Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

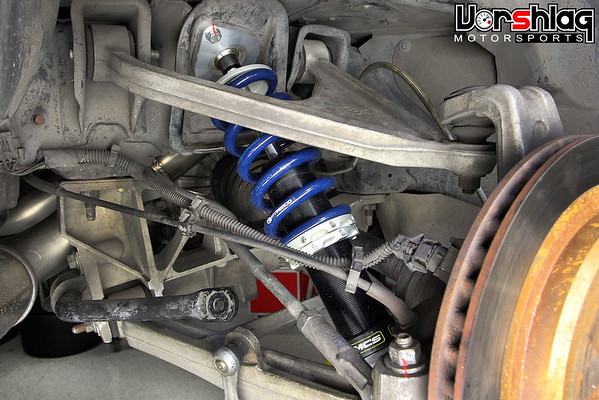

So I'm going through my 2007 front to back right now. It's pretty close to a chassis. I was looking at my shock mounts in the rear and they have two maybe urethane "bumpers" which sandwich the body/mount. They seem reasonably stout. But I just went full rod end on all the suspension stuff so it's a race car now. Fuck NVH, that is out the window.

I was thinking of making them out of delrin or something But then thought that they may need some articulation or I could run into side loading the shafts and wearing out the rods/bushings. Thoughts on that?

I guess I could use a couple of rose joints, make some receptacles, machine the shafts a bit and mount them "full race". But that is a lonng climb for a short slide. Anyone have thoughts on this.

Norm?

I was thinking of making them out of delrin or something But then thought that they may need some articulation or I could run into side loading the shafts and wearing out the rods/bushings. Thoughts on that?

I guess I could use a couple of rose joints, make some receptacles, machine the shafts a bit and mount them "full race". But that is a lonng climb for a short slide. Anyone have thoughts on this.

Norm?