redstangs9308gt

forum member

- Joined

- Dec 8, 2008

- Posts

- 1,251

- Reaction score

- 2

OK tomorrow I will take pics and you will have a better idea of everything.

I used regular mineral oil & wd-40 to make thick smoke. I would disconnect the air hose going to the air compressure put a little amount of oil in the canister, hook the hose back up and turn the power on to the glow plug and pump smoke through the vacuum hoses of the car. YOU MUST BLOCK OFF YOUR INTAKE EVERYTHING HAS TO BE SEALED UP OR THE PRESSURE WILL GO TO THE PLACE OF LEAST RESISTANCE.

This all started with

1985 f350 diesel glow plug 12volts Part number 1107 Autolite $9.99@AdvanceAuto

One metal pipe with threaded caps

One air hose fitting for air tools so you can hook to your air compressor (you must have a air pressure regular in line to reduce air pressure to around 10-20psi MAX with a cut off valve)

One transmission barbed fitting for 7/16th hose (going to T off into a vacuum line on your car)

One pressure gauge on your smoke machine to double check line pressure going to the vacuum hose. This will come in handy when keeping track of how much air pressure you are leaking off in a givin amount of time

I had to use a drill press to drill through the metal pipe and cap ends

I also had to buy threaders so I could just simply screw my glow plug, air chuck, gauge, and barbed fitting into the metal pipe.

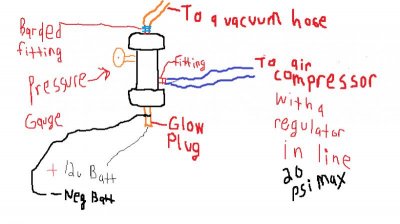

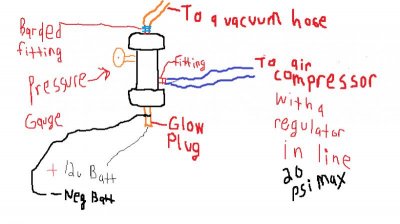

Here is a drawing. Hope this helps yall as much as it helped me today. It is as handy as a shirt pocket. SideNote you can google this and there is several different ways of going about making this work. This is just my idea of what would work best for me. Some guys used heating elements out of like a hot water heater. Some guys was getting oil residue in with there smoke and they had to make something to abstact the oil residue. Do your research and this will get you close.

I used regular mineral oil & wd-40 to make thick smoke. I would disconnect the air hose going to the air compressure put a little amount of oil in the canister, hook the hose back up and turn the power on to the glow plug and pump smoke through the vacuum hoses of the car. YOU MUST BLOCK OFF YOUR INTAKE EVERYTHING HAS TO BE SEALED UP OR THE PRESSURE WILL GO TO THE PLACE OF LEAST RESISTANCE.

This all started with

1985 f350 diesel glow plug 12volts Part number 1107 Autolite $9.99@AdvanceAuto

One metal pipe with threaded caps

One air hose fitting for air tools so you can hook to your air compressor (you must have a air pressure regular in line to reduce air pressure to around 10-20psi MAX with a cut off valve)

One transmission barbed fitting for 7/16th hose (going to T off into a vacuum line on your car)

One pressure gauge on your smoke machine to double check line pressure going to the vacuum hose. This will come in handy when keeping track of how much air pressure you are leaking off in a givin amount of time

I had to use a drill press to drill through the metal pipe and cap ends

I also had to buy threaders so I could just simply screw my glow plug, air chuck, gauge, and barbed fitting into the metal pipe.

Here is a drawing. Hope this helps yall as much as it helped me today. It is as handy as a shirt pocket. SideNote you can google this and there is several different ways of going about making this work. This is just my idea of what would work best for me. Some guys used heating elements out of like a hot water heater. Some guys was getting oil residue in with there smoke and they had to make something to abstact the oil residue. Do your research and this will get you close.

Last edited: