I started the main tear down today and was going good until I couldn't find my torx plus set. One cannot be located anywhere near me at the moment so I am at a stopping point for right now until I find a t45 torx plus bit, I am not even going to try to attempt to take it off with a regular torx, there is just way to much slop.

But as far as continuing with the teardown..

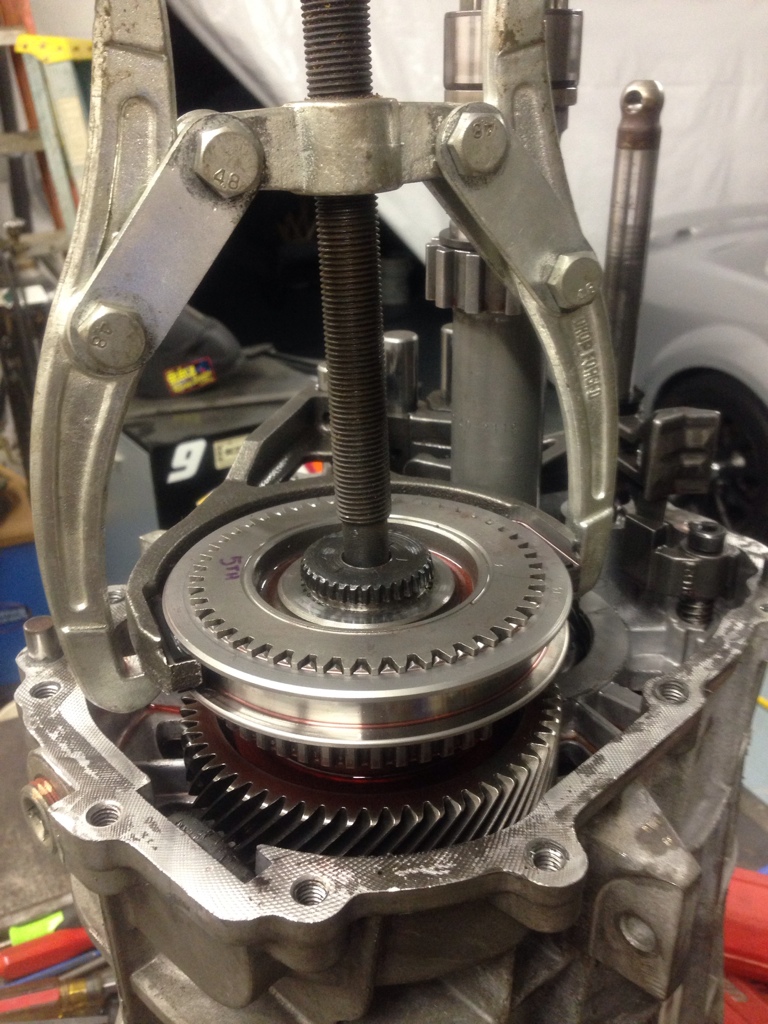

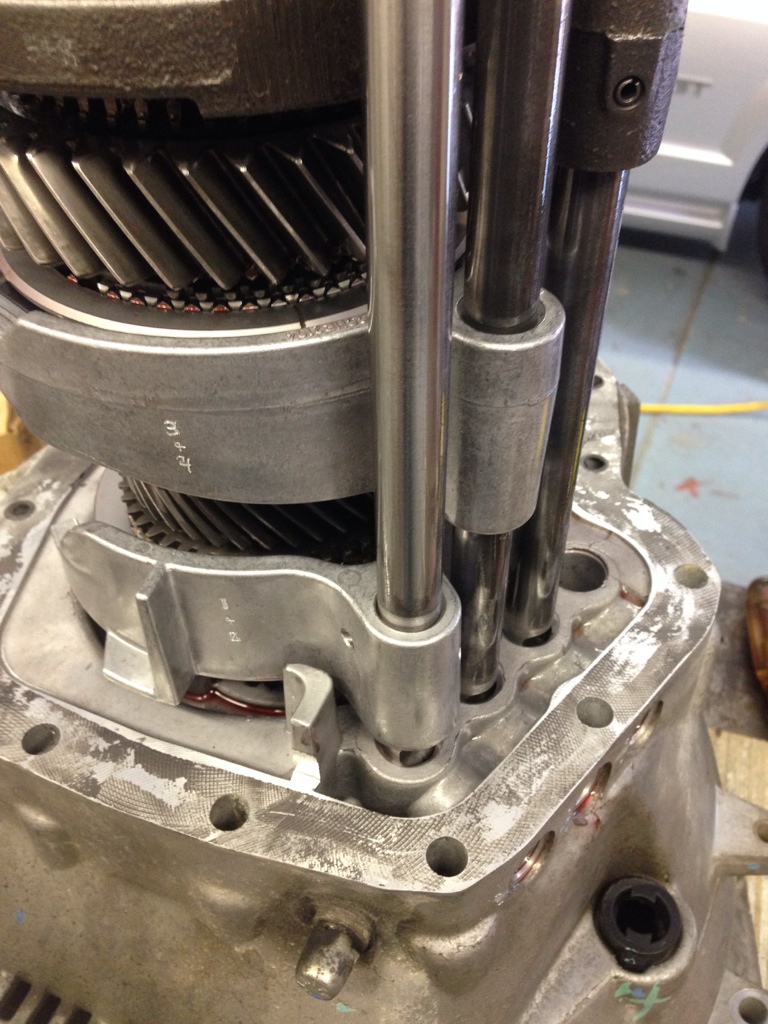

After the tailshaft housing off you have to remove the 5th gear synchronizer cone and assembly off. To do this you will need a 2 lever puller, place one arm on each side of the fork, I didn't want to mess up the threading of the counter shaft so I stuck a bolt and that's what the puller pried on as I tightened it up. While doing this be sure to lift the fork arm at the rail or you will bend a rail while removing this.

After the assembly is off 5th will slide right off and out of your way with the synchro.

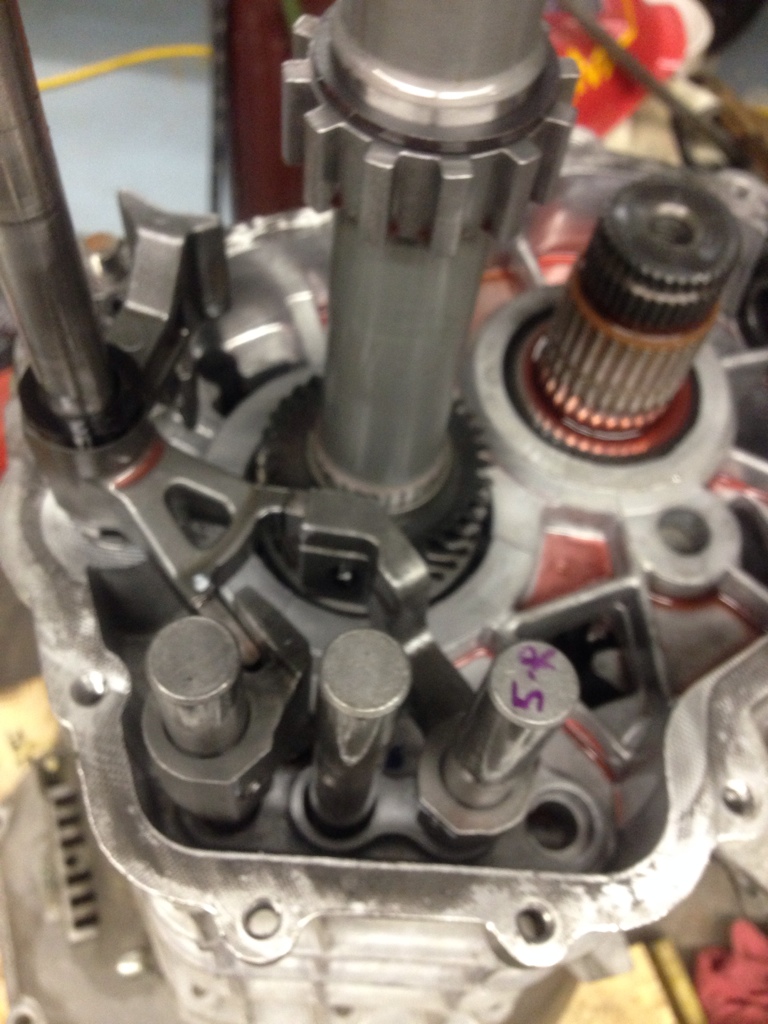

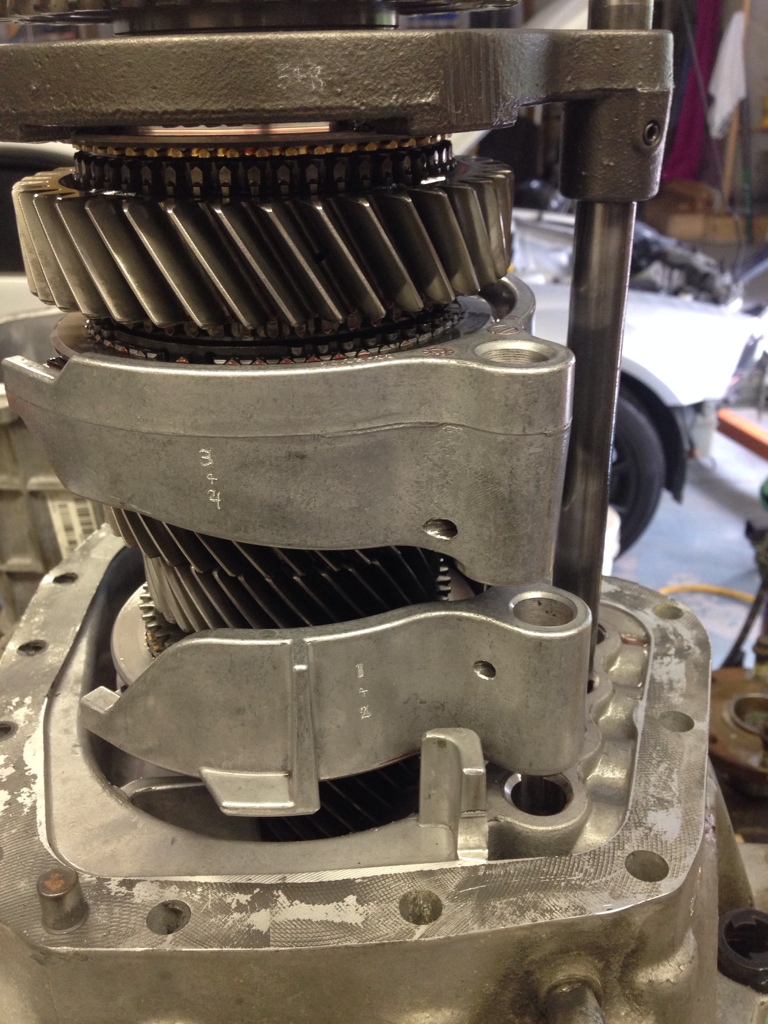

Next is to use a drift/punch to remove the pins holding the shift gates on the rails, remove 5th, 3rd & 4th, 1st & 2nd and then I went back and got the bottom gate off of reverse last.

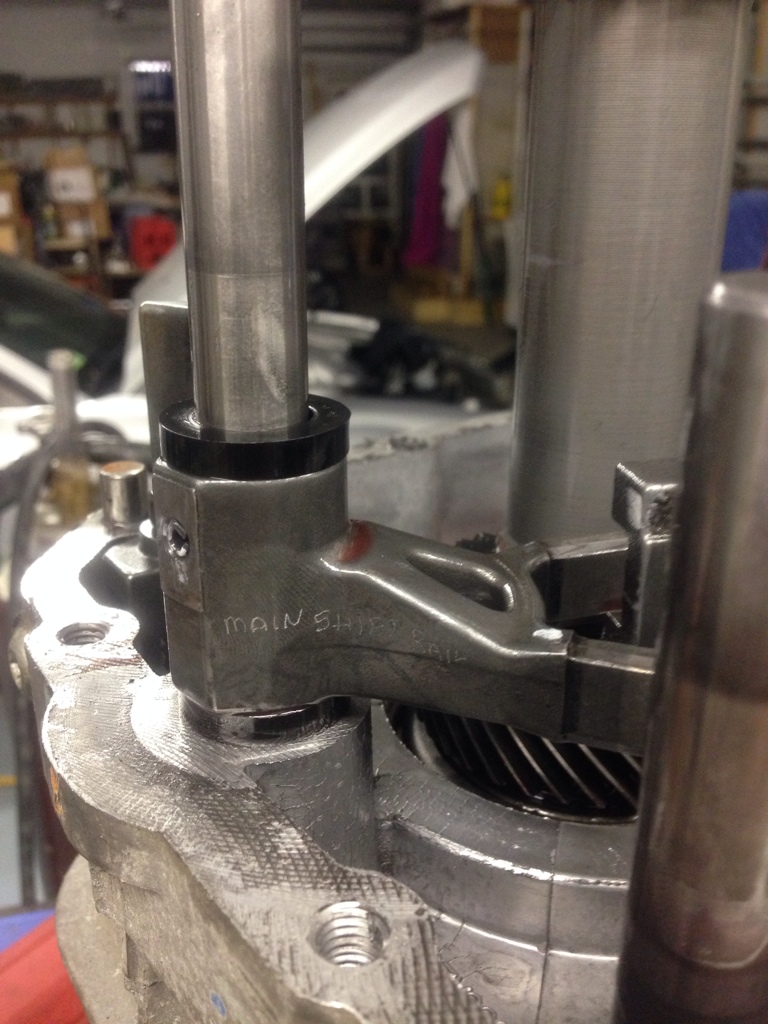

After the gates are removed, remove the main shift gate, it will slide right out and there will be a plastic spacer/washer on each side as pictured.

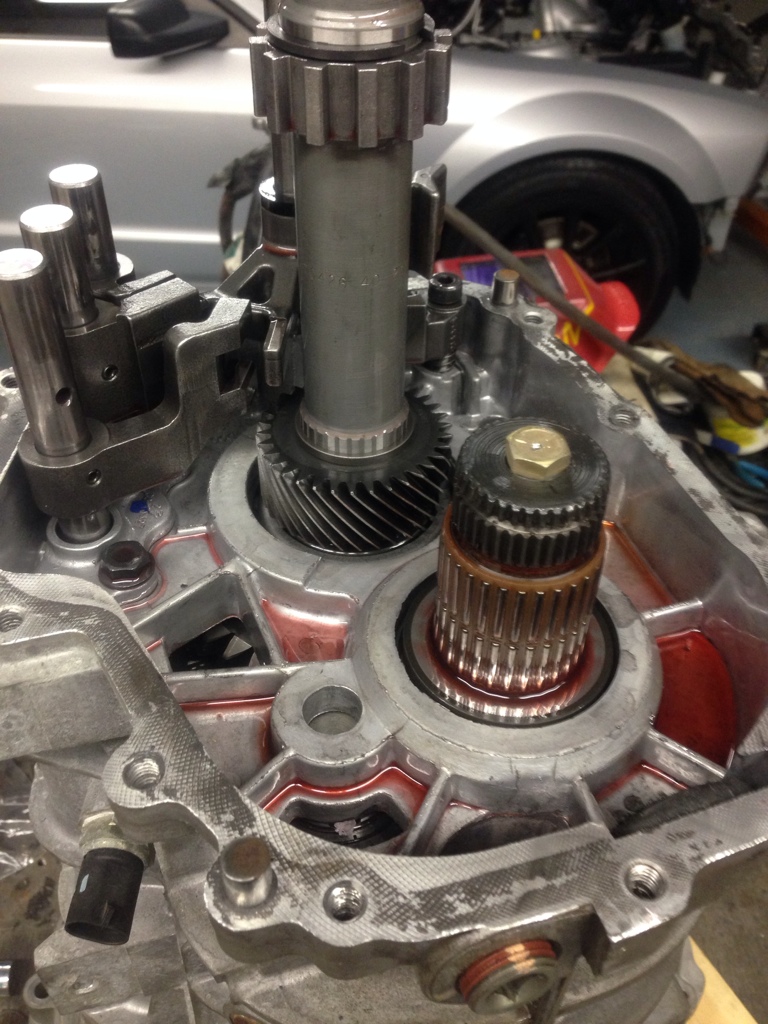

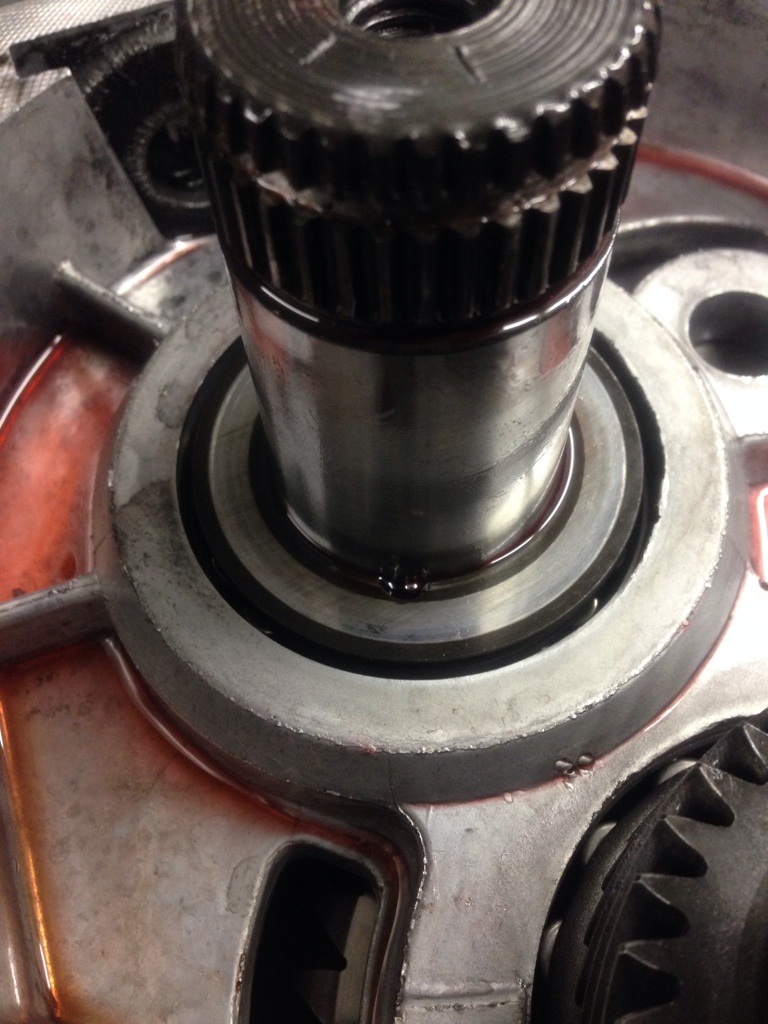

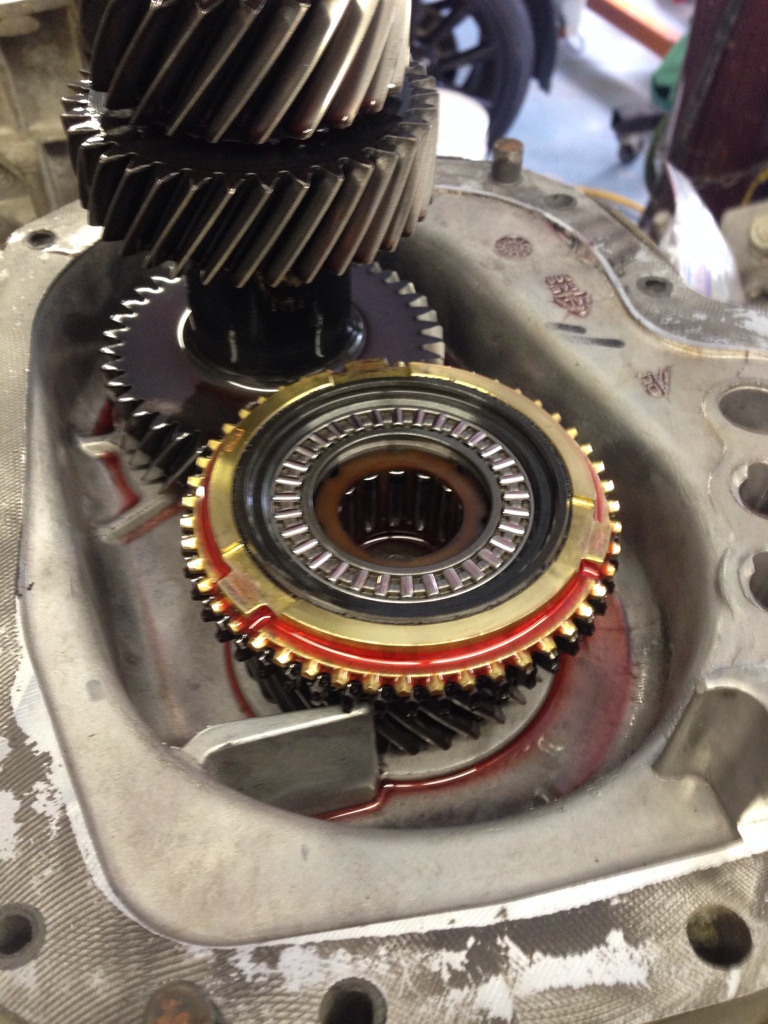

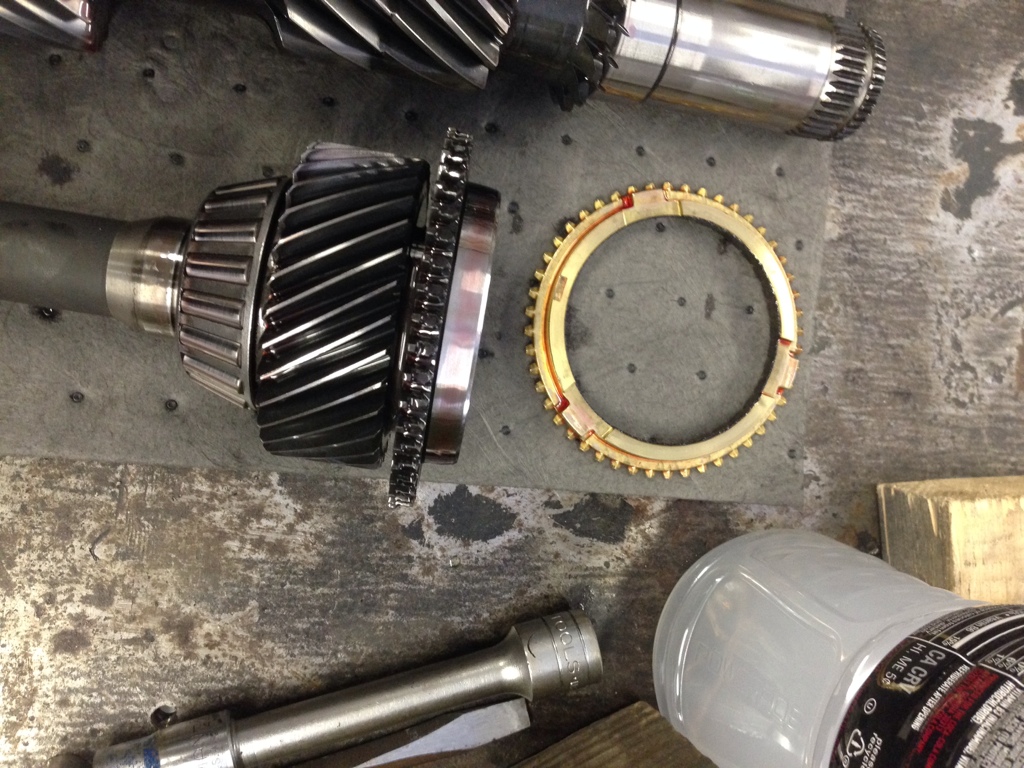

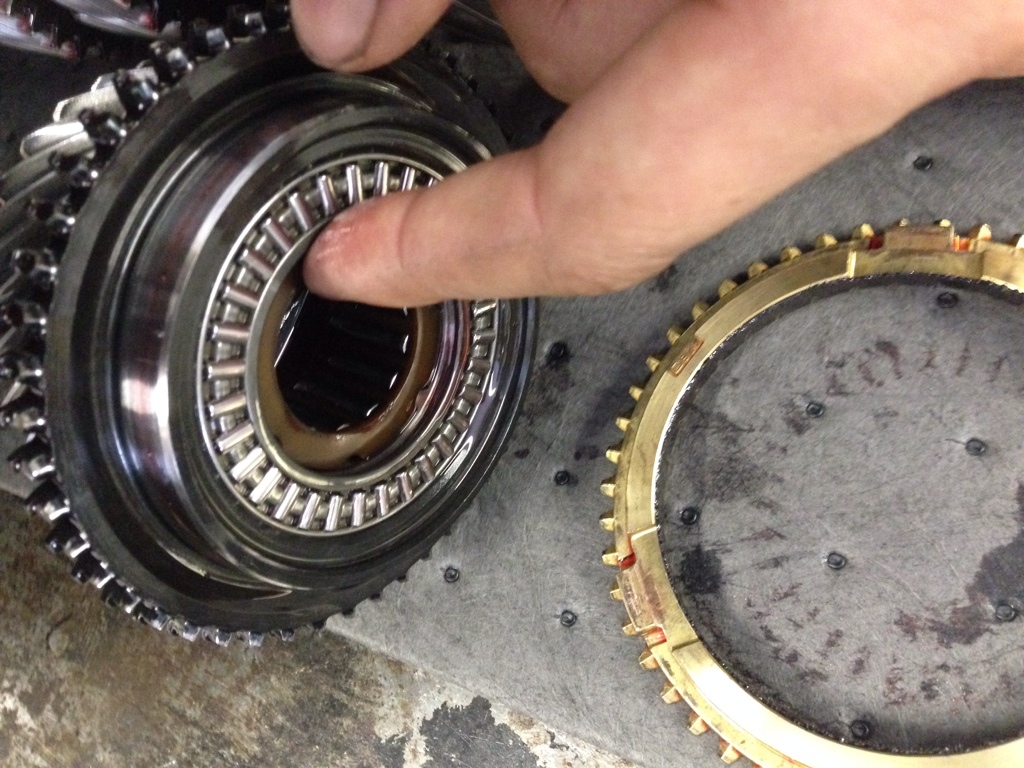

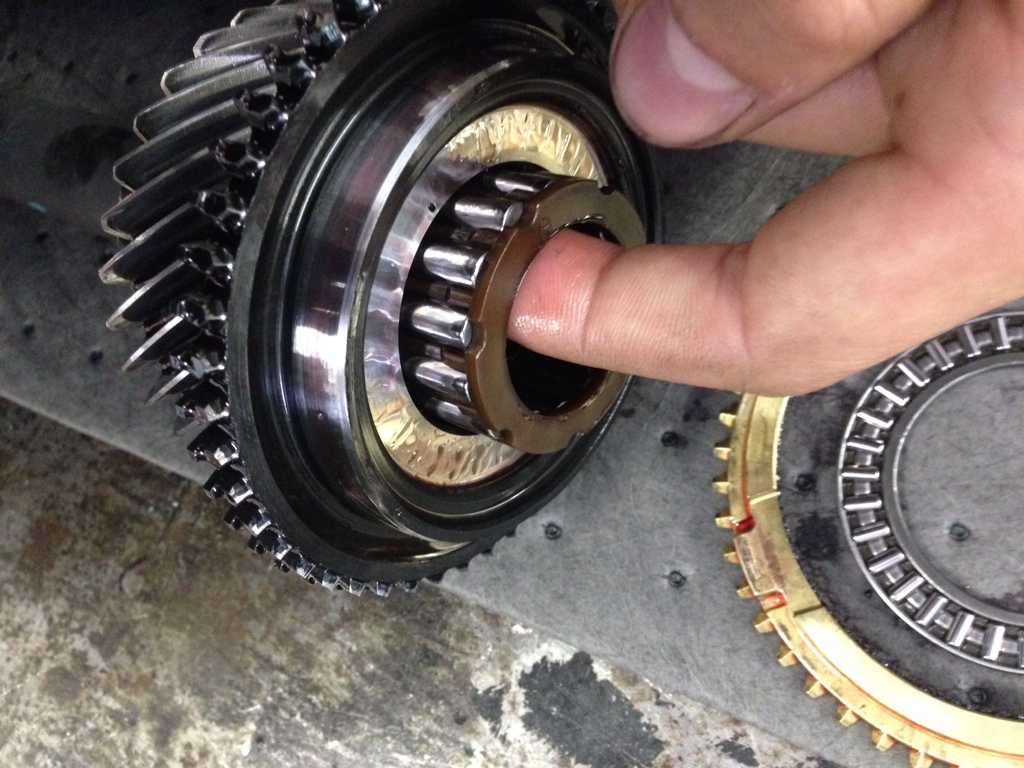

Once those are out move to the other side where the counter shaft is and remove the needle bearing assembly (it will side right up), washer and check ball. (Do use a magnet to get the check ball or you will lose it).

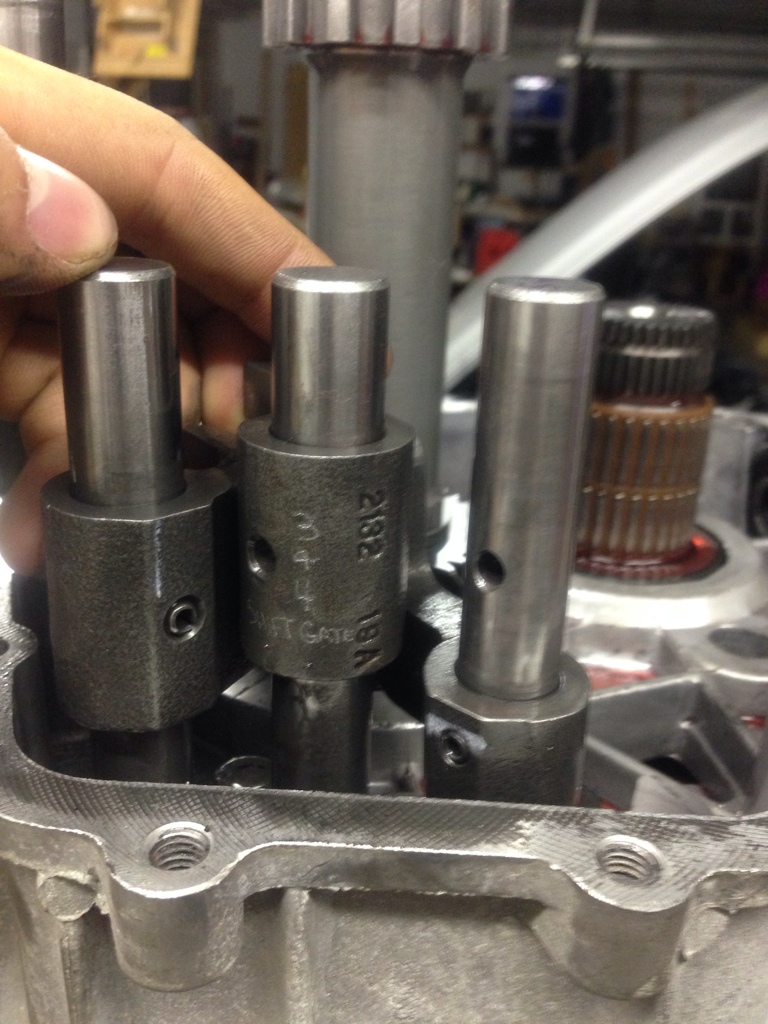

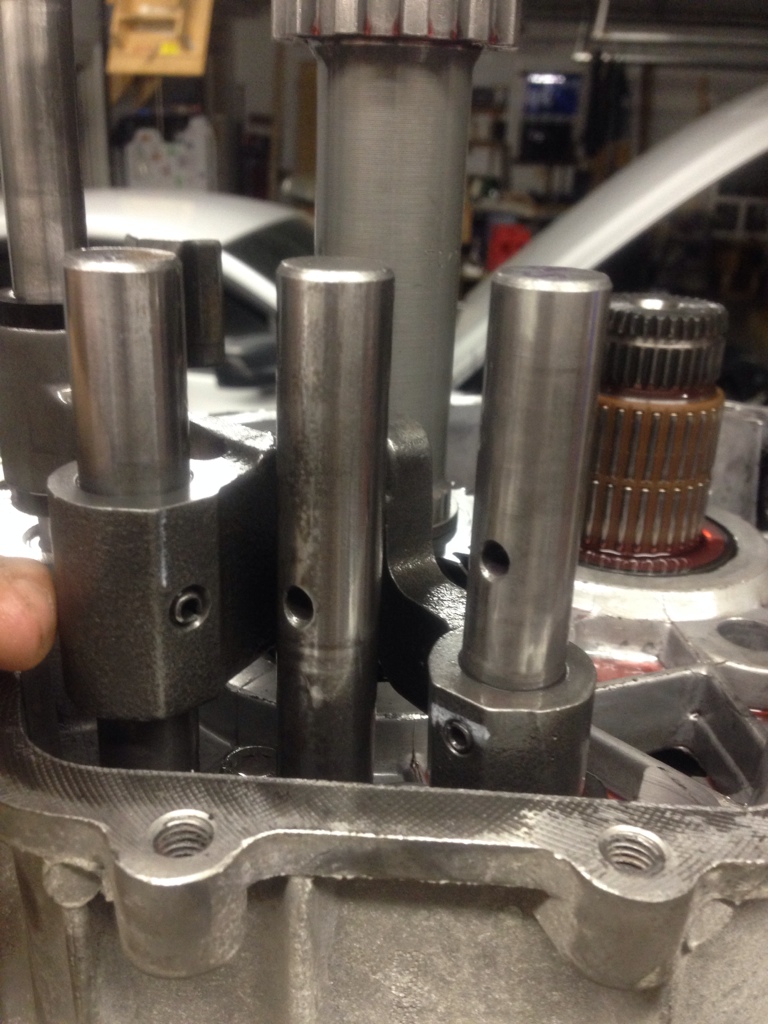

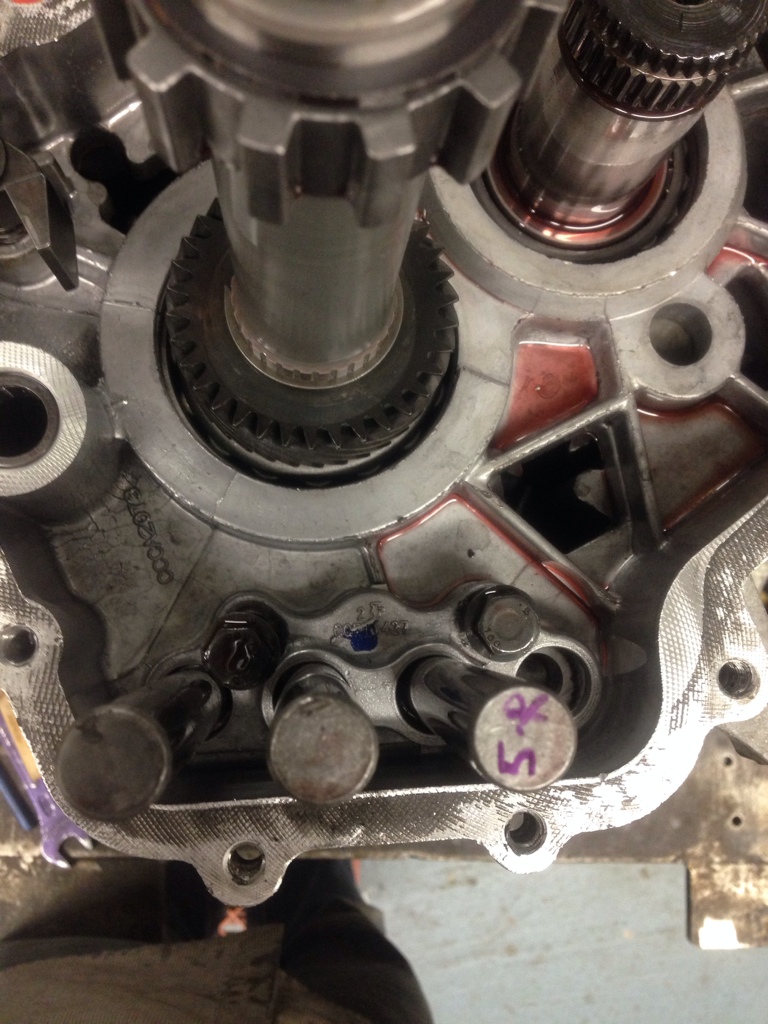

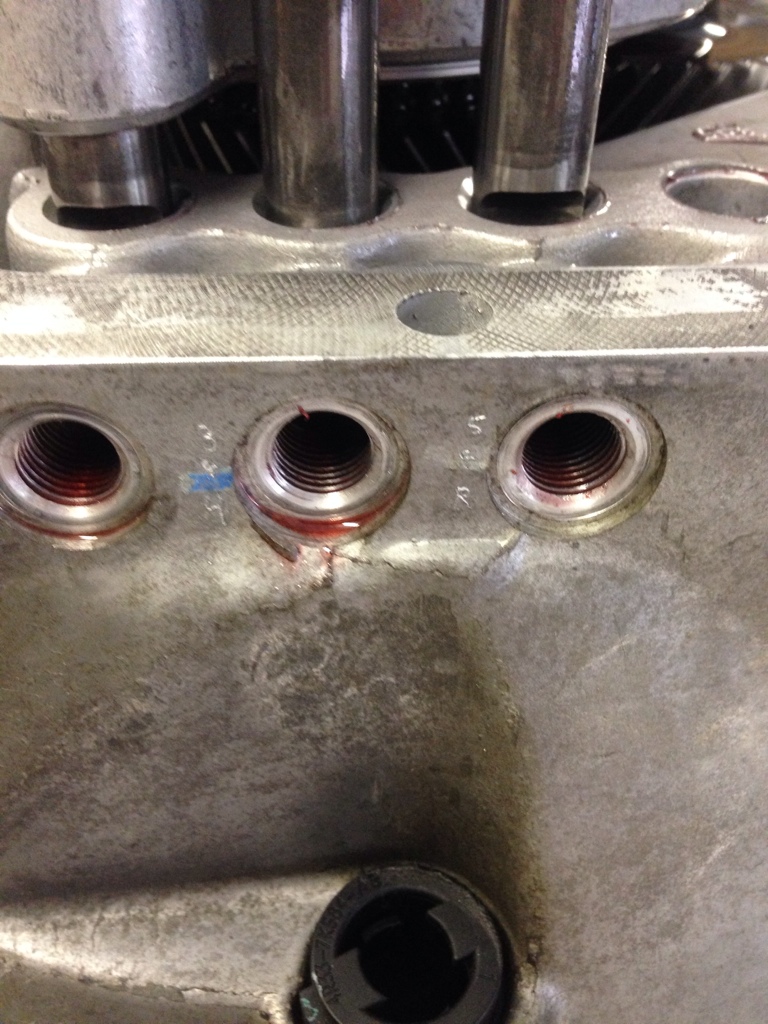

Now remove two 13mm bolts that hold the interlock plate on and slide the plate up, there will be 3 lock pins, (2) visible and (1) in the middle inside of the 3rd & 4th shift rail as pictured, remove those as well.

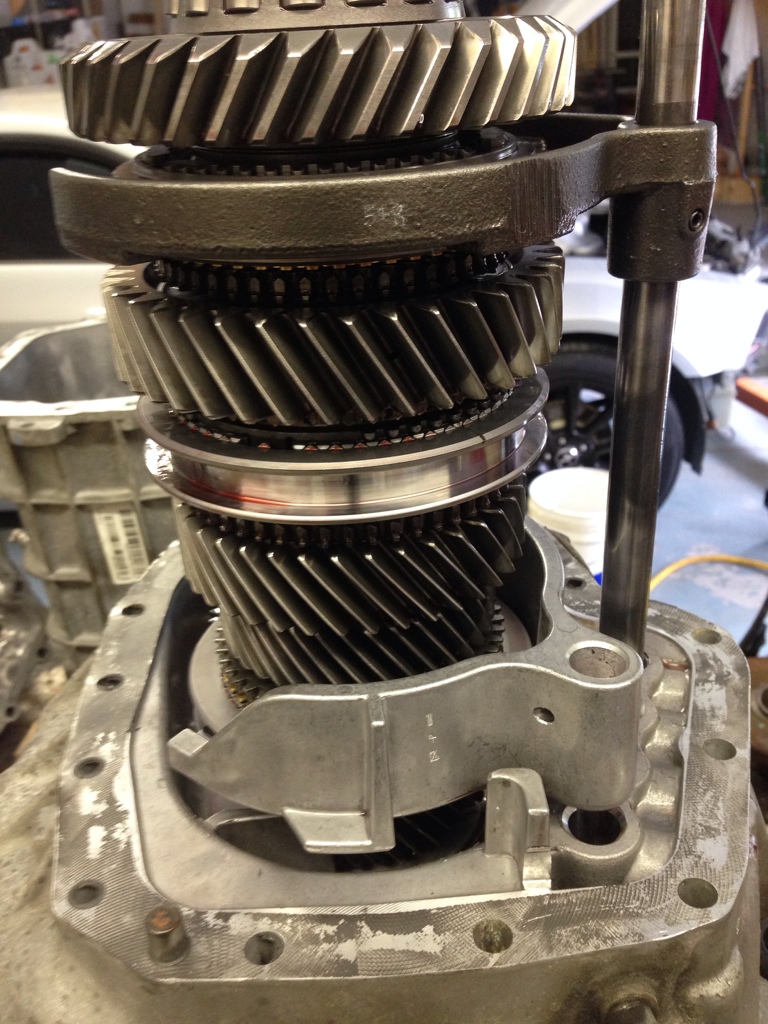

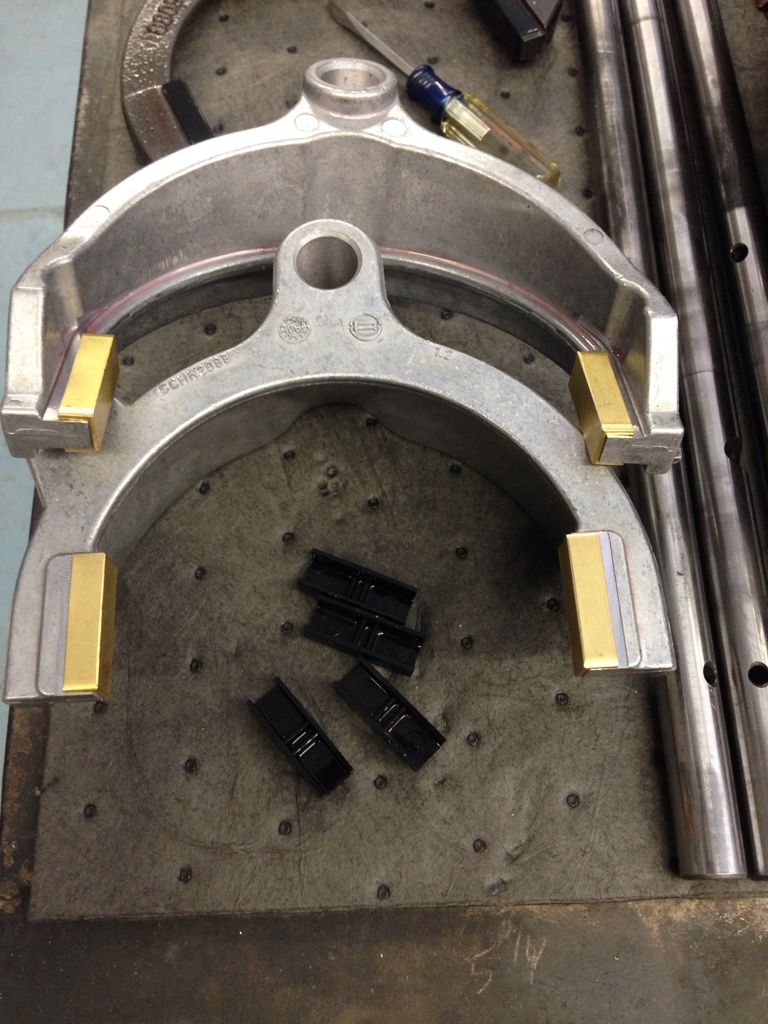

That completes the tail end disassembly, you can now lay the transmission down, loosen (14) 13mm bolts, keep (2) on opposite sides in and snug, remove the other (12).

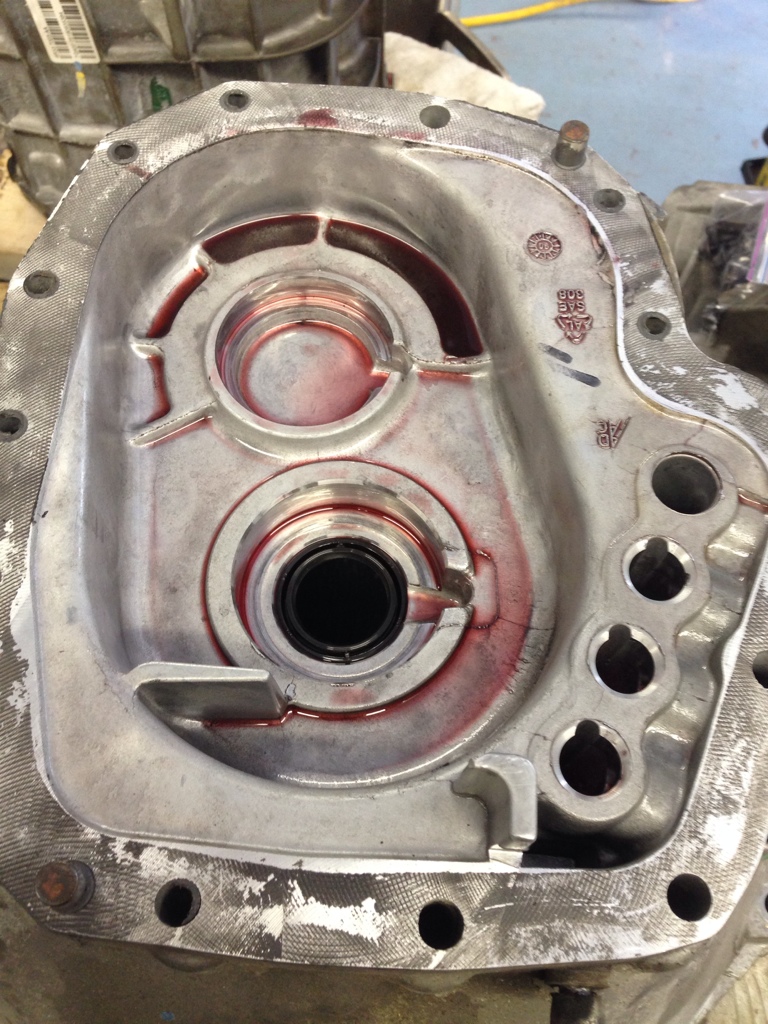

Now stand the transmission bell housing side down (on some tall blocks, I used 4x4) and reach under neath and remove the last (2) bolts, now pry the case carefully and slide it up, be sure to hold the bearing cone while lifting up, it's a struggle to do it by yourself so get someone to help if you can. After it's free of the cluster gear you can slide it up and off!

That is where I left off, I will pick back up when I get a torx plus t45 socket/bit.