GlassTop09

Senior Member

Update:

We put her on the dyno today & got her all tuned up w\ these Lunati VooDoo #21270700 cams installed (only item that was changed on the engine that will matter....replaced OEM Ford production cams & also replaced OEM valve covers w\ FR Black Wrinkle Etched valve covers--bling).

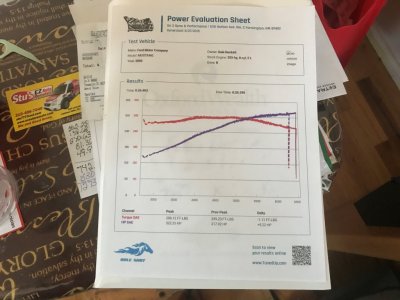

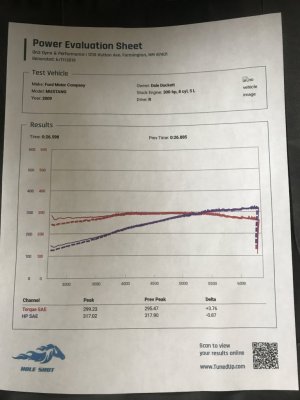

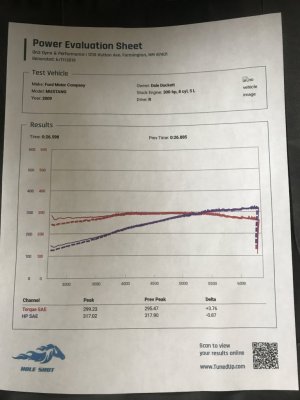

1st thing to put into context, the new On3 Performance speed shop uses a Mustang dyno instead of a DynoJet dyno that Optimum Force (the shop where my tuner was contracted thru during the initial tuning work) uses so we aren't gonna be looking at apples to apples comparison w\ the prior dyno sheet I posted earlier. Both dyno sheet's results were corrected @ SAE. The best we're gonna do here is use some math to get a better comparison as my tuner said that the difference between the 2 dyno types typically falls between 8%-10% depending upon equipment condition\setup\calibration being relatively on par as long as the correct weight of the vehicle is loaded properly w\ them. Was told that a Mustang dyno will usually induce a heavier load on the drive wheels vs a DynoJet w\ all else being equal thus why they usually show lower numbers. The main thing thru all of this is how does the car drive\feel\perform after tuning vs before.....the drag strip\road course is usually the better place to determine this as they are timed events that can reveal the general total improvement\regression of the parts installed/work done.

But there is data to be gained from looking at the dyno sheet showing "area under the curve" performance.....

Now that that's out of the way, here she is...……………………….

At peak final numbers were 317.02 HP/299.23 TQ (vs 317.90 HP/295.47 TQ baseline) w\ the Lunati VooDoo #21270700 cams on On3's Mustang dyno. This correlates to DynoJet correction of final On3 Mustang dyno peak numbers of same FBO's running Lunati VooDoo #21270700 cams to compare to OF DynoJet peak numbers using math of same FBO's running OEM cams at 8% @ 342.38 HP/ 323.17 TQ or at 10% @ 348.72 HP/ 329.15 TQ so the net final peak comparison at 8% @ +11.78 HP/-2.73 TQ, at 10% @ +18.12 HP/+3.25 TQ vs the OF dyno sheet results. As you can see, the On3 dyno sheet doesn't show the final peak HP/TQ RPM markers to compare to the OF dyno sheet's peak HP/TQ RPM markers where peak numbers were reached (forgot to ask my tuner for this info at the time but can get it later) to determine the shift in the curve higher or lower. Now looking at the On3 sheet at 2500 RPM (low end of graph) we have final peak numbers of 139 HP/285 TQ (vs 125 HP/245 TQ baseline....measured 5/8" between HP/TQ markers which gives 9-1/16" "scaling marks" so matched up w\ graph) w\ Lunati VooDoo's. Using the same math to correlate to the OF DynoJet sheet at the same 2500 RPM mark w\ OEM cams (final @ 130 HP/270 TQ) the On3 Mustang sheet to DynoJet correction finals at 8% @ 150.12 HP/307.8 TQ, at 10% @ 152.9 HP/313.5 TQ so the net final comparison at 8% @ +20.12 HP/+37.8 TQ, at 10% @ +22.9 HP/+43.5 TQ @ same 2500 RPM. So assuming all is theretically apples to apples, the Lunati VooDoo's are giving a larger performance gain at lower RPM's than at upper RPM's vs OEM's.....for HP the gains are across the entire curve at both 8% & 10% corrections but for TQ the gains are larger at lower RPM's for both 8% & 10% corrections but at 8% peak TQ correction we lose 2.73 lb\ft vs 10% peak TQ correction we gain 3.25 lb/ft.

Now notice the dip in HP & TQ right off the 2500 RPM mark on the On3 dyno sheet then it levels into the steady rise from there. This happened from the ECU doing what I posted about in post #19 as I am still running cats so the ECU is still using the 2 post cat O2 sensors....my tuner has this recorded as well (I'll see if I can get a copy of the data logging that shows it). He had fixed this as best he could under the circumstances by resetting the VCT cam retard setting limits to get the most HP/TQ down low but still not screw up the cats so I'll have to live w\ that unless I remove the cats & turn off the rear O2 sensors. Good thing is when driving the car I never really noticed it thru these 3.73 gears/26" tires so a moot point.

The other things we noted is that around 3500-3800 RPM there is some outside harmonics going on that is causing some false knock so ECU pulls some spark timing momentarily then it goes away after that. I think I know what's going on (got exhaust piping\clamp most likely hitting unibody due to vibrations from exhaust frequency within this RPM range....I noticed 1 clamp is actually touching gas tank guard but may also be 1 of the cats hitting underside from me having exhaust supports installed on mid pipe at trans crossmember....all is very close to unibody, may be hitting due to exhaust piping moving from expansion) so I'm gonna pick up some 5/8" flat washers to use as spacers to gain some more clearance & rotate the 1 clamp to clear the gas tank guard...should fix this. Also around 5700 RPM the engine starts to run out of air (injectors DC around 78%-80% so FP is keeping up so fuel delivery isn't the issue) but not enough to cause the HP/TQ to nose dive so HP is still slowly gaining but at a slower rate. My tuner thinks that this is due to the limits of my FR Bullit 85mm CAI, not due to the Lunati VooDoo #21270700 cams. He says from what he's seeing these Lunati VooDoo cams (thus my engine) got more gains to give up on top, but since these are a mild cam grind to begin with & this would only be important to go after if racing was the goal (which would be better served here w\ a more aggressive cam profile along w\ a SC install anyway & racing is FAR down on my list of priorities w\ this Glass Top Stang due to it's rarity) I'm gonna call her good at this point.

Had the hot idle set RPM lowered from 790 to 750 (I had raised idle RPM back when engine was all stock on OEM 87oct Ford tune w\ 3.55 gears due to struggles on TO w\ A/C on & just left it as set until now). This brought out the exhaust cadence more (not a chopping lope but a rolling rumble) that I was hearing after I installed these Lunati's along w\ an even deeper exhaust note thru my Pypes Super Bomb Mid-Muffler catback system w\ them 14" x 4" resonators....sounding sooo good to me now (wife told me that she heard me backing into driveway from the back bedroom of our house thru closed door......neighbors ain't gonna like me driving in\out at night). The rumble is fairly smooth but no resemblance to the sound from the OEM cams, probably due to the slightly larger valve overlap in the Lunati's. With the increased low end torque gains from the Lunati's vs the OEM's the car drives even better than before even at the lower 750 RPM idle w\ the A/C on to boot....just walks off in 1st w\o any throttle input & the power comes on very smooth but QUICK once throttle input is applied so she is a little more touchy than prior on throttle management at low RPM but this I LIKE.

Was starting to rain so I parked the car for the rest of the day. Plan to take her on a ECU relearn drive in the AM if weather permits.

So all in all I'm happy w\ these Lunati VooDoo #21270700 cam's performance vs the stock OEM cams....should make cruising a very pleasant & fun experience!

We put her on the dyno today & got her all tuned up w\ these Lunati VooDoo #21270700 cams installed (only item that was changed on the engine that will matter....replaced OEM Ford production cams & also replaced OEM valve covers w\ FR Black Wrinkle Etched valve covers--bling).

1st thing to put into context, the new On3 Performance speed shop uses a Mustang dyno instead of a DynoJet dyno that Optimum Force (the shop where my tuner was contracted thru during the initial tuning work) uses so we aren't gonna be looking at apples to apples comparison w\ the prior dyno sheet I posted earlier. Both dyno sheet's results were corrected @ SAE. The best we're gonna do here is use some math to get a better comparison as my tuner said that the difference between the 2 dyno types typically falls between 8%-10% depending upon equipment condition\setup\calibration being relatively on par as long as the correct weight of the vehicle is loaded properly w\ them. Was told that a Mustang dyno will usually induce a heavier load on the drive wheels vs a DynoJet w\ all else being equal thus why they usually show lower numbers. The main thing thru all of this is how does the car drive\feel\perform after tuning vs before.....the drag strip\road course is usually the better place to determine this as they are timed events that can reveal the general total improvement\regression of the parts installed/work done.

But there is data to be gained from looking at the dyno sheet showing "area under the curve" performance.....

Now that that's out of the way, here she is...……………………….

At peak final numbers were 317.02 HP/299.23 TQ (vs 317.90 HP/295.47 TQ baseline) w\ the Lunati VooDoo #21270700 cams on On3's Mustang dyno. This correlates to DynoJet correction of final On3 Mustang dyno peak numbers of same FBO's running Lunati VooDoo #21270700 cams to compare to OF DynoJet peak numbers using math of same FBO's running OEM cams at 8% @ 342.38 HP/ 323.17 TQ or at 10% @ 348.72 HP/ 329.15 TQ so the net final peak comparison at 8% @ +11.78 HP/-2.73 TQ, at 10% @ +18.12 HP/+3.25 TQ vs the OF dyno sheet results. As you can see, the On3 dyno sheet doesn't show the final peak HP/TQ RPM markers to compare to the OF dyno sheet's peak HP/TQ RPM markers where peak numbers were reached (forgot to ask my tuner for this info at the time but can get it later) to determine the shift in the curve higher or lower. Now looking at the On3 sheet at 2500 RPM (low end of graph) we have final peak numbers of 139 HP/285 TQ (vs 125 HP/245 TQ baseline....measured 5/8" between HP/TQ markers which gives 9-1/16" "scaling marks" so matched up w\ graph) w\ Lunati VooDoo's. Using the same math to correlate to the OF DynoJet sheet at the same 2500 RPM mark w\ OEM cams (final @ 130 HP/270 TQ) the On3 Mustang sheet to DynoJet correction finals at 8% @ 150.12 HP/307.8 TQ, at 10% @ 152.9 HP/313.5 TQ so the net final comparison at 8% @ +20.12 HP/+37.8 TQ, at 10% @ +22.9 HP/+43.5 TQ @ same 2500 RPM. So assuming all is theretically apples to apples, the Lunati VooDoo's are giving a larger performance gain at lower RPM's than at upper RPM's vs OEM's.....for HP the gains are across the entire curve at both 8% & 10% corrections but for TQ the gains are larger at lower RPM's for both 8% & 10% corrections but at 8% peak TQ correction we lose 2.73 lb\ft vs 10% peak TQ correction we gain 3.25 lb/ft.

Now notice the dip in HP & TQ right off the 2500 RPM mark on the On3 dyno sheet then it levels into the steady rise from there. This happened from the ECU doing what I posted about in post #19 as I am still running cats so the ECU is still using the 2 post cat O2 sensors....my tuner has this recorded as well (I'll see if I can get a copy of the data logging that shows it). He had fixed this as best he could under the circumstances by resetting the VCT cam retard setting limits to get the most HP/TQ down low but still not screw up the cats so I'll have to live w\ that unless I remove the cats & turn off the rear O2 sensors. Good thing is when driving the car I never really noticed it thru these 3.73 gears/26" tires so a moot point.

The other things we noted is that around 3500-3800 RPM there is some outside harmonics going on that is causing some false knock so ECU pulls some spark timing momentarily then it goes away after that. I think I know what's going on (got exhaust piping\clamp most likely hitting unibody due to vibrations from exhaust frequency within this RPM range....I noticed 1 clamp is actually touching gas tank guard but may also be 1 of the cats hitting underside from me having exhaust supports installed on mid pipe at trans crossmember....all is very close to unibody, may be hitting due to exhaust piping moving from expansion) so I'm gonna pick up some 5/8" flat washers to use as spacers to gain some more clearance & rotate the 1 clamp to clear the gas tank guard...should fix this. Also around 5700 RPM the engine starts to run out of air (injectors DC around 78%-80% so FP is keeping up so fuel delivery isn't the issue) but not enough to cause the HP/TQ to nose dive so HP is still slowly gaining but at a slower rate. My tuner thinks that this is due to the limits of my FR Bullit 85mm CAI, not due to the Lunati VooDoo #21270700 cams. He says from what he's seeing these Lunati VooDoo cams (thus my engine) got more gains to give up on top, but since these are a mild cam grind to begin with & this would only be important to go after if racing was the goal (which would be better served here w\ a more aggressive cam profile along w\ a SC install anyway & racing is FAR down on my list of priorities w\ this Glass Top Stang due to it's rarity) I'm gonna call her good at this point.

Had the hot idle set RPM lowered from 790 to 750 (I had raised idle RPM back when engine was all stock on OEM 87oct Ford tune w\ 3.55 gears due to struggles on TO w\ A/C on & just left it as set until now). This brought out the exhaust cadence more (not a chopping lope but a rolling rumble) that I was hearing after I installed these Lunati's along w\ an even deeper exhaust note thru my Pypes Super Bomb Mid-Muffler catback system w\ them 14" x 4" resonators....sounding sooo good to me now (wife told me that she heard me backing into driveway from the back bedroom of our house thru closed door......neighbors ain't gonna like me driving in\out at night). The rumble is fairly smooth but no resemblance to the sound from the OEM cams, probably due to the slightly larger valve overlap in the Lunati's. With the increased low end torque gains from the Lunati's vs the OEM's the car drives even better than before even at the lower 750 RPM idle w\ the A/C on to boot....just walks off in 1st w\o any throttle input & the power comes on very smooth but QUICK once throttle input is applied so she is a little more touchy than prior on throttle management at low RPM but this I LIKE.

Was starting to rain so I parked the car for the rest of the day. Plan to take her on a ECU relearn drive in the AM if weather permits.

So all in all I'm happy w\ these Lunati VooDoo #21270700 cam's performance vs the stock OEM cams....should make cruising a very pleasant & fun experience!