Jack Wallace

Junior Member

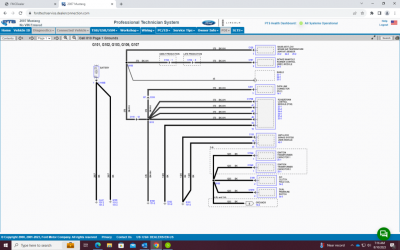

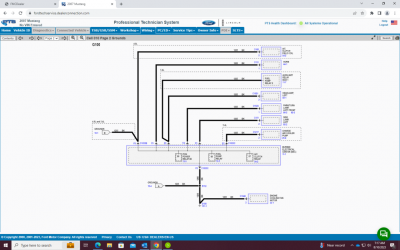

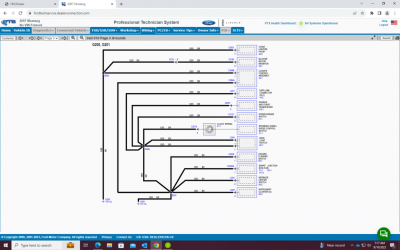

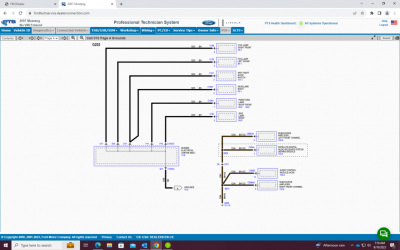

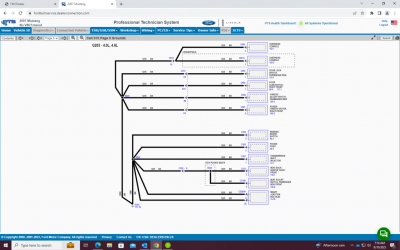

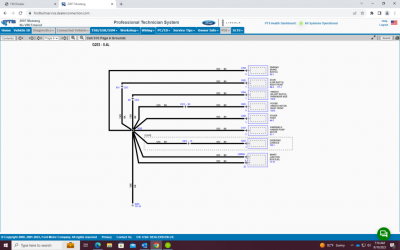

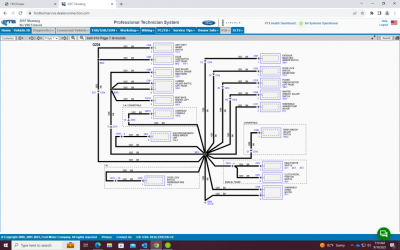

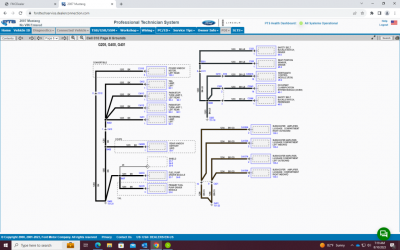

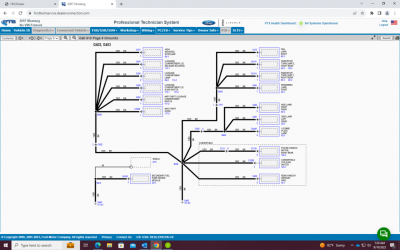

Hey guys! Currently in the process of restoring a 2007 Mustang GT. I’m redoing a lot of the factory wiring as some of it is damaged or just looks dingy and I’ve got a couple questions about the grounds. I’ve relocated the battery to the trunk, so I will be relocating all of the grounds (all 2, lol) that originally came off of the negative battery terminal when it was in the engine bay (don’t worry, I have grounded the negative terminal on the battery to a good location in the trunk). My current plan is to ground G106 (starter) and G107 (actually not sure where this goes, please tell me if you know) to the same location on either the body or frame (using 2 4AWG wires connected at the same location). I also need to figure out exactly where G102 and G103 were originally grounded so I can put them back in the right spot (I believe they may ground to the same location?). Will I have any issues doing this? If someone could tell me the exact locations of G102, G103, G106, and G107 that would be much appreciated.

Thanks!

Thanks!