Mustangk

Junior Member

- Joined

- Jan 3, 2020

- Posts

- 43

- Reaction score

- 2

so there i am waiting for the red left light to turn green and i rev the rpms up and let go of clutch as the turn light turns green and all i hear is tink tink tink as apparently my ?idler pulley?{i think thats what its called} falls to the ground and bounces into the curb, KEY NOTE HERE: the engine still is running fine and i begin to question if i ran something over or if something fell off my engine, as i had recently done work to the motor mounts and a blowfish bracket, i pull over and get out of my car to check if something fell off the engine.,

Sure enough my idler pulley the one that is right above the tensioner and to the right and just SEEMS TO JUST SLIGHTLY PUSH ON THE BELT A BIT TO INCREASE THE TENSION ON IT is on the ground, i couldnt find the bolt.

CARS STILL SEEMS TO RUN FINE ALTHO THE BELT SEEMS TO BE A BIT LOOSE.

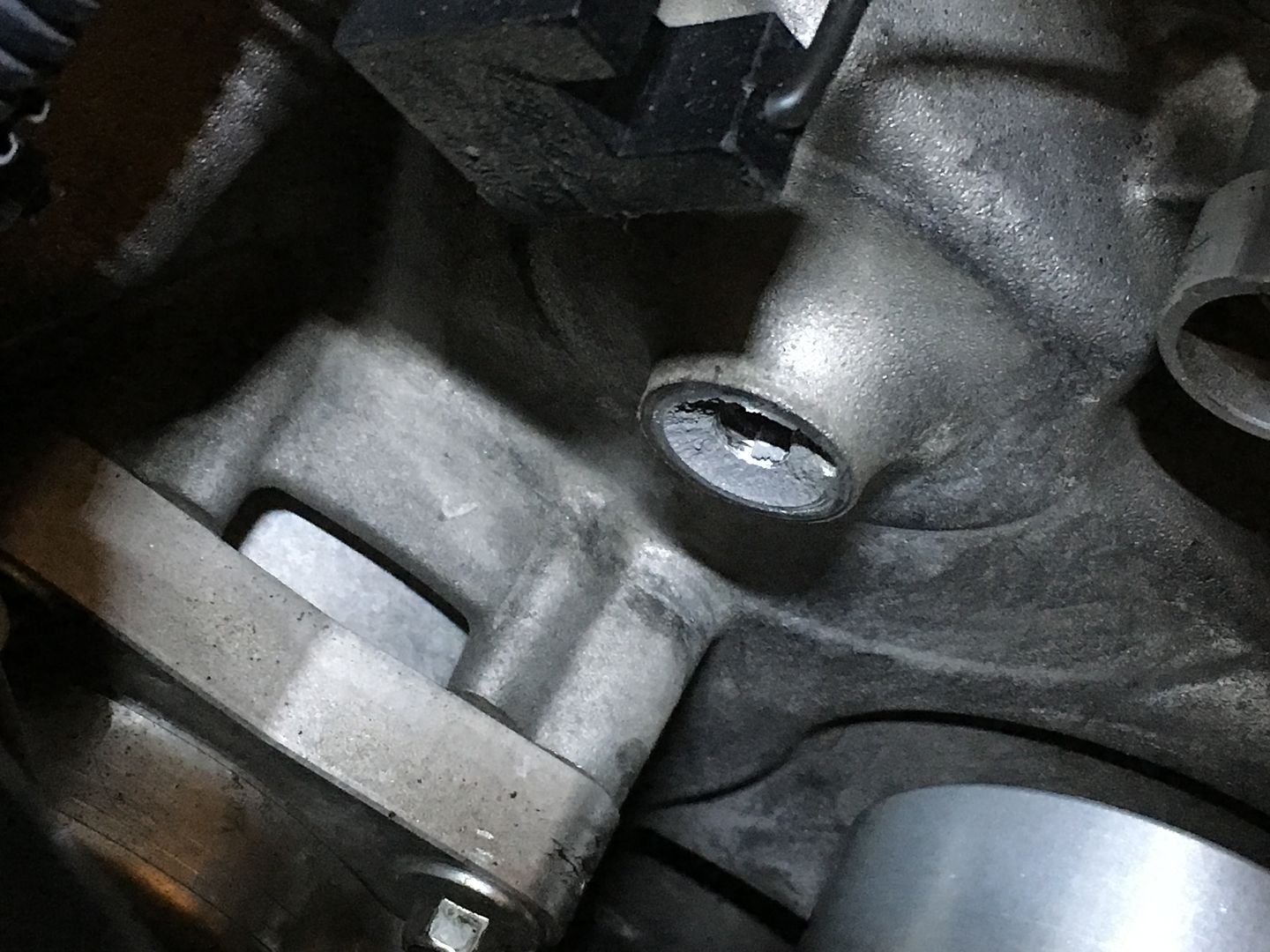

this happened because i put threadlock on it and it must of reacted adversely. The timing cover doesnt seem to be made out of metal, because where the pulley bolt seems to have pulled out{rather than snapped off} seems to be some sort of filler type material, almost like a bondo. anyways ill attach pic of the pulled out idler bolt and missing pulley.

engine still runs altho belt seems a bit loose, i drove 80 miles home. no overheating ?

question is: i wanna just thread a new bolt in there but as prior to this the idler pulley was loose and i couldnt get bolt to tighten i put a bit of threadlocker on it and this is what caused it to snap. Now do i just try to find the right size tap and tap the hole and put a new bolt in. Id rather not have to drill a size up and retap as i have no way to drill or even tap straight in or dont know how to do it straight. id just be doing it by eye if i retapped. What are my options for being a diyer but not a mechanic with measuring tools.

Sure enough my idler pulley the one that is right above the tensioner and to the right and just SEEMS TO JUST SLIGHTLY PUSH ON THE BELT A BIT TO INCREASE THE TENSION ON IT is on the ground, i couldnt find the bolt.

CARS STILL SEEMS TO RUN FINE ALTHO THE BELT SEEMS TO BE A BIT LOOSE.

this happened because i put threadlock on it and it must of reacted adversely. The timing cover doesnt seem to be made out of metal, because where the pulley bolt seems to have pulled out{rather than snapped off} seems to be some sort of filler type material, almost like a bondo. anyways ill attach pic of the pulled out idler bolt and missing pulley.

engine still runs altho belt seems a bit loose, i drove 80 miles home. no overheating ?

question is: i wanna just thread a new bolt in there but as prior to this the idler pulley was loose and i couldnt get bolt to tighten i put a bit of threadlocker on it and this is what caused it to snap. Now do i just try to find the right size tap and tap the hole and put a new bolt in. Id rather not have to drill a size up and retap as i have no way to drill or even tap straight in or dont know how to do it straight. id just be doing it by eye if i retapped. What are my options for being a diyer but not a mechanic with measuring tools.