GlassTop09

Senior Member

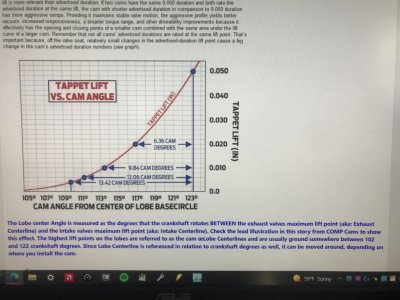

Ford provided cam data that I have of the OEM 4.6L Mustang production cams was given in advertised duration numbers, so I used my Lunati's cam card data converted to advertised duration numbers to get apples to apples numbers. Since VCT uses camshaft 0* as a reference is my hunch that Ford used advertised (.006" lift std) numbers. The actual valve lift lengths between .006" to .050" isn't very much at all (essentially takes the cam lobe initial ramp rate design out of the equation for comparison purposes between different manuf's cams) so I personally don't put too much weight in .050" lift making a big difference concerning injector EOIT to IVO timing vs .006" lift, but that's just me. This I do know, the advertised numbers match up exactly w\ the given stock injector reference IVO crank angle setting so that's all I can say.What is the actual lift at the valves when the injectors fire? Cam durations are referenced at 0.050 lift, thats why I asked that.

I played around with injector timing on my fox, ended up putting it back to stock. Ecam, blower 302, X303.

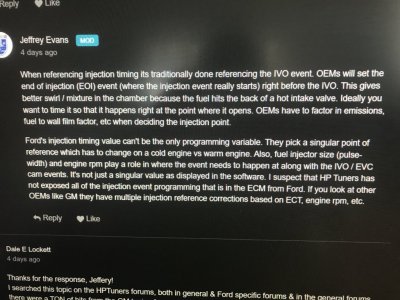

The big question I have is why so many aftermarket cams IVO's aren't referenced to match up w\ the Ford modeling for the stock cams so the injector EOIT lines up w\ the closed intake valves at point of opening to maintain the reasoning why Ford (and other manuf's) do this......you'd think fuel atomization off hot intake valves\mixing from swirl created by the initial rush of air entry from valve lift off the seat is a good enough reason to do the realignment, but from my research so far it appears that very few folks who tune Fords may actually do this w\ aftermarket camshafts. I'd like to know the reasoning as to why not.........does it have to do w\ most removing CMCV's (so swirl isn't that important anymore)? Is it due to FI usage so most just leave this setting stock out of habit? Is it due to the myth of intake air under vacuum being drawn out thru exhaust scavenging at low RPM's when exhaust is essentially at\slightly above atmospheric pressure (where EGR is usually applied w\ VCT)? Or is this just something that is done out of expediency? I don't know & it seems that a lot of Ford tuners either don't or won't have\provide any concrete data\reasoning as to why not to realign the injector reference IVO crank angle of an aftermarket cam to the injector EOIT point to match the Ford modeling intention......even Jeffery Evans didn't give any insight in my thread as to why not either, just explained what the OEM's traditional reasoning for setting this up in this way (which includes Ford as well).

By this reasoning it also raises another question as to why this setting was readjusted 4.5* later than stock in my tune file (makes some sense IMHO if the stock cams were still installed as being a fine adjustment. Hell, I don't even know if my prior tuner did this as I had a BAMA "race 91 oct" tune file in the PCM when I initially took it to him, but I DID have the stock cams in the engine at that time so there's that) but there's a good enough reasoning for that until the Lunati's went in.

I'll keep looking for an answer as I know this has to have been addressed by somebody at some point in time.