UMI Performance HEAVY DUTY Lower Control Arm

Relocation Brackets PN 1060

Relocation Brackets PN 1060

UMI Performance proudly introduces the redesigned #1060 LCA Relocation Bracket!

http://umiperformance.com/catalog/index.php?main_page=product_info&cPath=12_184&products_id=319

Since 2009, we have been manufacturing relocation brackets for the S197 Mustangs. We used our in-house 2010 to prototype all of our S197 components, as well as track test our parts. Our Mustang has seen some abuse, with no failure.

We designed our LCA brackets PN 1060, to alleviate wheel-hop for the everyday driver who wants to roast some tire, as well as for drag racers who desire a firm and consistent launch. Our design has worked very well since 2009, with minimal failures. It took some quick slick-single-digit Mustangs to make the bolt-on bracket fail. Like anything as time passes, redesigns will occur.

We had some concern of the integrity of our parts triggered by the S197 Shelby owners. They were worried that a Mustang pushing 650+ HP with traction would cause failure. Though many of our Mustang customers consistently push 700HP with no issue, it’s never good to have any worries about failure in such a critical connection point.

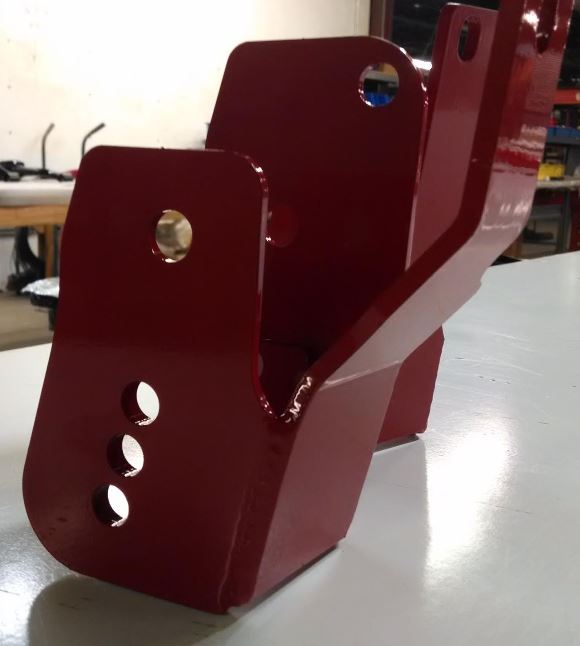

Many were concerned with the “twisted” appearance of the part. But, as you will see in the photo below, the LCA pocket has many compounding angles, none of which are perfectly parallel. So, we kept the “twist” and ran with it… Why not; it still fits and has provided us with great results for 5 years! There’s many ways to accomplish the same goal with different manufacturing methods… We felt making a bent piece would be imitating competitors. We also have faith in our welders providing plenty of penetration to the piece, actually causing this design to theoretically be stronger than a bent piece (work hardening occurs in bent metal, weakening that area unless heat treated).

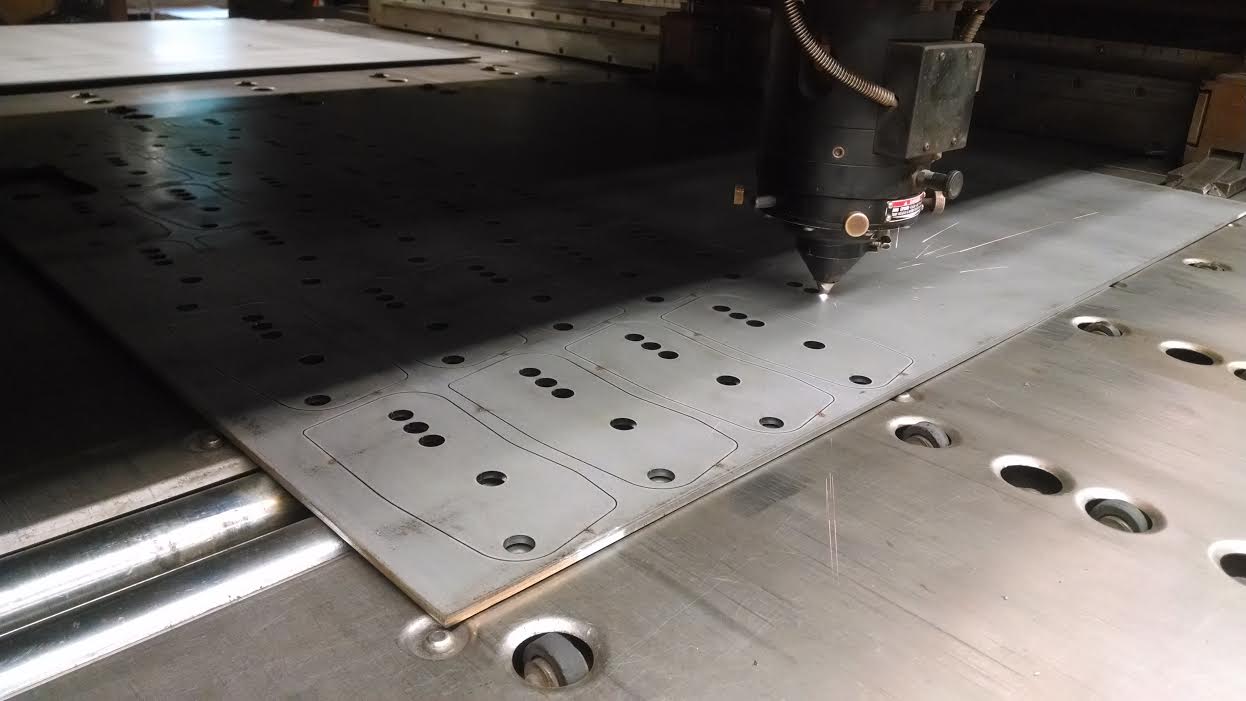

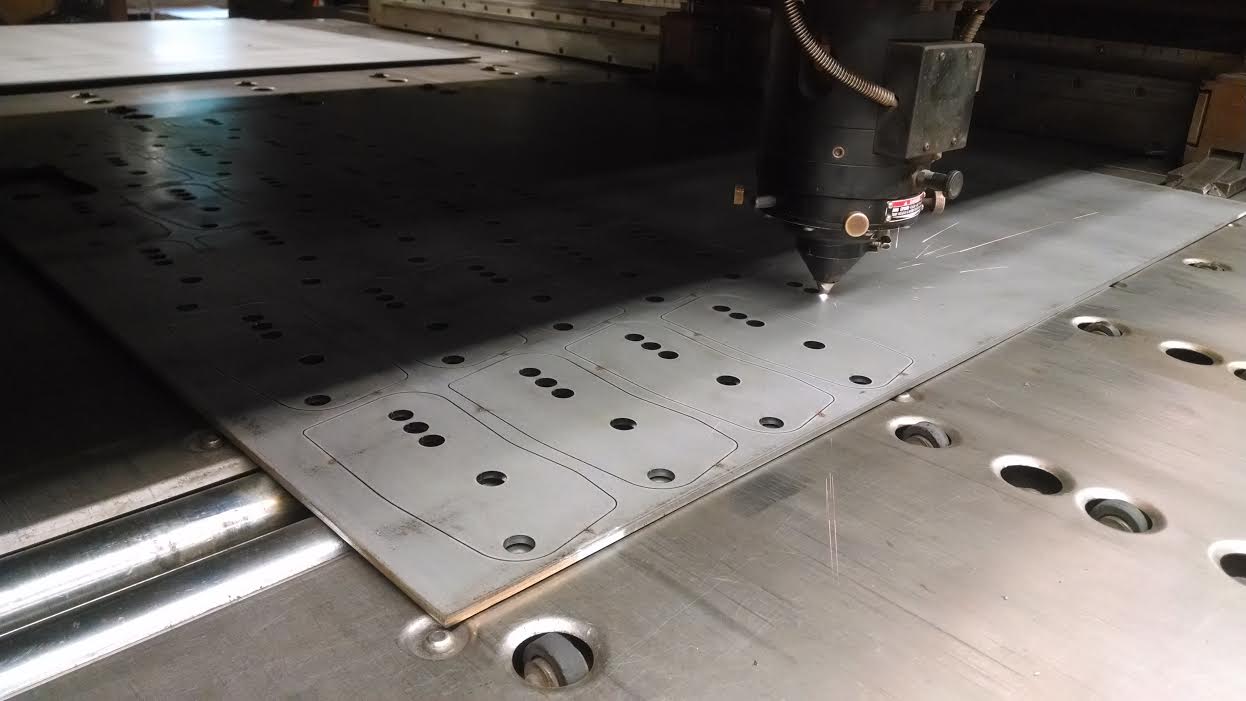

We decided to go to ¼” laser cut material for the bolt-on strapping. While thickening that, we extended the piece to allow a larger weld seat, which also left enough room to add a third hole for finer adjustability. Just for aesthetics we also added material around all the holes for a beefy appearance and for more weld seat for the reinforcement plate.

Once we tuned up our welding fixture, we made our first prototype and installed it. Took measurements in each hole to ensure the axle housing isn’t being offset in adjustments. We found it to fit just as the previous style did, with easy installation and consistent performance. Welded up a few sets and we’re ready for production!

We are very confident in this piece, just as we were with the previous design. The ¼” strapping will be ideal for any Mustang enthusiast who doesn’t want a bracket welded to their car. Let us know what you think about the revamped LCA relocation brackets! Might even be able to get a good deal to the first few customers

http://umiperformance.com/catalog/index.php?main_page=product_info&cPath=12_184&products_id=319

Since 2009, we have been manufacturing relocation brackets for the S197 Mustangs. We used our in-house 2010 to prototype all of our S197 components, as well as track test our parts. Our Mustang has seen some abuse, with no failure.

We designed our LCA brackets PN 1060, to alleviate wheel-hop for the everyday driver who wants to roast some tire, as well as for drag racers who desire a firm and consistent launch. Our design has worked very well since 2009, with minimal failures. It took some quick slick-single-digit Mustangs to make the bolt-on bracket fail. Like anything as time passes, redesigns will occur.

We had some concern of the integrity of our parts triggered by the S197 Shelby owners. They were worried that a Mustang pushing 650+ HP with traction would cause failure. Though many of our Mustang customers consistently push 700HP with no issue, it’s never good to have any worries about failure in such a critical connection point.

Many were concerned with the “twisted” appearance of the part. But, as you will see in the photo below, the LCA pocket has many compounding angles, none of which are perfectly parallel. So, we kept the “twist” and ran with it… Why not; it still fits and has provided us with great results for 5 years! There’s many ways to accomplish the same goal with different manufacturing methods… We felt making a bent piece would be imitating competitors. We also have faith in our welders providing plenty of penetration to the piece, actually causing this design to theoretically be stronger than a bent piece (work hardening occurs in bent metal, weakening that area unless heat treated).

We decided to go to ¼” laser cut material for the bolt-on strapping. While thickening that, we extended the piece to allow a larger weld seat, which also left enough room to add a third hole for finer adjustability. Just for aesthetics we also added material around all the holes for a beefy appearance and for more weld seat for the reinforcement plate.

Once we tuned up our welding fixture, we made our first prototype and installed it. Took measurements in each hole to ensure the axle housing isn’t being offset in adjustments. We found it to fit just as the previous style did, with easy installation and consistent performance. Welded up a few sets and we’re ready for production!

We are very confident in this piece, just as we were with the previous design. The ¼” strapping will be ideal for any Mustang enthusiast who doesn’t want a bracket welded to their car. Let us know what you think about the revamped LCA relocation brackets! Might even be able to get a good deal to the first few customers

Last edited: