Aussie-Parnelli

Junior Member

Hi

I have a heavily modified Saleen S197 which I took to the dyno several weeks ago. The car was running fine when I dropped it off.

Got a call to say there was an issue and was in limp mode

Unfortunately here in Australia there are not many S197's

Took the car home and it will only start with the throttle body disconnected and run in the limp mode

Tried reinstalling previous tune but to no avail.

With the throttle body connected it is making a chattering sound and won't turn over

It is showing these codes P2107 and P2110

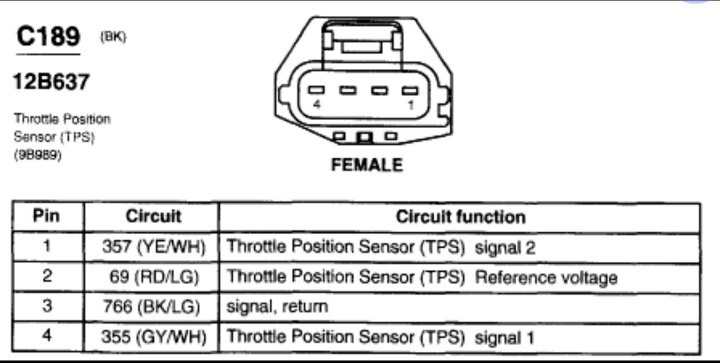

Cannot clear these codes with my SCT tuner. Have 3.87 volts at each pin

Have put a new throttle body on.....same issue

Have changed numerous parts off one of my other S197's still same problem

Checked all fuses and relays plus earths....still nothing

The dash is showing "check charging system" and "DTE Data Error"

Running out of options any ideas or help would be appreciated

I have a heavily modified Saleen S197 which I took to the dyno several weeks ago. The car was running fine when I dropped it off.

Got a call to say there was an issue and was in limp mode

Unfortunately here in Australia there are not many S197's

Took the car home and it will only start with the throttle body disconnected and run in the limp mode

Tried reinstalling previous tune but to no avail.

With the throttle body connected it is making a chattering sound and won't turn over

It is showing these codes P2107 and P2110

Cannot clear these codes with my SCT tuner. Have 3.87 volts at each pin

Have put a new throttle body on.....same issue

Have changed numerous parts off one of my other S197's still same problem

Checked all fuses and relays plus earths....still nothing

The dash is showing "check charging system" and "DTE Data Error"

Running out of options any ideas or help would be appreciated

Last edited: