I'm not reading hundreds of words to tell me how which tires sizes I should run.

Aspect ratio most definitely has a lot to do with how well a tire will fit onto a wheel.

It's part of the reason a 305/40 or a 305/45 "fits just fine" on a 18x9.5 wheel, like so many SVT guys do (and myself with my 305/40/18 drag radials on my 18x9.5 wheels).

Now if you try to fit a 305/30/18 onto that same 18x9.5 wheel, you'll quickly fin that sidewall bulging, the tread patch oval not flat against the ground, and if you do that shit on a front tire and actually corner, you'll probably even end up damaging the tire or the wheel or both.

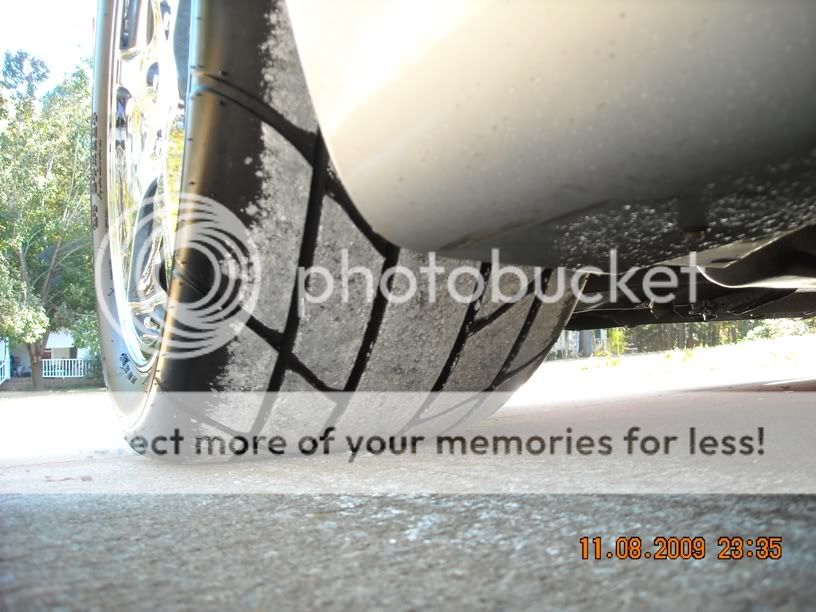

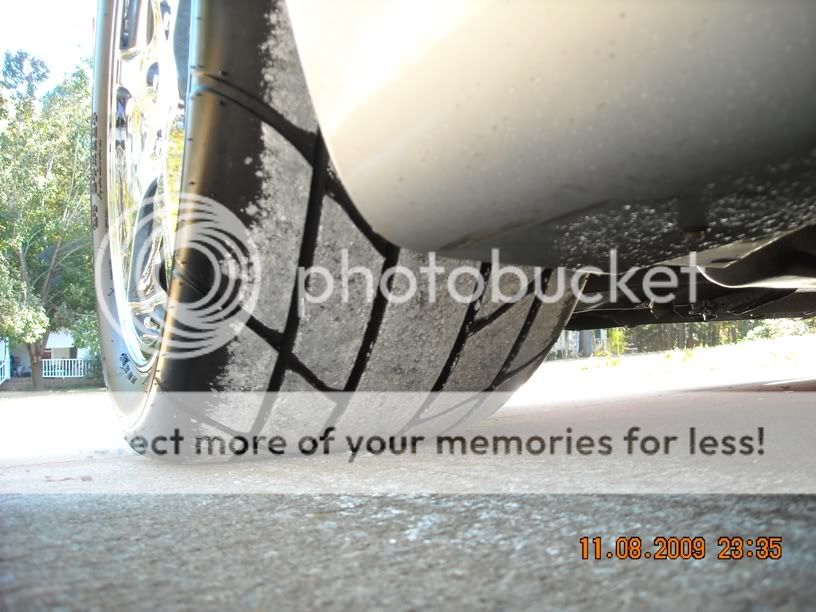

This is a 305/35/18 on a 18x9.5, can easily see how much tread is not hitting the ground, at the outer parts of the contact patch, because the wheel is too narrow:

That's gonna be even worse when the shorter 305/30/18 sidewall "pulls up" on the edges of the tread/contact patch.

But a taller sidewall allows the tire to relax and it doesn't affect the contact patch reduction as much.

Aspect ratio most definitely has a lot to do with how well a tire will fit onto a wheel.

It's part of the reason a 305/40 or a 305/45 "fits just fine" on a 18x9.5 wheel, like so many SVT guys do (and myself with my 305/40/18 drag radials on my 18x9.5 wheels).

Now if you try to fit a 305/30/18 onto that same 18x9.5 wheel, you'll quickly fin that sidewall bulging, the tread patch oval not flat against the ground, and if you do that shit on a front tire and actually corner, you'll probably even end up damaging the tire or the wheel or both.

This is a 305/35/18 on a 18x9.5, can easily see how much tread is not hitting the ground, at the outer parts of the contact patch, because the wheel is too narrow:

That's gonna be even worse when the shorter 305/30/18 sidewall "pulls up" on the edges of the tread/contact patch.

But a taller sidewall allows the tire to relax and it doesn't affect the contact patch reduction as much.