Should be a techy thread so I will put this here as a follow up to the install of the new billet turbo thread.

http://www.s197forum.com/forum/showthread.php?t=43665&highlight=turbo

Got out to the dyno today at Mid Atlantic Performance in Richmond and let Mike Rousch work his magic. Had to get the tune tweaked for the new turbo and the driveability issues fixed.(last time i was on the dyno i had bad 02 sensors.)

Old turbo was Precsion cast wheel 67mm. And the new turbo is the same 67mm size with a billet wheel.

So, first off backed off the boost controller to get the boost back down(at the same boost controller setting the new turbo was making 2-3 more psi) New street tune at 11.6 psi 550rwhp 510rwtq only pulled to 6000rpms would have made a little more power if we spun it higher, but no need, a/f was good and we wanted to turn up the boost.

(old turbo made 563rwhp 516rwtq at 12.1 psi reving to 6500, so similar numbers)

Next were the shocking results!!! Bumped it up a few psi with the boost controller and at 14.6 psi made basicly the same power numbers up top at the exact same boost level as the old turbo.(old turbo 603rwhp , new turbo 605 rwhp) So we overlayed the old cast turbo pull and the new billet turbo pull and we were shocked! At 3800 rpms the billet turbo was up 130rwhp and 141rwtq! Huge gain in midrange and spool! From the start of the pull from 2,000 rpms the billet turbo is already up 30hp/tq and just climbs from there!

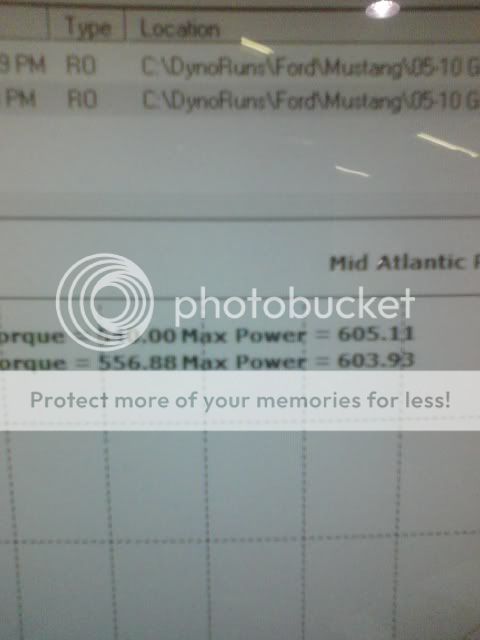

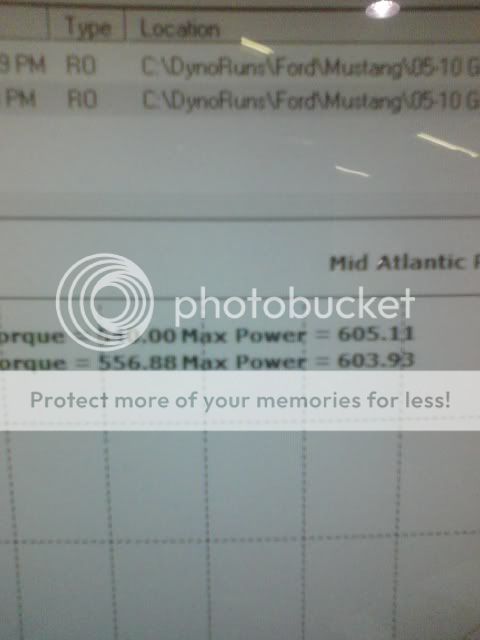

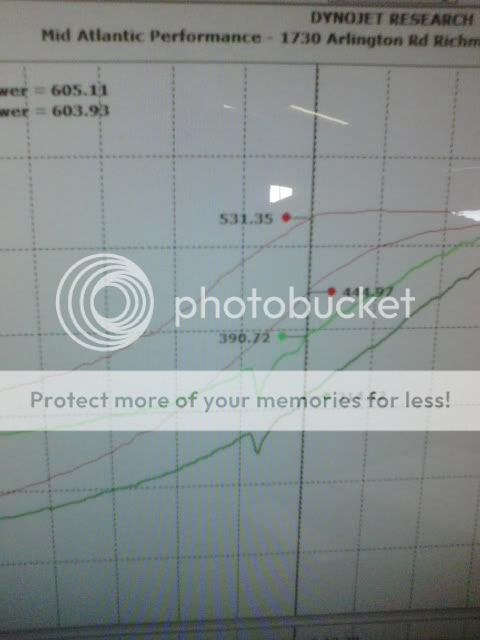

Old vs new peak numbers (603 is old, 605 is new)

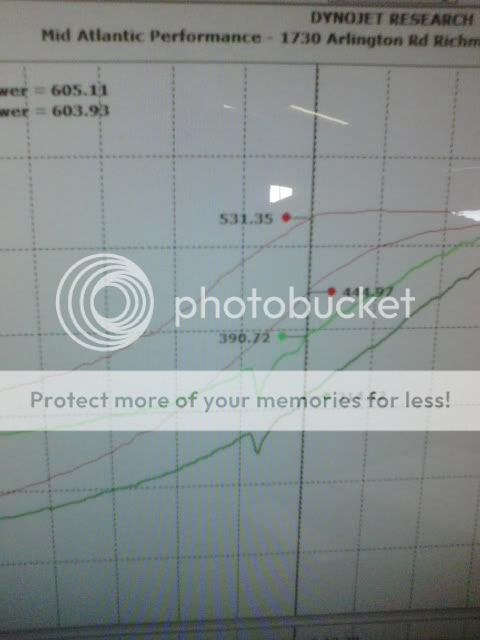

Old turbo 14.6psi pull in green, new turbo 14.6 psi pull in red. (from 5,000 rpms and up the graphs even out, but from 2,000 rpms to 5,000 rpms the billet turbo is murdering the cast turbo in power and torque output!)

At 3800 rpms the billet turbo was up 130rwhp and 141rwtq!

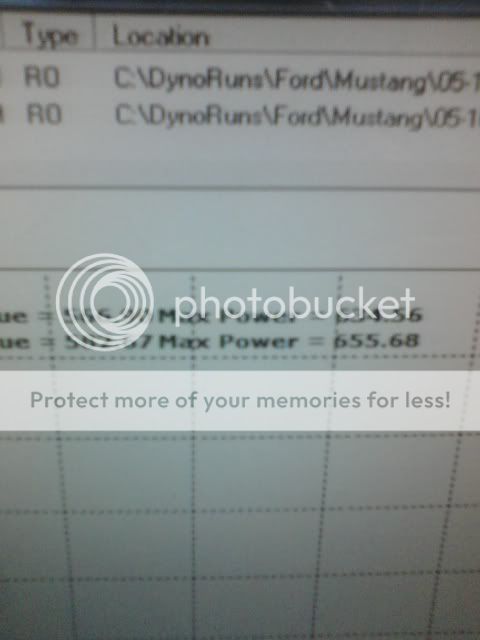

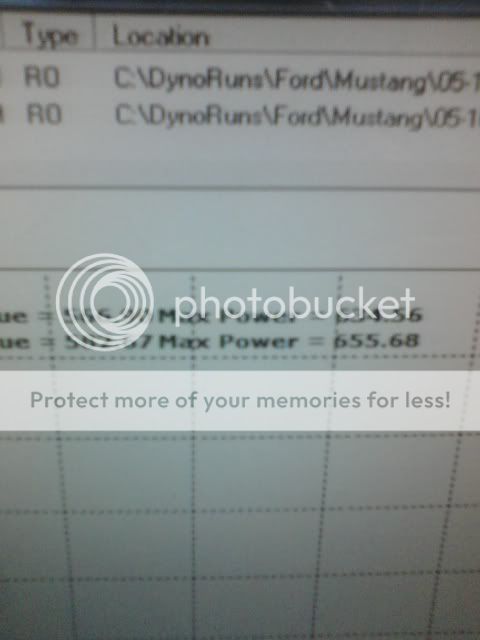

Badass!, why not crank it up a lil more? lol added another 10% to the boost controller duty cycle and made 16 psi, final numbers 655rwhp 582rwtq!

Called it a day there! Thats about the most boost/power I want to run on pump gas (93 octane.)

http://www.s197forum.com/forum/showthread.php?t=43665&highlight=turbo

Got out to the dyno today at Mid Atlantic Performance in Richmond and let Mike Rousch work his magic. Had to get the tune tweaked for the new turbo and the driveability issues fixed.(last time i was on the dyno i had bad 02 sensors.)

Old turbo was Precsion cast wheel 67mm. And the new turbo is the same 67mm size with a billet wheel.

So, first off backed off the boost controller to get the boost back down(at the same boost controller setting the new turbo was making 2-3 more psi) New street tune at 11.6 psi 550rwhp 510rwtq only pulled to 6000rpms would have made a little more power if we spun it higher, but no need, a/f was good and we wanted to turn up the boost.

(old turbo made 563rwhp 516rwtq at 12.1 psi reving to 6500, so similar numbers)

Next were the shocking results!!! Bumped it up a few psi with the boost controller and at 14.6 psi made basicly the same power numbers up top at the exact same boost level as the old turbo.(old turbo 603rwhp , new turbo 605 rwhp) So we overlayed the old cast turbo pull and the new billet turbo pull and we were shocked! At 3800 rpms the billet turbo was up 130rwhp and 141rwtq! Huge gain in midrange and spool! From the start of the pull from 2,000 rpms the billet turbo is already up 30hp/tq and just climbs from there!

Old vs new peak numbers (603 is old, 605 is new)

Old turbo 14.6psi pull in green, new turbo 14.6 psi pull in red. (from 5,000 rpms and up the graphs even out, but from 2,000 rpms to 5,000 rpms the billet turbo is murdering the cast turbo in power and torque output!)

At 3800 rpms the billet turbo was up 130rwhp and 141rwtq!

Badass!, why not crank it up a lil more? lol added another 10% to the boost controller duty cycle and made 16 psi, final numbers 655rwhp 582rwtq!

Called it a day there! Thats about the most boost/power I want to run on pump gas (93 octane.)

Last edited: