Kind of the point.so if u get this product u dont have to weld ur tubes right??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

If you Drag Race, PLEASE weld your axle tubes.

- Thread starter BMR Tech

- Start date

SSPSTANGBANGER

LSx Slayer

Is UPR trolling this thread for spy photos yet?

Sent from my iPhone 5S

Sent from my iPhone 5S

mattadams6552

forum member

Im ready to buy!

Norm Peterson

corner barstool sitter

Until the mold release agent gets worn off new tires, they don't have as much traction as they eventually will.

More information would help, like axle gears, is it a manual transmission and it's hopping on a brutal upshift, etc.

Norm

More information would help, like axle gears, is it a manual transmission and it's hopping on a brutal upshift, etc.

Norm

Until the mold release agent gets worn off new tires, they don't have as much traction as they eventually will.

More information would help, like axle gears, is it a manual transmission and it's hopping on a brutal upshift, etc.

Norm

Norm... Anytime I let off the gas or just press on the gas to maintain.... I have 3.73 gears and manual transmission... When I first got the tires, no hop... Until the next morning I noticed my radar detector bouncing and I'm shaking. at lower speeds it's there but not as bad, but at 80 miles per hour it's annoying.

Norm Peterson

corner barstool sitter

Flatspotted or otherwise out-of-round tires?

Norm

Norm

We changed our design from the drawing up above. Sigh...

It just invited/brought on too much complication, and the possibility of too many user-end errors that would result in me doing "tech" all day long, everyday, just for the axle brace.

Our only other option is to make one that mounts outward at the LCA mounts, like the others do. Ours will be a step above the rest though, I promise.

It just invited/brought on too much complication, and the possibility of too many user-end errors that would result in me doing "tech" all day long, everyday, just for the axle brace.

Our only other option is to make one that mounts outward at the LCA mounts, like the others do. Ours will be a step above the rest though, I promise.

What's happening with this?

Is it just part of the Watts link setup?

It "was" going to be either the Watts, or the Brace....you have to choose which one you run.

Now....I believe we are going to be able to make it user friendly for anyone.

Ugh, can you make a version for people who are not retards? LolWe changed our design from the drawing up above. Sigh...

It just invited/brought on too much complication, and the possibility of too many user-end errors that would result in me doing "tech" all day long, everyday, just for the axle brace.

Our only other option is to make one that mounts outward at the LCA mounts, like the others do. Ours will be a step above the rest though, I promise.

LAStang1234

----------DSL----------

Ugh, can you make a version for people who are not retards? Lol

LOL! This!!

T-Neck

Here for the Gangbang

Subbed for the axle brace! Anything? I'd really hate to order a CHE and leave my relo brackets in the bag and just not run any...i'm lowered almost 2 inches, i'd really like to bolt them in WITHOUT tearing my tubes apart.

I wasn't able to wait any longer for the new BMR brace, so I went ahead and solved the axle rotation issue at least by improving on the bolt/pinning method described earlier in the thread.

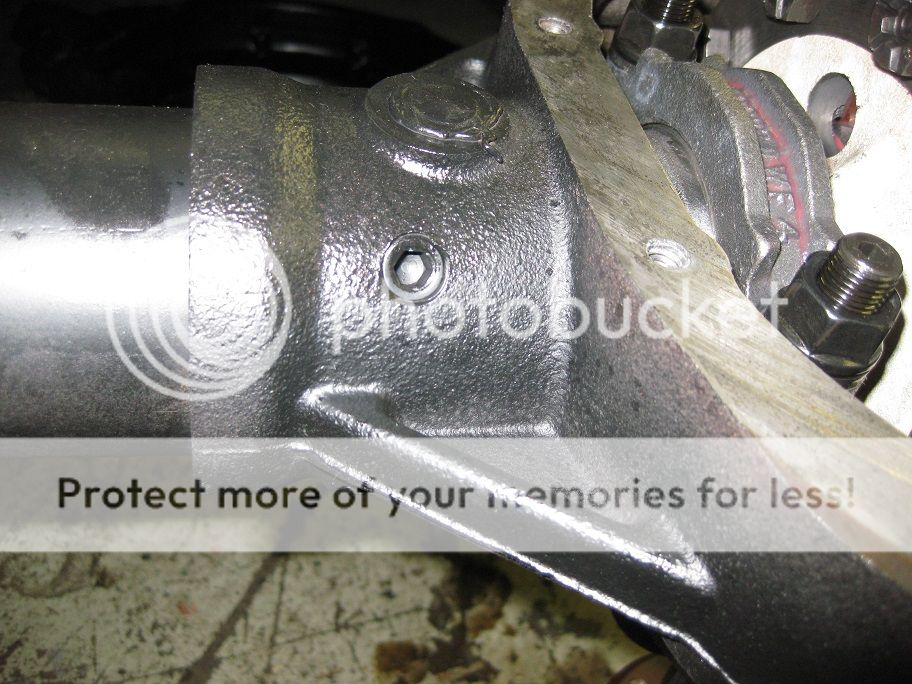

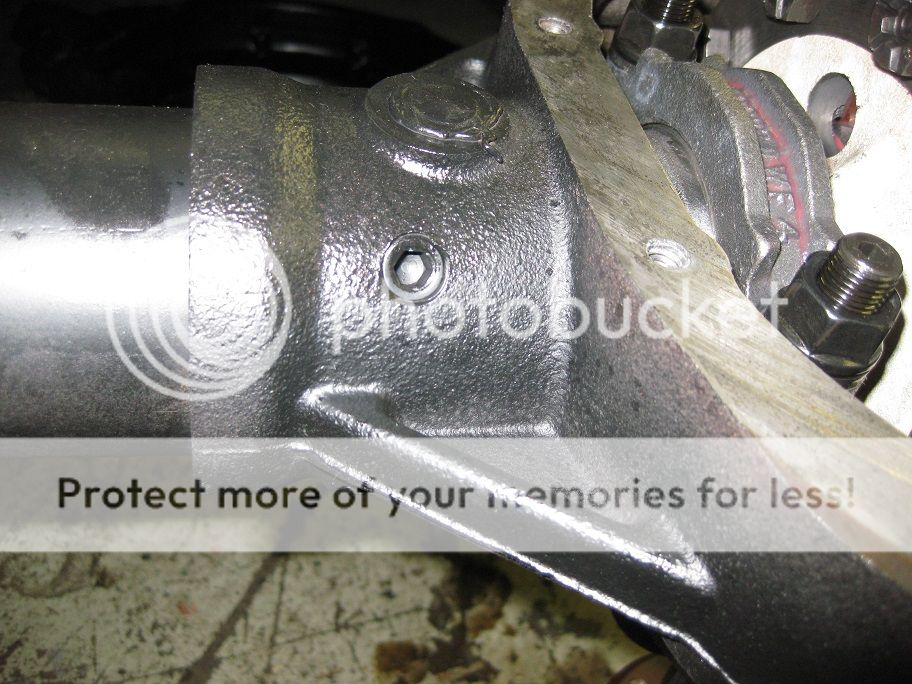

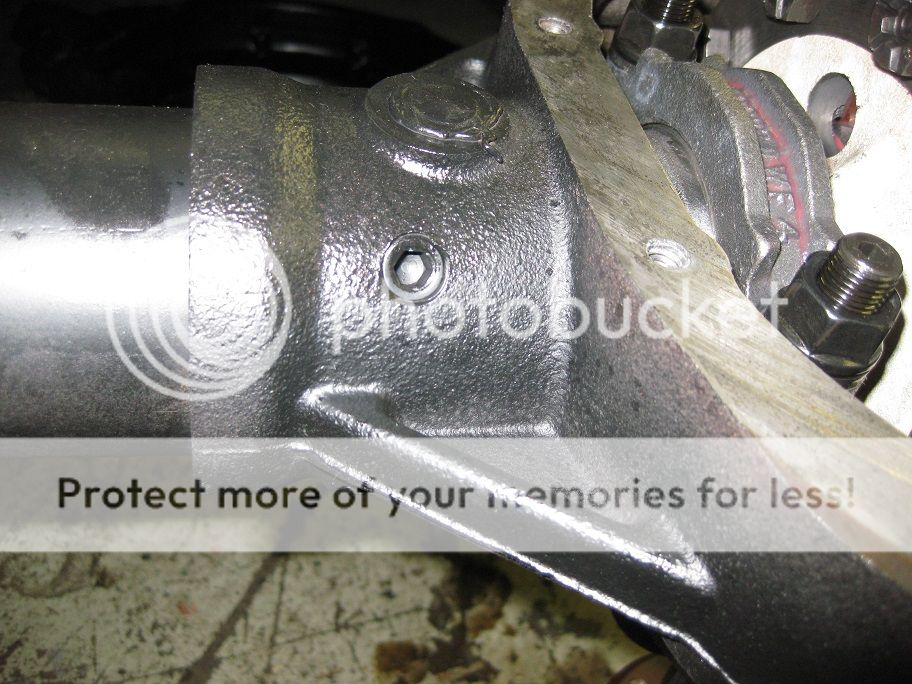

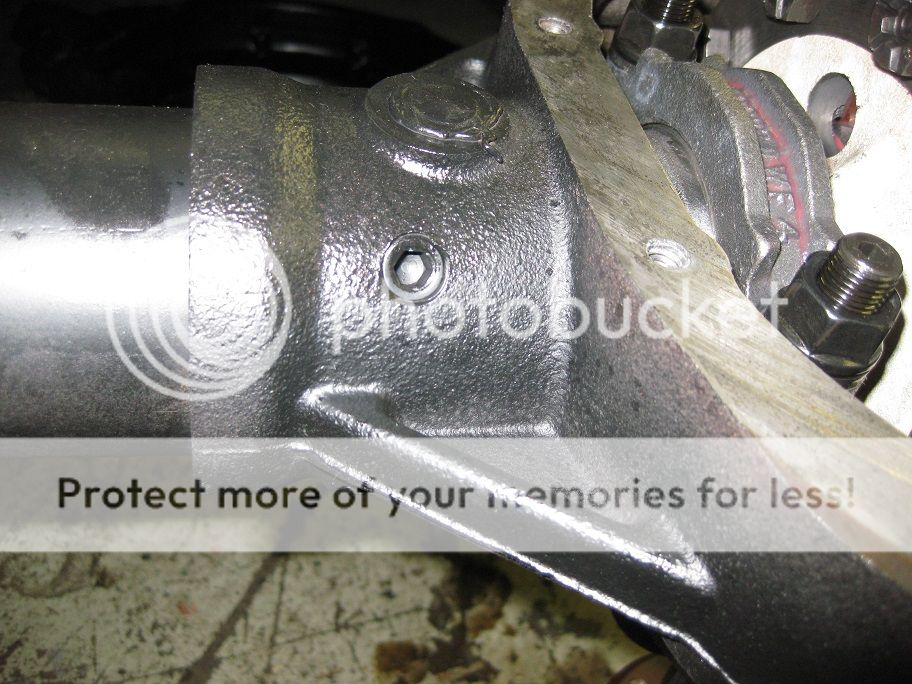

I used 3 1/4" Unbrako ASTM-A574 Dry Seal NPT plugs per tube. These are stronger than Gr. 8 hardware, sit flush with both the tube OD and ID, are self retaining, and won't leak.

Pretty happy with the appearance of the results. Probably a decent option for those that don't have the ability or confidence in the welding.

I used 3 1/4" Unbrako ASTM-A574 Dry Seal NPT plugs per tube. These are stronger than Gr. 8 hardware, sit flush with both the tube OD and ID, are self retaining, and won't leak.

Pretty happy with the appearance of the results. Probably a decent option for those that don't have the ability or confidence in the welding.

T-Neck

Here for the Gangbang

I wasn't able to wait any longer for the new BMR brace, so I went ahead and solved the axle rotation issue at least by improving on the bolt/pinning method described earlier in the thread.

I used 3 1/4" Unbrako ASTM-A574 Dry Seal NPT plugs per tube. These are stronger than Gr. 8 hardware, sit flush with both the tube OD and ID, are self retaining, and won't leak.

Pretty happy with the appearance of the results. Probably a decent option for those that don't have the ability or confidence in the welding.

looks good, I'm assuming you took apart your axle.

I wasn't able to wait any longer for the new BMR brace, so I went ahead and solved the axle rotation issue at least by improving on the bolt/pinning method described earlier in the thread.

I used 3 1/4" Unbrako ASTM-A574 Dry Seal NPT plugs per tube. These are stronger than Gr. 8 hardware, sit flush with both the tube OD and ID, are self retaining, and won't leak.

Pretty happy with the appearance of the results. Probably a decent option for those that don't have the ability or confidence in the welding.

Where is the muhfuckin 'how to' man!?

So that one plug is going to be what's needed?

Similar threads

- Replies

- 65

- Views

- 6K

- Replies

- 4

- Views

- 5K

- Replies

- 11

- Views

- 2K

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details