did the front bodywork and aero completely change on the red TTD 330 (above), we completed and sold two of the other E46 cars we have been chronicling in this thread: the 325Ci "Jack Daniels" coupe and the Track Rat 328i sedan (below). This time I will show the final round of work on JD and the 2nd round on the silver 328.

We also picked up another E46 coupe, this black 2003 below. We are just now starting to work on repairing the "little things" to create another "reliable daily driver" for Amy and I to use while some of our other cars are in the shop for upgrades.

I won't talk about the black 325 Coupe above this time, but I will cover work to these other three E46 projects in this post - plus one NASA race weekend - while trying to keep it as brief as possible.

ROUND 317 OF JACK DANIELS REPAIRS + SOLD

This little "whiskey dented" E46 Coupe E46 started this whole build thread, which we named Jack Daniels. It needed a lot of repairs - too many to count - and I lost money on this car due to the purchase price + parts costs alone. I quit counting hours long ago, because it was ugly.

Learned I should have learned long ago - no matter how cheap a car seems up front, starting with a high mileage car coupled with excessive repair costs can bury a project into a money loser right from the beginning. This car needed everything when we bought it with 200K miles: interior work, body work, paint work, suspension work, gaskets/leak fixes, clean-up work, entire cooling system, headlights, and all of the normal things that can plague any high mileage E46.

Even with a shop that specializes in BMWs, and friends in the industry hooking us up on things like PDR repairs, and wholesale pricing on repair parts, I really blew the budget on this one. I won't say how many thousands I lost on this build, but it was enough to notice.

In the end we really cleaned up this little 325 Coupe, and made somebody a nice daily driver that they got with pretty much everything touched or repaired. It had some upgrades that we did when this was going to be our TTD build - the 330 front brakes, Powerflex bushings, etc - and Amy used this is a daily driver off and on for 2 years.

I had people who read this thread that kept calling to try to buy this car for months, but I kept finding things I wasn't happy with and wanted it to leave my shop only when I felt it was "right". So when I drove it recently and felt the rear diff bushing slop, I had our new tech, Aaron, install Powerflex poly diff bushings in all 3 locations (see above). The OEM rubber is just so soft and cracked that this will give whoever buys it less trouble back there.

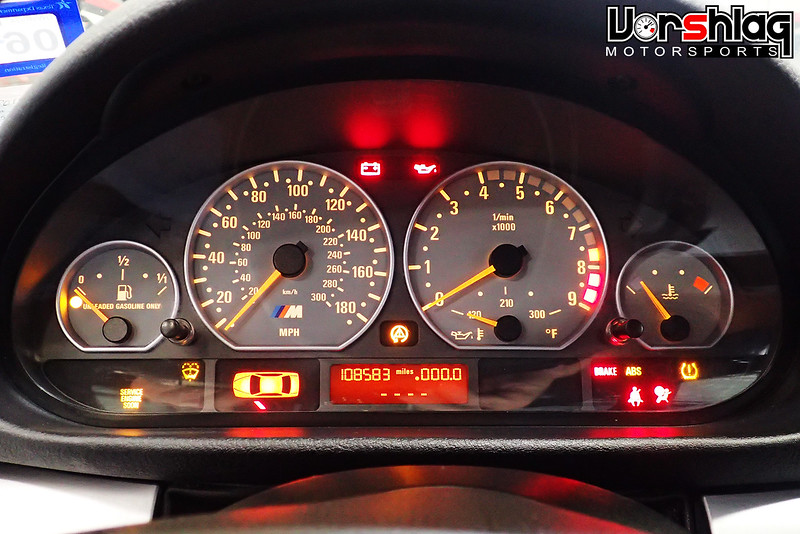

One nagging thing that kept bugging me was the flaky fuel level gauge. It would only read "full" for a few miles after you topped off the tank, then it would ready empty for 3/4 of the gauge sweep. There are TWO fuel level senders and I ordered the primary one that comes with the new fuel pump, shown above. Our crew swapped that assembly in and it fixed the gauge, whew. Notice also: no more dash lights! We only put 7,000 miles on this car in 2 years, but whenever its logged over 200K it still kills the resale value.

The leather seats (which came from my red 2001 330Ci) needed a bit of work and Brad used LEXOL conditioner to clean and condition the fronts as well as the rear seats. The car was then washed, detailed, vacuumed - cleaner than it ever was while in our possession. I finally felt good about letting this one leave and let the next guy that called have it for a decent price.

When it was time to deliver it to the new buyer he ended up with a lot of repaired systems and a clean, reliable car that is fun to drive for not a lot of money. It won't win any car shows but it should put in many thousands of street miles without too much trouble. It might become the basis for his next WRL endurance race car build in the next few years also. #LongLiveJackDaniels

TRACK RAT GETS SOLD, CUSTOMER WANTS UPGRADES

I have talked about the silver Track Rat build in the past. This was a 1999 BMW 328i sedan we bought a while back for another purpose (endurance racing), but when priorities changed I just used this car to fill time in the schedule when our techs weren't on billable work. Which is rare, but still. Last time I showed the 330 front brake upgrade to this car, the Bilstein coilover suspension install, rear subframe reinforcement and bushing upgrades done in late 2016. Let's cover another round of work that happened in 2017: the interior.

INTERIOR: ALUMINUM DOOR PANELS, FLOORS, CONSOLE, ROLL BAR, SEATS

Our crew that started tearing this car apart one weekend (when I wasn't here), to make it into an endurance race car, literally ripped apart and threw away perfectly good interior panels and seats. When we aborted that plan and I decided to make this into a dual purpose street/track car to sell, we needed to keep the windows. Question: how do we cover the door openings on the inside? Answer: fabricate all the things!

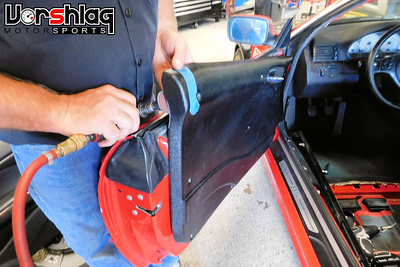

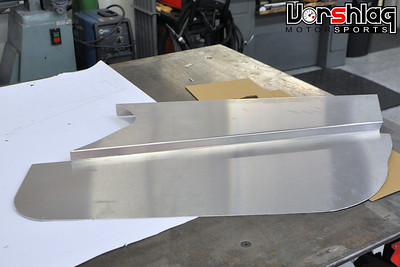

Ryan made some 3D aluminum door panels that tied into the felts at the top and bolt to the doors around the perimeter. These were a little tricky to make and no, we won't likely make a production version. The C shaped cut-out at the front is to clear the dash. The "bump" out of the upper section is to clear the power window motor.

The seats were tossed during the interior removal, too. We stock a lot of race seats here so I had Ryan build brackets and a slider to hold the Sparco Circuit II on the driver's side. Notice how ugly the naked transmission tunnel looks, above?

I got stuck with this unusual and LARGE Momo FIA seat shown above when it didn't fit into a customer's Miata. Plenty of room for wider seats in an E46, so it went into the Track Rat. It uses a fixed mount and fits virtually anyone on the passenger side.

The center console was thrown out also - along with ALL of the window switches, DSC switch, hazard switch, etc. This made me "less than happy" so I had one of our techs make a new center console. It wasn't exactly a fabrication masterpiece but it does the job. Again, this was back when it was just another car we had and I was trying to get it into shape to sell.

The missing switches were purchased (GRR!) and then holes were made to mount them into this aluminum console towards the end of the build. This way the hazards worked, windows rolled up and down, etc. The early E46 uses a DSC button that is different than the late cars... so this was purchased and installed as well (see below). Way too many hours tied up into this aluminum console - if you want to keep it JUST USE THE OEM PLASTICS instead.

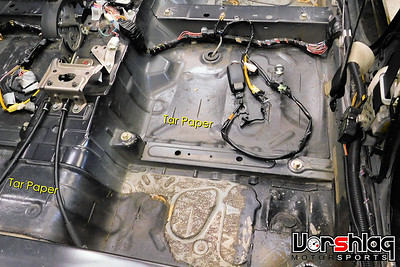

The carpets were gone and with that a lot of padding that covers up a funky floorpan shape and lots of big wiring bundles.

To cover up the "non-flat" floor and hide the wires a pair of "false floors" were built from aluminum sheet. Underneath is a lot of structure to keep them from buckling under the weight of a driver's legs, which is not shown. A custom "Dead pedal" foot rest was added along with some "Grip tape" (above) to keep your shoes from sliding around on the floors when wet.

I don't like installing fixed back racing seats into a car without at least a 4-point roll bar. A bolt-in kit was ordered from Kirk Racing, and it shipped in on a flat pallet in pieces. Ryan fitted the roll bar structure to the chassis, tack welded the rear down tubes in place in the car, then removed it to final weld these joints.

The welded assembly was powder coated in a "textured black", then it was bolted into the car. Even the reinforcing backing plates were powder coated before installation. All in all it fits pretty well, with a gap to the roof and B-pillars that allows for this to be installed with a headliner and interior panels. Great place to hang harnesses from...

Well it turns out when you are building a car "on speculation" of selling it, you probably shouldn't install racing seats and assume it will fit the buyer. The Circuit II wasn't the right seat but we had an EVO III in stock that fit him perfectly. This was installed into the Track Rat and the new Circuit II that was in there went into my red 330, which I showed in the last installment. A pair of new Schroth Profi-II 6-point harnesses went in to wrap up the safety/interior bits.

A bit of PDR was done early on in this build to remove some dings and a "wrinkle" in one door panel. Kris did a great job and made this car look pretty sharp - it had good paint, just needed a little massaging.

Next time I will show the upgrades the customer asked for after he purchased the car. It now looks like this, above. We have since tackled the wider wheels/tires, flares, oiling system upgrades, cooling system changes, custom brake cooling, new belts/hoses, Vorshlag motor/trans mounts, new Motul fluids, plus some other small repairs and a few more little restoration jobs. This car has already seen track use and the owner loves it. He can drive to the track with cold air and windows up, then get there and let 'er rip. It turned into a more dedicated track car interior, and a better dual purpose build than even our 330...

continued below