To clarify the schematics, because it's a saddle tank with venturi siphon from passenger to driver side the passenger side of the tank empties first. There are 2 level sender floats one on each side. The boards on each read 15 ohms low to 160 ohms high and work independent and in tandem. The passenger side sender drives the gauge from full to 1/2 tank. And the driver side sender drives the gauge from 1/2 down to empty.

Because of this design the circuit can do funny stuff. You could disconnect one or the other and the remaining one would still drive the gauge properly in its respective half tank range.

However, if the siphon isn't working properly to empty passenger side first while driver side stays full or one sender is broken/shorted corroded that's when gauge readings can do weird stuff, fluctuate or not read correctly.

This is because the driver side should be at high 160 ohms the entire time the passenger side is traveling down from full 160 to empty 15 and gauge runs from full to half. Then once the p side is empty and that sender stays at full low 15. Then the driver side will start to run down from 160 as you go down from 1/2 tank towards empty.

Because of this tandem function if a sender on either side is not where it's reading should be when the other is traveling it will cause issues.

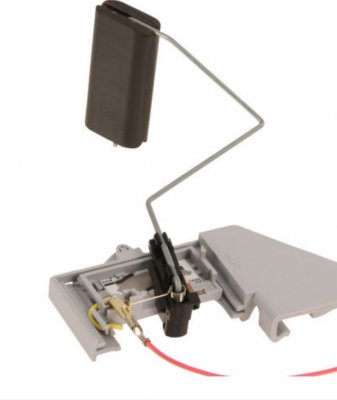

The way I troubleshoot senders is visual inspection of each. Clean the resistance boards, check for cracks, and occasionally resolder the wire point to the board as needed. Then manually bench test each float through travel and ensure the pick up arm maintains full contact with the board and then manually move and read resistance through the entire range. Once that's verified I reinstall and full fill up.

From there if both senders bench tested good and there are still issues, I suspect the stepper motor in the gauge cluster that drives the needle as it's a known problematic failure point.

Additionally to verify the siphon is good (as a bad siphon can cause bad readings). I wait until half tank or suspected half tank is reached and pop open the hats. I'm looking to make sure passenger side is completely empty and driver side is completed full.

Things I've seen: guys can kink or bend the internal line while doing a pump install. This can cause siphon issues leading to sender issues. Or not fully click it back on causing the same problem. Also guys bend crack or break senders during pump install. Sometimes they are just dirty and need cleaned. Lastly there is a bucket wall inside the tank on the driver side that the pump sits in and the sender arm needs to go outside the bucket wall towards the center of the car. I've seen the float jammed on the wrong side of the wall this is easy to do if fuel level is too low during install.

I've never got to the point of needing to check wiring back to the sjb and cluster from the senders.

05/06 specifically as of lately if no fuel work was done recently, its usually the stepper motor in the cluster failing. Occasionally its due to a dirty board or worn or corroded board wire connection.

Edit. I should add another issue is the resistance of the sender board changed in 2010. Guys sometimes mix up a 10-12 sender or gt500 hat onto a 05-09 car with the wrong sender.

A little history, stepper motor on dash replaced 10 years ago. Both hat assemblies are a couple of months old. Installed about a month apart. Passenger side is a Delphi, driver side is Walbro 400L fuel pump assembly. Both are E85 compatible. Installed a larger diameter fuel line also. They were tested before and after install. Gauge has worked in the past, (2 years) but was not accurate. Always shown more than was actually in tank.

Car doesn’t get a lot of miles but the the last 2-3 tankfuls, the gauge would stay between 1/2 and 3/4. Next to last fill up, the gauge went to 3/4 at pump, then slowly climbed to full during a 20 mile trip. I then drove enough to empty tank, and gauge never went below 1/2. When I filled it up, gauge went to 3/4.

Yesterday, while checking wires. I measured resistance at passenger side and it was at 52 ohms with a full tank. I pulled the hat, inspected things, bench tested sensor and everything was OK. Blew air through it crossover line and could hear bubbles on other side. Tested drivers side and that was at 142 ohms. I did not open drivers side. Reinstalled hat and had 162 ohms. Plugged wires in, turn on key, and gauge went to full. I put everything back together. I put 59 miles on the car this afternoon. Info center says I used 5.7 gallons. Gauge is closer to 3/4 than 1/2. Will put more miles on tomorrow and see what happens. Thanks.