I only have opinions, no direct experience and have seen no data on it.

Me: "Looks like a poorly designed part."

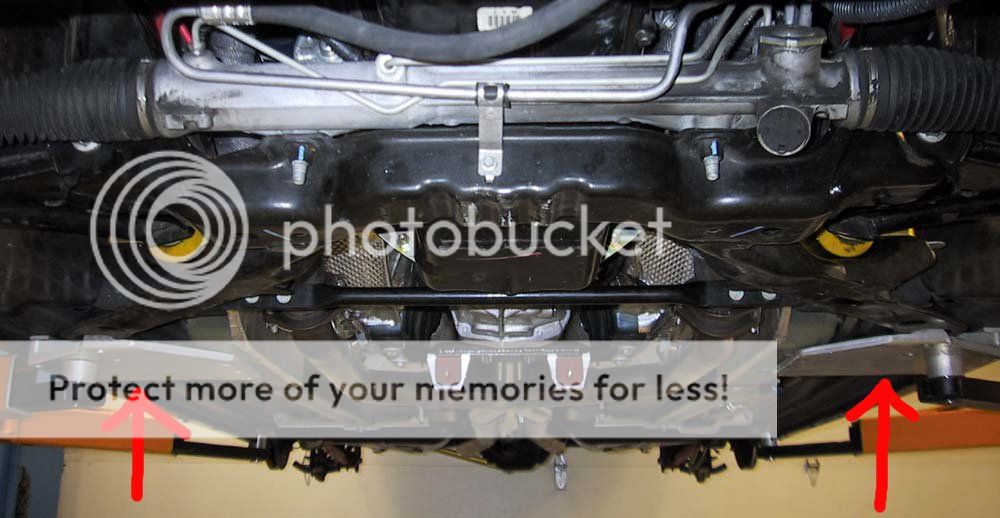

The purpose of the K-member braces out there (as well as Ford's OEM pieces) is to laterally brace the K-member. That's accomplished by some sort of laterally arranged rigid member. Thus, the left-to-right tubes you see for these. Hotchkis has this covered by the large plate at the top of their "X" (though I'd prefer to see a tube here rather than just a sheet of 1/8" steel that's been further compromised by cutting a logo into it). From the limited pics, it looks like there's a 90 deg bend here, so to my eyes you're talking about comparing a tubular brace to an angle-iron brace. I say tubular wins.

Then there's the rest of the brace, the "X" part. WTF is that supposed to accomplish? I think of these as resisting forces along the legs of the "X" and then wonder what sort of force that might be. Perhaps the strategy is to distribute loads from one side of the K-member to the other side as well as the trans tunnel. OK, I think I get that. It's still 1/8" sheet metal here, so all I see is flexing in these legs if there were real forces coming through them. I'd still prefer to see tube of some sort doing this job (think of a roll bars - would you like to see them made with flat sheet down bars while the builder is telling you, "oh yeah-yeah, I think those will hold").

Then there's "chassis flex" which I always associate with torsional rigidity. This is doing diddly for that. The X is in the wrong plane to resist torsional loads. So you're not going to get an appreciably more torsionally rigid chassis bolting this in place. Besides which, the S197 chassis is already plenty torsionally rigid for most folks who will ever own or even track these cars.

My $0.02

Best,

-j