Using the floor jacks again the subframe connector was held in place making sure all contact points were flush with the frame. The subframe connector was tack welded in place at each of the four contact points. Jacks were lowered and the welds were finished.

Curtis my youngest daughter’s boyfriend hard at work.

Process was repeated for the Driver’s side. The fuel lines were insulated from the welding heat with damp rags where required.

The space under the car with my camera did not permit a full length installed picture.

All subframe connector and the chassis weld points were sprayed with Kyrlon Black Hammered like this.

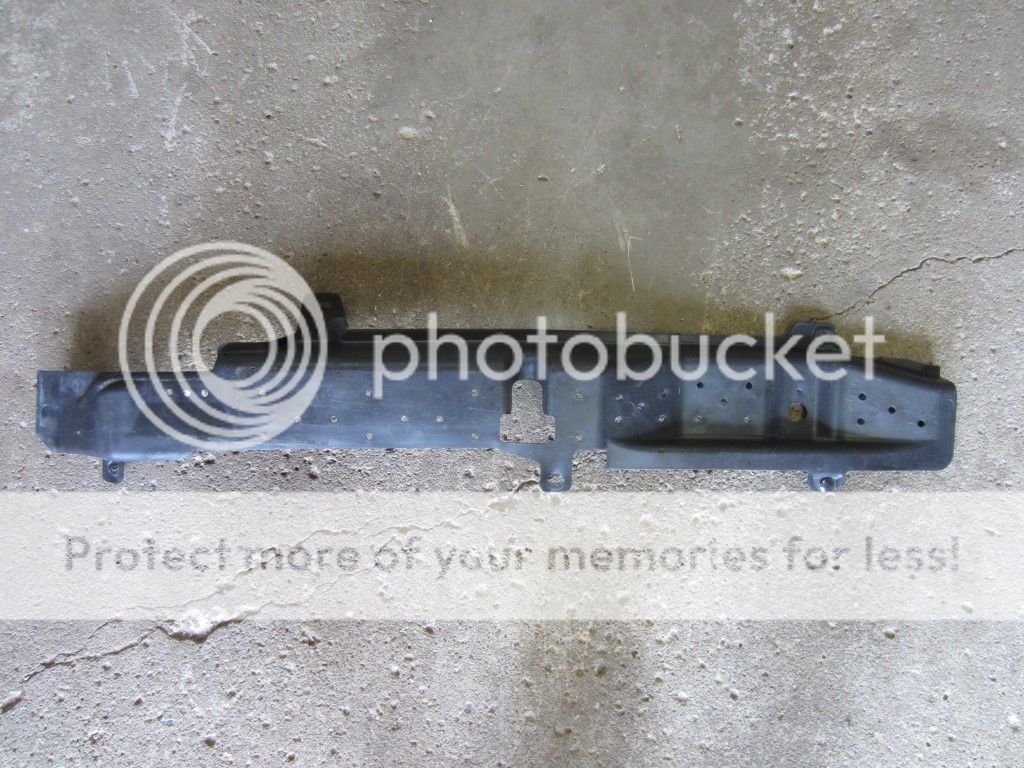

The plastic fuel line cover was sectioned into three pieces and the middle piece discarded. I cut the cover a little more complex than recommended in the BMR instructions to pick up an additional mounting point for the front cover.

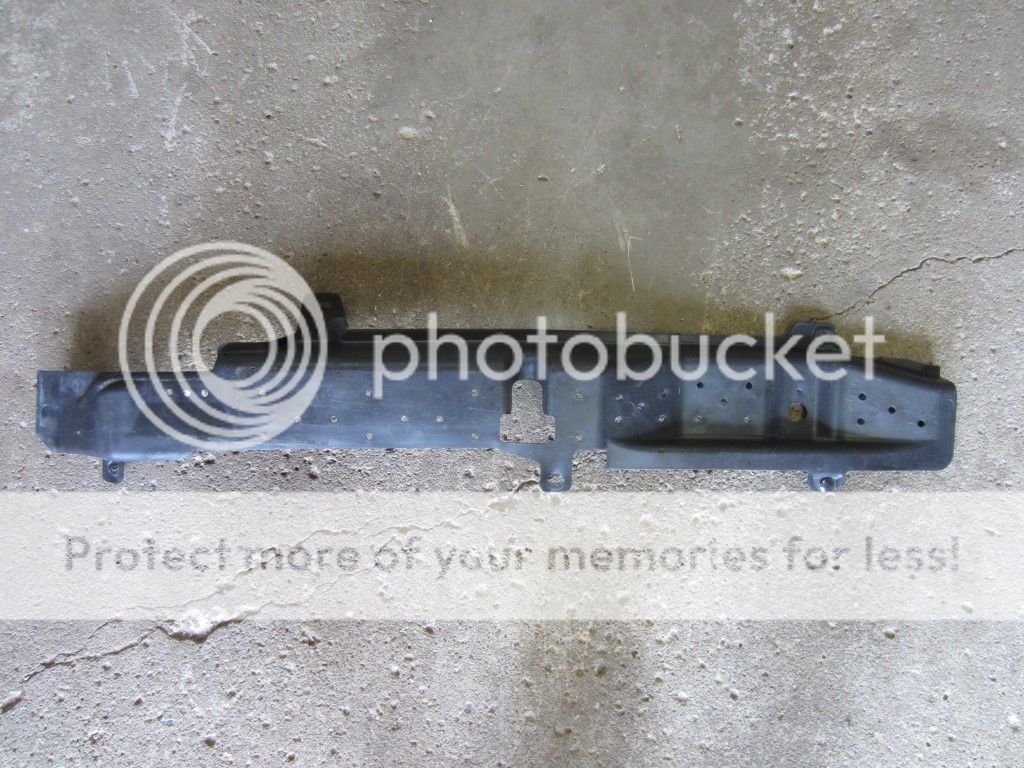

From the other direction showing the notch I made to retain the fastener mounting position.

Next up once the paint is dry the fuel covers and the parking brake cables go on.

Curtis my youngest daughter’s boyfriend hard at work.

Process was repeated for the Driver’s side. The fuel lines were insulated from the welding heat with damp rags where required.

The space under the car with my camera did not permit a full length installed picture.

All subframe connector and the chassis weld points were sprayed with Kyrlon Black Hammered like this.

The plastic fuel line cover was sectioned into three pieces and the middle piece discarded. I cut the cover a little more complex than recommended in the BMR instructions to pick up an additional mounting point for the front cover.

From the other direction showing the notch I made to retain the fastener mounting position.

Next up once the paint is dry the fuel covers and the parking brake cables go on.