I'm a little late to this party and have had a couple of Gen1 and now a Gen3 I'll give my 2cents worth.

If I were going to build any Coyote, I'd sleeve it with thick liners, deep six the total rotating assembly and go all forged. Yes, I know the factory crank is forged, but was never meant to handle 1000hp, 760hp, sure, but if you want a reliable 1000hp+ engine, do yourself a favor and use an aftermarket like Crower, Moldex, Bryant. Also throw the "Forged" OE rods as far as you can, or sell them, get some good rods that will not keep you awake at night, same with the pistons.

The Gen3 heads would be my choice as they flow almost as much as the CNC'd GT 350 heads.

The oil pump drive doesn't need to mentioned because it needs to be replaced even if you are shooting for a much lower number.

I've had a sub 10 second door slammer that was N/A and was impressed with my 19GT PP1/A10 turning 11.9's @ 117 in the quarter totally stock after 1/2 day of test and tune.

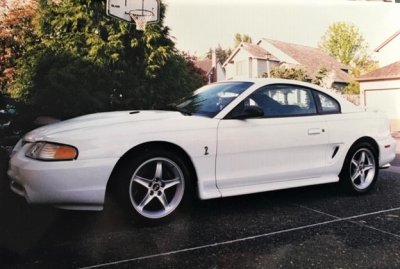

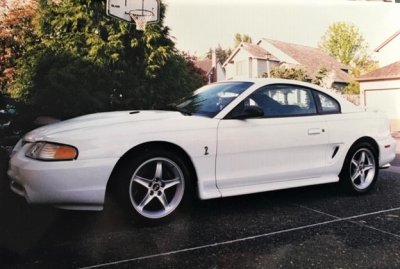

I put 12psi to my mostly stock 97 Cobra one time, any only lost a ring land, that's when I decided to go with an aftermarket rotating assembly that would withstand 15psi.

Like any engine you build, the attention to detail in machine work and mixing and matching the right parts will give you reliability. Sure you can use the stock crank and stock rods and cross your fingers every time you put your right foot to the floor, but for me...I don't want to have to even think about it because I know it was put together correctly and with best parts I could afford...do what you want because in the end it's your money.