OK, was wondering when this kid's video would end up here - it's been making rounds on the interwebs for days. We talked to Forgestar about this video the morning it was posted and I will comment with some things that aren't being said by the S2000 driver as well as some things that are obvious in his video, if you know what to look for.

1. This S2000 driver is

hitting every curb on that track. I've driven Buttonwillow and those are not "little curbs", either. Curb crashers break all wheels.

2. This car looks too softly sprung and was BOTTOMING THE SUSPENSION on every curb he hit

(edit: if you read his S2000 forum posts, he has apparently blown out one set of KW coilovers already). Jason and I have watched the video several times and that setup is a recipe for disaster - no matter the wheel maker.

3. This set of Forgestars was THREE years old. They weren't just used a handful of times, either. He clearly misrepresented that in his video.

4. All four wheels had cracks in the spokes the driver ignored for a long time. Old cracks which propagated over many race weekends. And they made LOUD noises for a good while before they let go - you can hear them in the video. The close-up pics revealed the cracks had been there for months and the raw aluminum had started to corrode inside the cracks. Anyone that would have done

even a simple HPDE inspection would have seen these cracks long before the first wheel let go. I would be embarrassed if I had posted that... this was an "ignorant to HPDE inspections" error in every way.

5. I can show you pictures of broken wheels from EVERY manufacturer you can think of across the cost spectrum. Enkei, CCW, HRE, BBS, Forgeline, D-Force, etc. There's always somebody that can break anything, and no wheel has an infinite lifespan.

Our advice is simple:

1. Don't let some kid with a slick video posted on the internet trick you into believing something we all know to not be true - he clearly had an agenda, and it worked. Forgestar gave him his wheel costs back + the costs for his ball joint. They shouldn't have, because now this entitled, ignorant kid probably thinks he was "right" to post this video. He was not - this was poor maintenance and track ignorance

exemplified. Glorified, even.

This is the first wheel fatigue failure I've seen in 6+ years of Forgestar wheels being used in motorsports, but it was bound to happen - especially as abused as this S2000 was. After looking at the pictures and his video I'm convinced this catastrophic wheel failure could have

easily been avoided if the driver ever even glanced at his wheels before a track weekend.

Use your eyes.

2. We here at Vorshlag have vetted these wheels on both light and heavy cars with much higher levels of mechanical and aero grip. I've had one set from our Mustang for 4 years and the rears were still in service when I sold the car. I've never cracked a single Forgestar wheel in 4+ years of racing on and selling them.

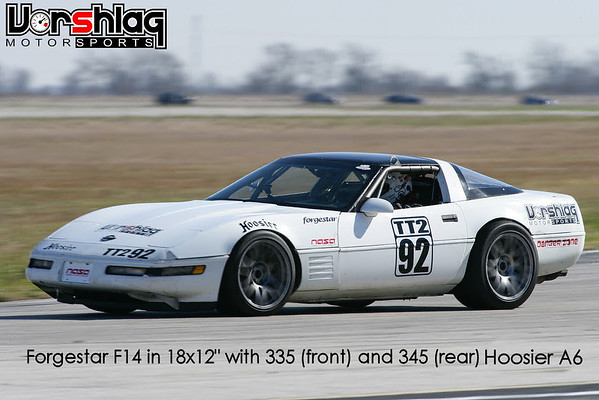

We ordered our first set of Forgestars (above) in early 2012 - and they are still in service. The same fronts are in my lobby right now!

3. Wheels are consumable items, just like everything else on a race car. After so many cycles things reach an endurance limit (look it up) and have to be "cycled out". This is why I never buy used wheels - how many thousands of laps have they already been through before they were sold second hand to you? Always

always inspect your wheels (and suspension, and brakes, and fluids, and etc) and look for fatigue cracks on the insides of the spokes (hub side) before a track weekend.

4. We have a small percentage of customers that can break anything. These guys tend to bend or crack wheels of all brands, given enough time. Some people

can break an anvil with a feather! Don't be "that guy". If all you aren't even looking at lap times: don't drive 11/10ths, stay off the damned curbs and FFS

keep it on the track. Don't be like this asshat below...

5. Don't set up your suspension so it bottoms out. That WILL cause catastrophic failure eventually, no matter the brand of wheel. If not a wheel, then a hub, spindle, strut/damper, or chassis.

6. If you are ignorant about how to

fix your setup and the suspension

still bottoms out easily, don't run over every curb on track!

7. When you hear new loud noises while on track - stop, come in, and find out what is causing them. If you hear something unusual, something is most likely wrong and needs to be addressed, not ignored.

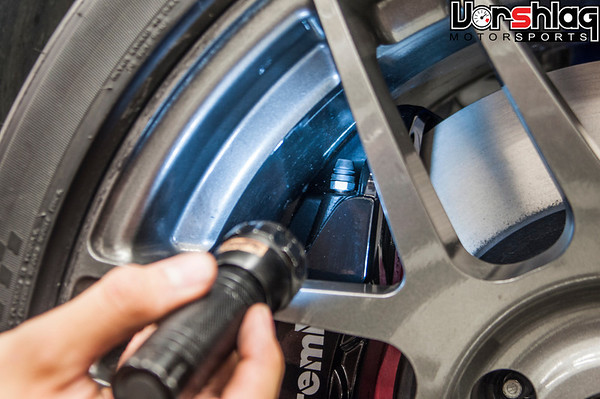

8. Have your car checked out

thoroughly by an expert (which could even be

yourself) before any HPDE, time trial, wheel to wheel race, etc. These are just some of the things shops like our's will find during a pre-track inspection - small cracks that can quickly turn into a wheel failure. Remove and wash your track wheels after every event and then

look at the BACK SIDE of the spokes.

We have one customer who comes in for an HPDE inspection after every 2 track events he does. Guy has been running this Boss302

hard on track for years and has never suffered a single breakdown at any track event. We have spotted worn or otherwise failing things long before they crapped out on him, and he appreciates that - especially when his buddies have failure after failure on track. And while pre-track inspections won't catch

everything, they would have easily caught these wheel cracks on all of this S2000's wheels

(edit: which were likely caused by a 100+ mph "off" he had at a different track a few weeks earlier - see the video below).

And while I often tout "you always get what you pay for", and this applies to Forgestar and any other wheel makers, you won't find a better value for your dollar than their custom wheels. The

same techniques Forgestar uses to make their 1-piece wheels go into all modern flow formed/rotary forged 1-piece wheels - SSR, Enkei, D-Force, HRE, and on and on. Forgestar has their wheels

tested by an outside firm to check Dynamic cornering fatigue, Dynamic radial fatigue and Impact testing using standards published by SAE (J2530) and JWL VIA.

There are about 4 ways to make wheels but flow formed is the most cost effective way to make a light

and strong wheel. Forgestar has a unique business model that allows them to bring in the semi-finished blanks and then final machine the backspacing, hub bore, lug holes, and finish them to the customer's specs. Every set we order is custom made to order, and the only real downside is time... it used to take 3-6 weeks to get a set made and lately (during peak racing season / post tax refund season) it is closer to 6-8 weeks. Popularity of this brand is the reason.

I have used Forgestars on many of my own street cars and race cars in 17" and 18" and even on my shop truck (below) in 20". I can vouch for their strength and quality first hand. Just like we do with all product lines we sell - we test them first. We don't want to sell a janky product we cannot trust. This S2000 was on 17x10" F14 wheels and Bridgestone RE71R street tires and failed all 4, yet my 3350 pound BMW on the

exact same 17x10" F14s is running Hoosiers and hasn't had a single issue in many weekends of abuse.

Truck Norris gets driven hard and has been on Forgestars for 3 years

We've run 18x10, 18x11, and 18x12 F14 and CF5 wheels on countless cars, including many of our own. In 4 years and 2 crashes we've bent 3 Forgestar wheels - one rear when my wife went over a 12" tall curb sideways at 90 mph (crash) and two fronts when I had a 150+ mph crash at Road Atlanta (where I crushed a vertebrae). These wheels deformed

exactly as they should have in a crash, and each one absorbed energy in the crash. I drove back to the pits at RA on the bent front wheels and they even never air, and didn't show a single crack.

I see so many people using 30-35+ pound, cheap, cast "replica" wheels and yet nobody bats an eye around here. Heavy wheels are bad for the dampers, bad for braking, bad for acceleration - just the wrong choice for a performance car. If you are checking lap times, you deserve better than $150/corner gravity cast boat anchors. The next step up for wheels, that actually fit an S197 in real sizes (10-12" widths), is Forgestar. Beyond their cost level ($350-360/wheel) you can move to CCW Monoblocks ($900/corner) or Forgeline custom 1-piece and 3-piece wheels ($1500/corner) and beyond. They aren't any stronger, but might be 1-1.5 pounds lighter (1-piece).

I'm excited that customizable, affordable, and wide 1-piece wheels even

exist for the gear head crowd. 5 years ago our only choice for wide wheels on these cars was 3-piece or custom monoblocks, all of which cost crazy money. With the Forgestar prices folks can afford to buy 2 sets of wheels for less than the cost of one set of the next cheapest custom wheel in these widths - and many people often do. We always had 2 sets of wheels and tires with us for our TT3 car - a set of scrubs for testing or setting grid qualifying times, and a set of sticker tires "just in case". Makes your good tires last longer, and ultimately the tires we ran (Hoosier A6/A7) cost more each than the wheels. Which is crazy, yet we put dozens of sets of Hoosiers on each set of Forgestars we have owned.

That's all I have. It just bugs me that so many people are willing to jump on this S2000 driver's defense, like he got screwed with his 3+ year old wheels that he curb jumped on the bumpstops the whole time. Ignored old cracks, ignoring weird wheel noises, ignoring a poorly setup suspension, ignoring bad driving habits. In this short-attention-span time of no accountability, so many were quick to jump on the hater train.

Meanwhile we keep getting more and more Forgestar wheel orders, with 30+ sets in the pipeline right now. I won't use anything else on my own cars, because nothing else can touch their price/performance quotient in custom sized wheels. Except there is a new wheel they make that goes even farther...

The M14. I'll talk about this in a separate announcement, but this 2-piece wheel is based on the 18" F14 and has a bolt-on outer rim. Its not a new technique (multi-piece wheels) but it does give us some options beyond 18x12"... all the way to 18x14.5" in 1/2" width increments. And for only $575/wheel. More about that soon - one of our members on this very forum here already ordered a pair in 18x13" for his car...

Cheers,