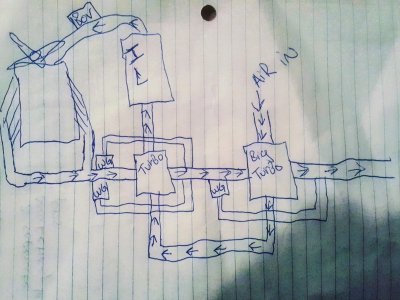

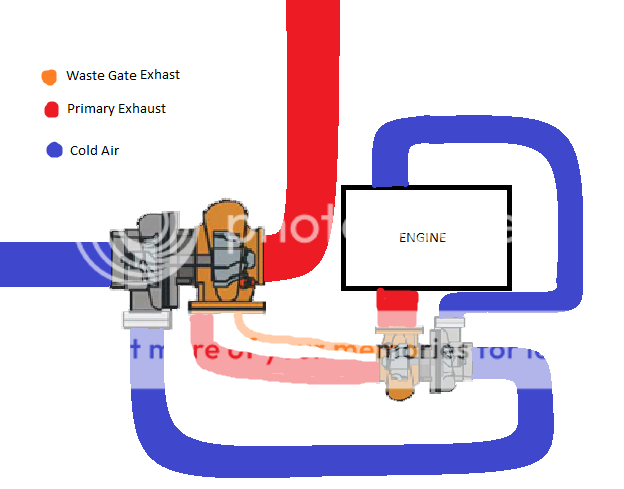

I stand corrected, this diagram is accurate with some provisions of hot side routing. The LP turbo *is* the larger turbo and the HP turbo is the smaller turbo. The smaller turbo spools fast and draws air through the LP turbo and boosts it directly into the engine, doing what turbos do best and recycling that quick spooled boosted exhaust through itself as well as feeding the hot side of the LP turbo. If sized correctly, the combination of drawing air through the LP turbo impeller as well as being fed the downpipe of the HP turbo will spin up the larger LP turbo much faster than it would otherwise on its own.

As for pipe routing, honestly other than looking like a maze of pipe, there really isn't all that much extra length in this type of setup. It just looks over-engineered. Turbos really aren't my thing, I usually differ to Jeremy's words of wisdom in the matter, but one principal has always held true over all FI so far. The more CFM a mechanical device can push, the less pressure is needed to push it. Boost is a measure of resistance the air encounters along its path. A tiny turbo on a WRX can make 20-30 psi and push nowhere near the CFM a larger turbo at half that pressure will. That's why sizing is so critical. In this instance, the HP turbo will need an inlet sized to flow what the LP turbo is going to throw at it in CFM rating, as well as being able to spin like a sonovabitch, cuz that turbo is going to be going like a bat out of hell when the LP turbo starts chugging.

Cooling the air charge is another matter, but this isn't exactly unexplored territory, I'm sure any reputable turbo outfit can point the OP in the direction of the IC setup he would need. Beyond that, there's always Meth and E85. For how much boost the engine itself will be able to withstand, I've ridden in a drag cobra pushing 42psi through 4v "C" heads, so physically the engine can hold it. I'm just not sure if the 3v can flow it.

I get where all the realists are coming from with the traditional suggestions of single and twin turbo setups, but as I'm reading from the OP, he really doesn't want to follow a traditional setup and obviously accepts the consequences regarding budget and the struggle of the build. Personally, I'm fascinated to see him build it and if it holds up to theory, and how far he can really push it before failure or his butthole puckers and decides where good enough really is.