anyone making use of data acquisition at the track to further tune their car?

- autometer ultimate memory tach

- rpm performance data logger (basic)

- racepak sportsman

- etc...

the following is an excerpt from a manual trans racing forum I've been watching:

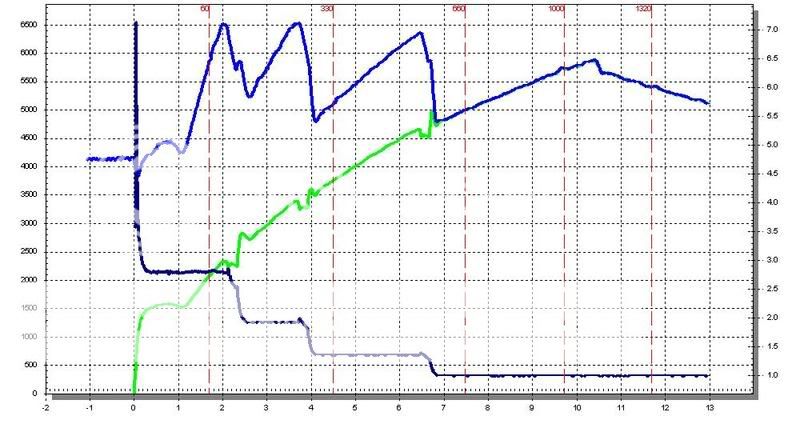

[FONT=Verdana, Arial, Helvetica]example of the rpm data from an Ultimate tach

[/FONT]

[FONT=Verdana, Arial, Helvetica]Blue is motor RPM, Green is driveshaft RPM, and the other is some type of weird composite of both RPM's that I have yet to understand (and usually turn off).

Note that the tach records for 2 seconds before the launch and shows the 2 step holding RPM (4200.) When launched the car initially hooks, bogs, hooks and bogs again before finally accelerating to the top of first gear. Video showed that both wheels hit hard and wheel hopped. You can see the shift RPM's and the effect on the driveshaft speed, plus how far the motor drops off during shifts. The car is in first gear until after the 60' mark. Once the car is in 4th gear the engine and driveshaft RPM's are the same. You can also see that this run was aborted before the traps. There is more info to be gained by studying this graph, but that is about as much as this novice has ID'ed while studying it.

Info markers shown on the graph (ie 60', 330', etc) comes from manually entering data into the graphs database from the timeslip.

[/FONT][FONT=Verdana, Arial, Helvetica]At first blush the cost seems prohibitive, but most would think nothing of spending $500+ on a 1pc drive shaft - and I think the data above would be more helpful in the long run. I'm interested in hearing any experiences and pros/cons for any particular system.

thanks, and Happy New Year!

[/FONT]

- autometer ultimate memory tach

- rpm performance data logger (basic)

- racepak sportsman

- etc...

the following is an excerpt from a manual trans racing forum I've been watching:

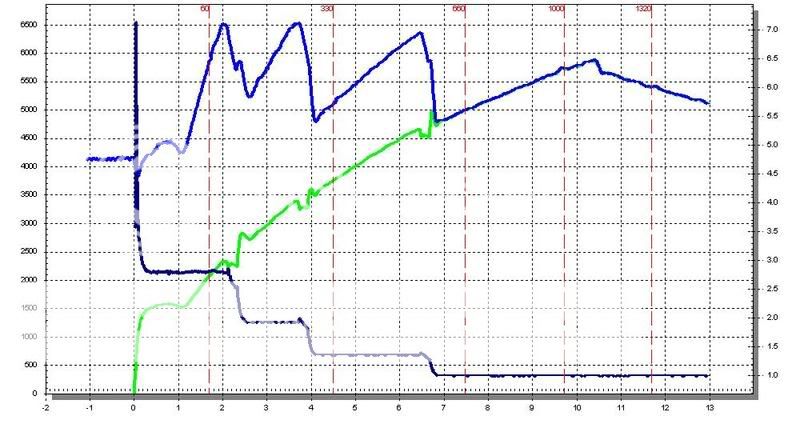

[FONT=Verdana, Arial, Helvetica]example of the rpm data from an Ultimate tach

[/FONT]

[FONT=Verdana, Arial, Helvetica]Blue is motor RPM, Green is driveshaft RPM, and the other is some type of weird composite of both RPM's that I have yet to understand (and usually turn off).

Note that the tach records for 2 seconds before the launch and shows the 2 step holding RPM (4200.) When launched the car initially hooks, bogs, hooks and bogs again before finally accelerating to the top of first gear. Video showed that both wheels hit hard and wheel hopped. You can see the shift RPM's and the effect on the driveshaft speed, plus how far the motor drops off during shifts. The car is in first gear until after the 60' mark. Once the car is in 4th gear the engine and driveshaft RPM's are the same. You can also see that this run was aborted before the traps. There is more info to be gained by studying this graph, but that is about as much as this novice has ID'ed while studying it.

Info markers shown on the graph (ie 60', 330', etc) comes from manually entering data into the graphs database from the timeslip.

[/FONT][FONT=Verdana, Arial, Helvetica]At first blush the cost seems prohibitive, but most would think nothing of spending $500+ on a 1pc drive shaft - and I think the data above would be more helpful in the long run. I'm interested in hearing any experiences and pros/cons for any particular system.

thanks, and Happy New Year!

[/FONT]