You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

05 to 09 coyote generation 2 swap! Guide and help tips

- Thread starter Jamie A

- Start date

-

- Tags

- coyote swap

Jamie A

Junior Member

Gen 1

Ok im doing gen 2 and ford control pack dosnt include the oss wire lead

Jamie A

Junior Member

Well the swap is already done and complete

Fabman

Children Of The Corn

Three questions:

1) I am swapping a gen2 into my 06 road race car using the Ford racing control pack.

The car has aftermarket dash/gauges, stand alone fuel pump and pretty much everything else is gone or stand alone so this is a simpler setup than most.

My question is how do I deal with the ABS?

If I remove the remainder of the stock wiring (which has been pared down to almost nothing already) what will talk to the ABS?

Do I need to run some or all of the old canbus/pcm etc. or can I pare that down further? Less is better, but I can't eliminate the ABS.

2) I see mentioned in various posts people changing the pilot bearing.

It that just a preventative maint. thing or is it different than the 05/09 bearing?

I'll be using the same Tremec magnum XL that I ran with the 3 valve.

3) How about my clutch, 8 Bolt alum flywheel and starter motor?

Is any of that retained or is the Coyote stuff different?

Thanks for any info.

1) I am swapping a gen2 into my 06 road race car using the Ford racing control pack.

The car has aftermarket dash/gauges, stand alone fuel pump and pretty much everything else is gone or stand alone so this is a simpler setup than most.

My question is how do I deal with the ABS?

If I remove the remainder of the stock wiring (which has been pared down to almost nothing already) what will talk to the ABS?

Do I need to run some or all of the old canbus/pcm etc. or can I pare that down further? Less is better, but I can't eliminate the ABS.

2) I see mentioned in various posts people changing the pilot bearing.

It that just a preventative maint. thing or is it different than the 05/09 bearing?

I'll be using the same Tremec magnum XL that I ran with the 3 valve.

3) How about my clutch, 8 Bolt alum flywheel and starter motor?

Is any of that retained or is the Coyote stuff different?

Thanks for any info.

Dino Dino Bambino

I have a red car

You can reuse the same tranny, clutch assembly, and flywheel, but you'd need the Coyote starter. The pilot bearing is cheap and easy to replace when the engine's out, so it would be a false economy not to.

Jamie A

Junior Member

Well i have solved the ac questioning and now is functional with the stock preassure switches!

Jamie A

Junior Member

Three questions:

1) I am swapping a gen2 into my 06 road race car using the Ford racing control pack.

The car has aftermarket dash/gauges, stand alone fuel pump and pretty much everything else is gone or stand alone so this is a simpler setup than most.

My question is how do I deal with the ABS?

If I remove the remainder of the stock wiring (which has been pared down to almost nothing already) what will talk to the ABS?

Do I need to run some or all of the old canbus/pcm etc. or can I pare that down further? Less is better, but I can't eliminate the ABS.

2) I see mentioned in various posts people changing the pilot bearing.

It that just a preventative maint. thing or is it different than the 05/09 bearing?

I'll be using the same Tremec magnum XL that I ran with the 3 valve.

3) How about my clutch, 8 Bolt alum flywheel and starter motor?

Is any of that retained or is the Coyote stuff different?

Thanks for any info.

Question 1

Abs is its own stand alone system that run off the smart junction box in the cab. And i think still pulls its tower from the electrical fuse box from the engine and does speak through to the cluster through the high speed can bus. The pcm only does traction control through the abs module for motor rpm drop to regain traction.

Question 2

They both use the same pilot bearing but in all regards when you do a clutch replacment or trans work always better to start fresh with a pilot bearing to know that wont fale on you.

Question 3

The clutch must be the 26 spline to mate to the tremec magnum xl. The 3650 trans is a 10 spline. A 8 bolt flywhell will be needed but a old 5.0 from fox body age will fit and only fit one exact bolt line up to the motor it can be stressful finding out one bolt wont line up then have to remove all bolts to spin the flywheel but it does fit.

Now your magnum xl you will need to use a orveride reverse lock out toggle switch or a after market converter box that splices to your oss output speed sensor to engage lock out over 5mph and disengage at 4mph or less to ise reverse

Your after market gauges might be a pain for rpm coolant and oil preassure since oil pressure isnt used on gen 2 motors and speedo and rpm are calibrated through the pcm and thrown over the high speed can bus (HS CAN). And coolant signal is sent can bus as well but stock 05 cluster recieves signal but can not read to display the language.

Great idea for a thread! I have some questions and maybe a few solutions we have run across I will share.

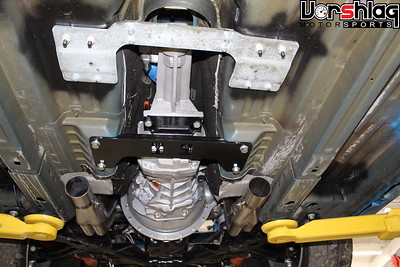

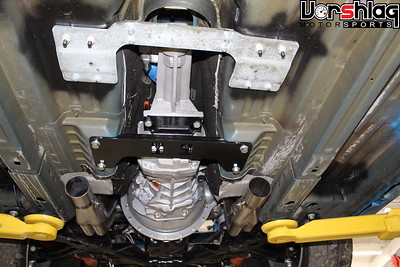

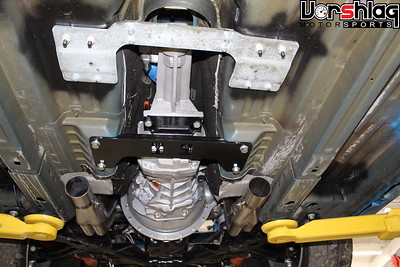

We have worked on a lot of Coyote powered cars, but only two Coyote swaps - and both were initially done by other shops. Both the E92 BMW (above) and Fox (below) swaps needed a LOT of clean up work and durability upgrades, which we tackled. The E92 became a proper track car after the work we did and the Fox became a much nicer, more functional street car.

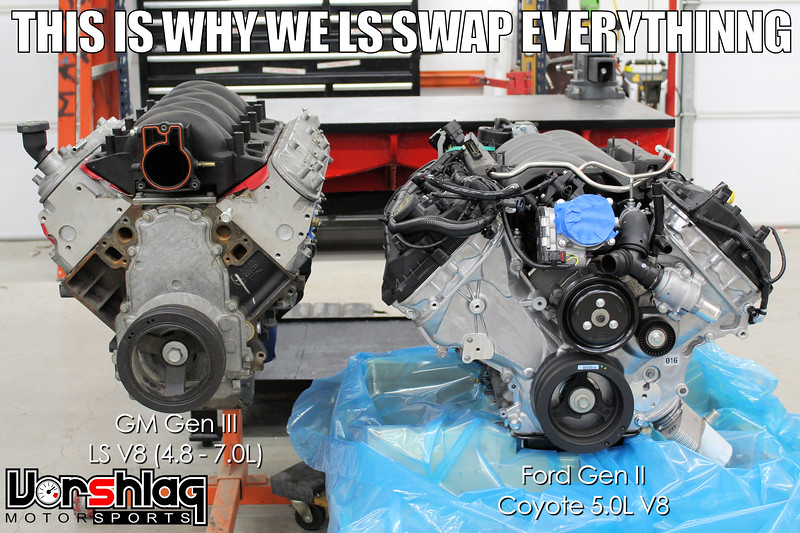

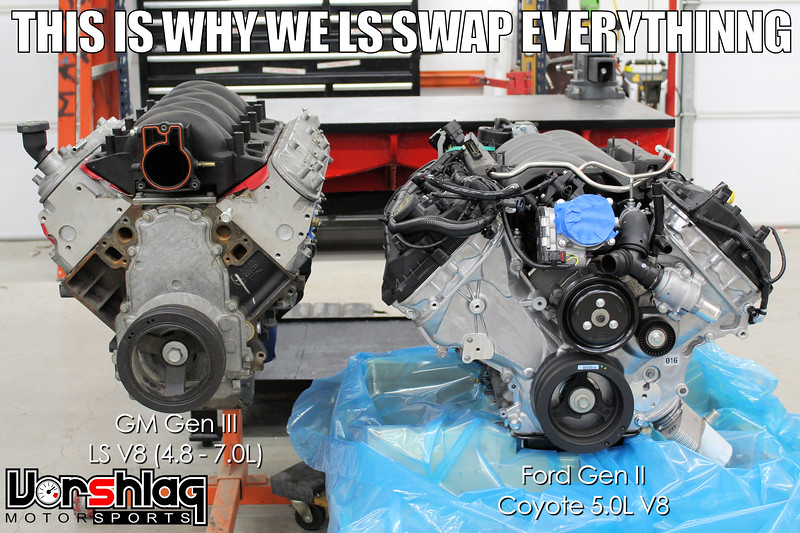

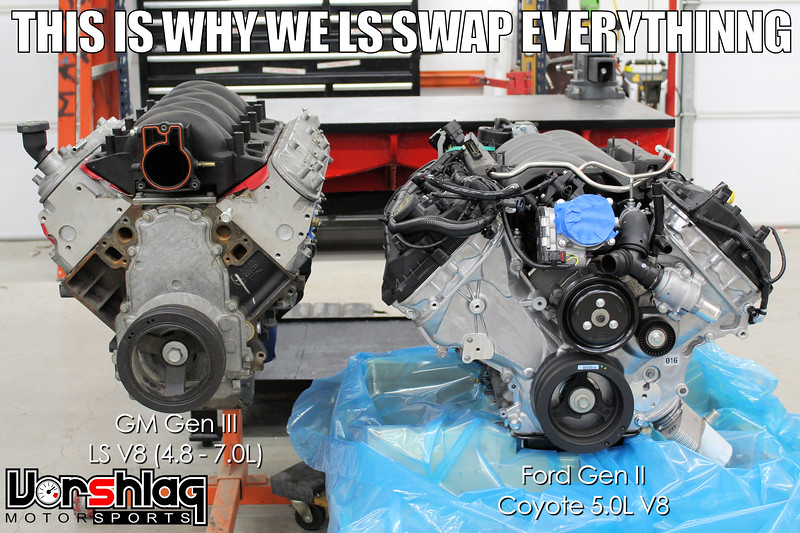

We have done dozens of LS swaps in-house and sold hundreds of LS swap kits. Why LS swap vs Coyote swap? Two reasons: COST and SIZE. A built Coyote is pretty damned expensive and for a road race car might make 500 whp, but they are usually short lived. You get it past 5.2L and you spent some SERIOUS money. A Built LS is common and can go to 8.0L inside an OEM block (and 8.7L in tall deck). I'm not guessing, we've done this, a lot, at my engine shop Horsepower Research. This image shows the size thing...

I'm not arguing for LS swaps, just have to always put that out there as a warning. Now we have a customer that asked us to upgrade his 2010 GT which had the lackluster 4.6L 3V engine. 300-315 hp, makes 260-280 whp in NA form with some headers, CAI and tune. Wee!

He wants to move out of the class he was in (NASA Spec Iron) to a class that allows +100 whp (American Iron). Our suggestion was to over shoot the ~370 whp the class allows and go for a Gen 2 Coyote swap, make 450 whp, then use the electronic throttle to restrict the tune to make a "flat power" 370 whp across the board. Old trick, really works. Uncork it for fun events and let it fly!

He went with a Tremec T56 Magnum XL, ARH long tubes, Gen 2 crate motor, and the Ford controls pack.

We have found a lot of part numbers for Gen2 specific parts we need, made a lot of little brackets and doo-dads to make the Controls Pack bits fit, and have the swap mostly done. I will post more here as work progresses. Now I'm gonna go back and read every post and see if we can get some help with:

1. Making the stock gauges work (doubtful - will likely use AiM digital dash)

2. Get some ideas on making a 2011-14 EPAS electric rack (Boss302R rack) working

The wiring and CAN comms are always the hardest part of any swap, and this looks no different. Except that there seems to be only ONE source for a wiring harness to work with the OEM computer (Ford). And there seems to be no way to make one street legal (which is what about half of our LS swaps end up doing).

More soon,

We have worked on a lot of Coyote powered cars, but only two Coyote swaps - and both were initially done by other shops. Both the E92 BMW (above) and Fox (below) swaps needed a LOT of clean up work and durability upgrades, which we tackled. The E92 became a proper track car after the work we did and the Fox became a much nicer, more functional street car.

We have done dozens of LS swaps in-house and sold hundreds of LS swap kits. Why LS swap vs Coyote swap? Two reasons: COST and SIZE. A built Coyote is pretty damned expensive and for a road race car might make 500 whp, but they are usually short lived. You get it past 5.2L and you spent some SERIOUS money. A Built LS is common and can go to 8.0L inside an OEM block (and 8.7L in tall deck). I'm not guessing, we've done this, a lot, at my engine shop Horsepower Research. This image shows the size thing...

I'm not arguing for LS swaps, just have to always put that out there as a warning. Now we have a customer that asked us to upgrade his 2010 GT which had the lackluster 4.6L 3V engine. 300-315 hp, makes 260-280 whp in NA form with some headers, CAI and tune. Wee!

He wants to move out of the class he was in (NASA Spec Iron) to a class that allows +100 whp (American Iron). Our suggestion was to over shoot the ~370 whp the class allows and go for a Gen 2 Coyote swap, make 450 whp, then use the electronic throttle to restrict the tune to make a "flat power" 370 whp across the board. Old trick, really works. Uncork it for fun events and let it fly!

He went with a Tremec T56 Magnum XL, ARH long tubes, Gen 2 crate motor, and the Ford controls pack.

We have found a lot of part numbers for Gen2 specific parts we need, made a lot of little brackets and doo-dads to make the Controls Pack bits fit, and have the swap mostly done. I will post more here as work progresses. Now I'm gonna go back and read every post and see if we can get some help with:

1. Making the stock gauges work (doubtful - will likely use AiM digital dash)

2. Get some ideas on making a 2011-14 EPAS electric rack (Boss302R rack) working

The wiring and CAN comms are always the hardest part of any swap, and this looks no different. Except that there seems to be only ONE source for a wiring harness to work with the OEM computer (Ford). And there seems to be no way to make one street legal (which is what about half of our LS swaps end up doing).

More soon,

Jamie A

Junior Member

Great idea for a thread! I have some questions and maybe a few solutions we have run across I will share.

We have worked on a lot of Coyote powered cars, but only two Coyote swaps - and both were initially done by other shops. Both the E92 BMW (above) and Fox (below) swaps needed a LOT of clean up work and durability upgrades, which we tackled. The E92 became a proper track car after the work we did and the Fox became a much nicer, more functional street car.

We have done dozens of LS swaps in-house and sold hundreds of LS swap kits. Why LS swap vs Coyote swap? Two reasons: COST and SIZE. A built Coyote is pretty damned expensive and for a road race car might make 500 whp, but they are usually short lived. You get it past 5.2L and you spent some SERIOUS money. A Built LS is common and can go to 8.0L inside an OEM block (and 8.7L in tall deck). I'm not guessing, we've done this, a lot, at my engine shop Horsepower Research. This image shows the size thing...

I'm not arguing for LS swaps, just have to always put that out there as a warning. Now we have a customer that asked us to upgrade his 2010 GT which had the lackluster 4.6L 3V engine. 300-315 hp, makes 260-280 whp in NA form with some headers, CAI and tune. Wee!

He wants to move out of the class he was in (NASA Spec Iron) to a class that allows +100 whp (American Iron). Our suggestion was to over shoot the ~370 whp the class allows and go for a Gen 2 Coyote swap, make 450 whp, then use the electronic throttle to restrict the tune to make a "flat power" 370 whp across the board. Old trick, really works. Uncork it for fun events and let it fly!

He went with a Tremec T56 Magnum XL, ARH long tubes, Gen 2 crate motor, and the Ford controls pack.

We have found a lot of part numbers for Gen2 specific parts we need, made a lot of little brackets and doo-dads to make the Controls Pack bits fit, and have the swap mostly done. I will post more here as work progresses. Now I'm gonna go back and read every post and see if we can get some help with:

1. Making the stock gauges work (doubtful - will likely use AiM digital dash)

2. Get some ideas on making a 2011-14 EPAS electric rack (Boss302R rack) working

The wiring and CAN comms are always the hardest part of any swap, and this looks no different. Except that there seems to be only ONE source for a wiring harness to work with the OEM computer (Ford). And there seems to be no way to make one street legal (which is what about half of our LS swaps end up doing).

#1 making the stock gauges work is only able to get half to work.

1. Oil preassyre is off a dummy switch that only petrays if there is ground created. its the gray wire where the engine harness and body harness connevt by a kind of chunky swuare connector.

2. The fuel still communicates as normal as long as you are still using the same float and connector ontop from stock pump. I used aeromotive a1000 fuel pump and they adapt the float to attach to it. Or power by the hour has a return style fuel hat that is about identical to stock style.

3. Collant gauge does not read from the coyote pcm to the cluster. The cluster does signify it is recieveing signal but is in a different PPM that the cluster is unable to display it. I routed to using the heater core hose and aftermarket gauge to pull temp.

4. Rpm works perfect just by connecting the original HS can bus wires to the coyote HS can bus wires.

5. battery will read from can bus but some have ran i to issue of battery light staying lit due to over charge beacause the altenators are 200 amp or they just dont register the altenatir operating but the battery gauge functions perfectly.

6. Now funny one is the speedometer. I jave tried every which way to get the 2 wire oss to convert to 3 wire communications to the pcm using a dakota sgi 5e, adding resistor, hooking staright to pcm ect. But nothing works. I know gen 1 they had issues of stalling at stops due to no oss signal and you had to pin the pcm connector for the oss to stop this issue. Now in gen 2 what i have noticed is if you tap the gas it dies to an 850 rpm idle for 8 seconds and then jumps up to 950 rpm and stays there until gas is pressed again even if you have drove for hours. I have hooked up a scanner and seen in the live data even sitting at still idle the vehicle speed in the active data reads 40kmh and never changes. So what i think is the deal is that ford performance reflashed the pcm to mimic that the car is always registering itself moving to stop, stoping and stalling issues likenthey had in gen 1 swaps. So i think to get that speedometer to work again is pcm reprograming.

2. The boss302 electronic rack. No question at all in the gen 2 ford wiring controls pack the already have a 12v accessory lead with the HS can + and HS can - that are ment for the EPAS (302 rack) just have to wire them up to it and it shall we ready to rock.

More soon,

Fabman

Children Of The Corn

You can reuse the same tranny, clutch assembly, and flywheel, but you'd need the Coyote starter. The pilot bearing is cheap and easy to replace when the engine's out, so it would be a false economy not to.

Question 1

Abs is its own stand alone system that run off the smart junction box in the cab. And i think still pulls its tower from the electrical fuse box from the engine and does speak through to the cluster through the high speed can bus. The pcm only does traction control through the abs module for motor rpm drop to regain traction.

Question 2

They both use the same pilot bearing but in all regards when you do a clutch replacment or trans work always better to start fresh with a pilot bearing to know that wont fale on you.

Question 3

The clutch must be the 26 spline to mate to the tremec magnum xl. The 3650 trans is a 10 spline. A 8 bolt flywhell will be needed but a old 5.0 from fox body age will fit and only fit one exact bolt line up to the motor it can be stressful finding out one bolt wont line up then have to remove all bolts to spin the flywheel but it does fit.

Now your magnum xl you will need to use a orveride reverse lock out toggle switch or a after market converter box that splices to your oss output speed sensor to engage lock out over 5mph and disengage at 4mph or less to ise reverse

Your after market gauges might be a pain for rpm coolant and oil preassure since oil pressure isnt used on gen 2 motors and speedo and rpm are calibrated through the pcm and thrown over the high speed can bus (HS CAN). And coolant signal is sent can bus as well but stock 05 cluster recieves signal but can not read to display the language.

Good information, thank you.

This is the dash, so I don't have to deal with the cluster at all.

I just have to run the motor, the ABS, light up the tail lights and run the Fuel pump which is a stand alone unit already. If I could dump the rest of the existing wire harness and fuse box for a simpler set up I'd love to....but I don't want to open a pandora's box if I can help it.

Last edited:

Jamie A

Junior Member

Good information, thank you.

This is the dash, so I don't have to deal with the cluster at all.

I just have to run the motor, the ABS, light up the tail lights and run the Fuel pump which is a stand alone unit already. If I could dump the rest of the existing wire harness and fuse box for a simpler set up I'd love to....but I don't want to open a pandora's box if I can help it.

View attachment 70315

Tgen you should be all fine. The abs runs off of the sbj (smart junsction box) as well the brake lights go through the stock body harness. The only tricky part is if you need to have reverse lights fucntioning again which was activated by the pcm and just have to wire up through a secondary relay style to activate

Fabman

Children Of The Corn

No reverse lights needed. I'd sure like to have the reverse lockout work, with it non operational its easy to miss the 5th gear gate and slide into the reverse gate in the heat of battle.Tgen you should be all fine. The abs runs off of the sbj (smart junsction box) as well the brake lights go through the stock body harness. The only tricky part is if you need to have reverse lights fucntioning again which was activated by the pcm and just have to wire up through a secondary relay style to activate

A toggle sounds easy enough but might be a pain in an emergency situation....you mentioned a converter box but I'm not sure if something like that would work with most of the stock wiring harness removed...there's no speedo or anything.....

Jamie A

Junior Member

No reverse lights needed. I'd sure like to have the reverse lockout work, with it non operational its easy to miss the 5th gear gate and slide into the reverse gate in the heat of battle.

A toggle sounds easy enough but might be a pain in an emergency situation....you mentioned a converter box but I'm not sure if something like that would work with most of the stock wiring harness removed...there's no speedo or anything.....

Well as long as you have a speed sensor if im not mistaken you can just wire the lock out box they make to the speed sensor and it activates reverse lock out at 5mhp and up

race4food

forum member

Some one please kick him in the balls...if you are gonna do and engine swap put a 7 liter GM LT1, all aluminum and plenty of cubes...kev

Big update to our Gen II Coyote swap 2010 Mustang GT / Spec Iron to American Iron thread: https://www.s197forum.com/threads/vorshlag-gen2-coyote-swap-in-2010-mustang.136536/

jolambright

forum member

Why not just buy a rear ended 11-14 gt for 8-12k and swap everything, and maybe just have to buy a mt82/T56 magnum/6r80 extra if the tranny is unusable from the 11-14?

That way you have the dash and everything working in the car like oem with only some minor things need adjusted.

That way you have the dash and everything working in the car like oem with only some minor things need adjusted.

Greg D

Junior Member

I have compiled a S197 RACE ONLY Gen 2 detailed swap list with prices on an Exel spreadsheet. This means no A/C, no smog controls, catalytics, etc. etc. If anyone is interested, I'll be happy to share it. It does use a lot of the Power By The Hour swap parts.

Philip Sohn

Junior Member

- Joined

- Sep 20, 2020

- Posts

- 2

- Reaction score

- 0

I want to swap my 06 v6 what do I need?

Dino Dino Bambino

I have a red car

I want to swap my 06 v6 what do I need?

You really need a totaled but complete '11-'14 GT to use as a parts donor, lots of time on your hands, a buddy to help you with some tasks, tools/equipment, several jack stands or a two-post lift, and a pocketful of cash to buy some of those "gotcha" replacement parts you'll inevitably need, plus all the required fluids.

Similar threads

- Replies

- 30

- Views

- 8K

- Replies

- 0

- Views

- 931

- Replies

- 0

- Views

- 1K

- Replies

- 12

- Views

- 6K

- Replies

- 25

- Views

- 6K

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details