continued from above

The last upgrade before Hallett was a simple set of rear lower tire spats. These are small little air deflectors that Ryan fabricated out of aluminum to smooth the transition from the flare to the side skirt, both visually and aerodynamically. He bent and welded this pair and made them attach to the back of the factory black plastic side skirt. These were painted black but the racing at Hallett took their toll on the finish (I shot the pics above

after Hallett), so these will come off and get a stronger semi-flat black powder coating before we go to SEMA. Like everything else, the finish of much the exterior of this car will need some touch-ups before its ready for the week long SEMA show or the televised Optima Ultimate Street Car Invitational event held immediately after in November.

The guys here at Vorshlag had everything prepped before Hallett in about a day. The brake pads and rotors looked great but they pushed a little fluid through anyway, to make sure it was bled. The Carbotech XP20 pads were brand new before the ECR test day and they swapped in fresh Carbotech pads out back halfway through the day there. Car was nut and bolted, I drove down to the local Shell to fill the tank with 93 octane (and we brought 20 gallons more with us, as Oklahoma only has 91 octane for premium), and a sticker set of Hoosier 335/345 tires were mounted. This was the winnings from TWS, and I

almost took a scrub set to Hallett and saved these.... but I got nervous at the last minute and had Olof mount the new sticker set.

Why? I was worried about two things: getting beat in TT3 at Hallett -or- maybe barely winning but not resetting our old track record there. My main TT3 competitor Jeff Tan had just had new aero installed front and back, new suspension spring rates added, and a stroker 2.3 liter motor drinking E85 in his red EVO 9. Our friends at

Evolution Dynamics had just put a new custom tune on Jeff's TT3 EVO that made 300whp from 3200rpm to 8000rpm, peaked at 326 whp and 410ft lbs of torque. In this much lighter car it could be a killer in this class. They use a boost trick to make constant "max power" across a huge rpm range, - and meets the letter of the TT rules. Nothing I can do about it except - build a similar turbo motor. Jeff was coming equipped for a battle! We also had 7 cars entered in TT3, including Boss302 driver John Scheier who I've known for 15 years and co-driven with at the Solo Nationals more than once. He's always fast. There were 10 cars in TT1, and I was worried about getting stuck behind some of the slower TT1 Corvettes if I didn't qualify well in the first TT practice session. And the 2013 TT3 National Champion was hinting on Facebook he

might show up at Hallett, so I had all sorts of threats looming.

The last mod we made was to my helmet - adding the D-ring hardware anchor mounts needed for the Simpson Hybrid Pro I was borrowing. I wanted to test this Simpson head and neck restraint system at Hallett, and the HANS quick-release post anchors I already had installed in my helmet were swapped out for these. No, you won't find these D-ring mounts at a local hardware store, like a friend told me, they

have to be special ordered. I got a pair from RaceDaySafety over-nighted after we struck out at all of the local race shops.

I have used a HANS branded device twice before (see above right) and absolutely hated the experience, so I was hoping the Simpson Hybrid Pro would work better for me - to actually allow me to turn my head, look down more than 1 degree while in the car and strapped in, etc. As an autocrosser I'm used to having my head on a swivel and looking way ahead, sometimes 90 degrees from the direction I'm traveling. I even autocross many times with an open faced helmet, for better visibility. The HANS I used back in 2012 was not a sliding tether style that allows you to rotate your head, so that was part of the misery. At Hallett there are a few corners where you

have to turn more than 90 degrees in a very short span of track, so looking out the side window to check and set-up corners would be crucial.

Still, I was determined to try to set a better example with my safety gear, vowing to run all of my sessions wearing my 3 layer suit, Nomex lined shoes and gloves; the Hybrid Pro attached and my Schroth 6-point belts secured tight. I was already sporting the back injury and this was my first event back, and I didn't want to make matters worse if I had a crash. Also, I was keeping an eye on the pain - if it got bad, I promised my wife Amy that I was going to hand off driving to my TT3 team mate (Amy). She wanted the seat time, too, so I had to watch my mouth and NOT complain unless it got really bad!

NASA at Hallett, June 21-22, 2014

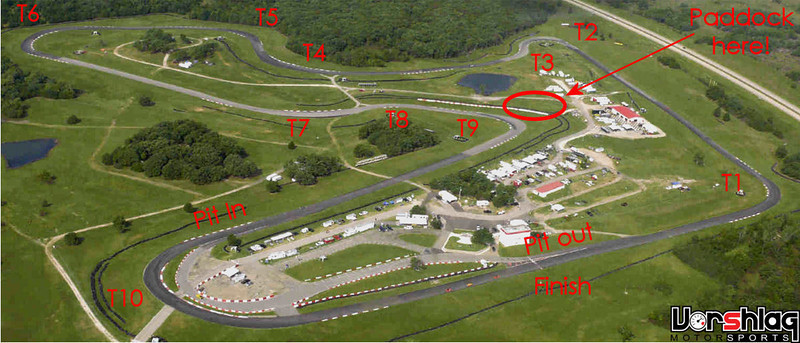

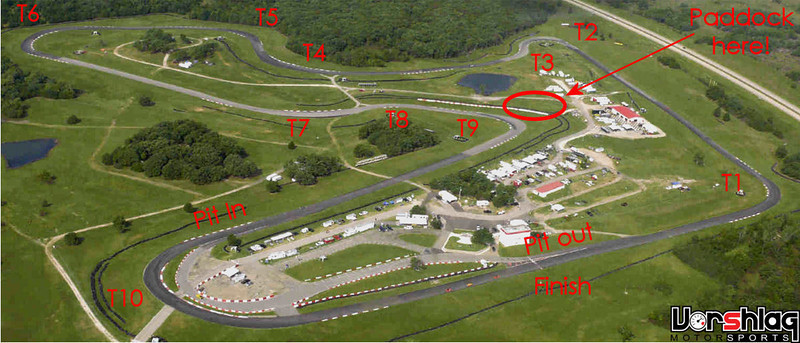

Amy didn't have enough time off from work to go up a day early and run the Friday test-n-tune. That's a shame, as we both needed the seat time at this track. I had run the CCW 1.8 mile Hallett circuit all of about 15 laps that one day in 2013, and Amy had no laps at all. My friend John and another buddy of his (and MCS customer of ours) Garrett arrived on Thursday night and had a good paddock spot set-up for us outside of Turn 9 (aka "The Bitch"). TT1 racer Marc Sherrin was also on site and paddocked with them by Friday morning and taking laps, and TTU racer Paul Costas was there as well in his GT-1 Camaro.

Vorshlag Event Picture Gallery: http://vorshlag.smugmug.com/Racing-Events/NASA-at-Hallett-062114/

Note - these pics are by me/Amy, Paul Costas, or Hallett's photographer (I bought a CD of pics)

We left Dallas plenty early at 2 pm, took our usual route north to Oklahoma City on I-35 and .... stopped. For an hour. There was massive construction traffic north of town that delayed our arrival by an hour, so we didn't get to the track until 7:30 pm. Luckily June 22nd is the longest day of the year so it was light until 9 pm, which allowed us plenty of time to unhook our trailer and... cart everyone to dinner 25 miles away. See, the Hallett Motor Racing Circuit is located in a remote part of rural Oklahoma and the nearest hotels are 25-35 miles away.

Marc had heard of some restaurant "on a lake" called Freddie's Steakhouse that was supposed to be good - and once we found it, it was actually pretty awesome. Amy and I were joined by racers Marc, Costas and HPDE director Scott for a solid 2 hour dinner where we laughed ourselves silly. Since we drove them to dinner we took another hour of driving to take most of them back to the track, then we went off in the opposite direction to our hotel in Sand Springs, 30 miles away. It made for a long day and late night but we had a good time.

Saturday June 21st - TT Day 1

Back at the track by 7 am Saturday morning and we quickly unloaded the Mustang. Finally saw John and Garrett from Colorado, who were paddocked next to us and Marc. We did some quick checks of the car, mounted the vidcam and AiM Solo DL, then went up to the club house for the TT meeting at 8 am. We had 44 TT cars entered, which made for a huge field. We were to go out together in the first TT Practice as a group but then the TT group was split into two groups for the rest of Saturday: TT1/2/3/U in one group and TTB-TTF in another.

There was ample coverage of the Passing Under Yellow issues we had at TWS and what was acceptable and what was not for this weekend. Dave B, Ken B and Scot Adams all put their foot down about PUY, not blocking, how to take a cool down lap without impeding, and where to safely pass at this track. It was a good meeting and I hope we can continue to have these open discussions amongst the TT drivers like this before each day of racing.

All 44 TT cars went out in the practice sessions with me driving and Amy riding shotgun. We were on the sticker set of Hoosiers with a plan to set an aggressive lap time and try to grid ahead of as many TT1 and TT2 cars as possible, to avoid traffic in later sessions. Amy has never driven this track before and I have only taken about 20 laps or so, so it was still a learning experience. Not to mention the radical changes we had made to the car since we raced here in 2013 - new aero, wider tires, new suspension and more weight.

This session started at 8:40 am, 77 degrees but humid, and I went out 3rd in grid (getting to grid early in these free-for-all first practice sessions is key!), behind Paul Costas TTU Camaro in front and Marc Sherrin's TT1 Corvette in 2nd. They both checked out and we were driving with a good gap in front and behind on the first lap. I was hoping I could show Amy a good line in this session without crashing, hitting a curb or going off track. Which did NOT happen, unfortunately! hehehe... I actually

did go off track at Turn 6 in the 2nd hot lap.

The TT Practice on Saturday is critical to get a good GRID PLACEMENT... which is why I was pushing so hard and went off, heh

The TT Practice on Saturday is critical to get a good GRID PLACEMENT... which is why I was pushing so hard and went off, heh

My first hot lap was a gentle 1:26 lap and then I was stepping it up in speed for lap two. We had the rear wing set at 12 degrees AoA which was a bit too much, and it was pushing at speed. There's also no more reference markers on track, as it had just been fully repaved about 6 weeks before. I turned in a little early in T6 and just got on the throttle a bit too early and just drove off the end of the turn. Not normally a big deal, as there's some smooth run-off here, but with the new paving there's a bit of a drop to the nicely mowed grass at the edge of the track and the "Drop" caught the leading edge of the splitter and pushed it back about 5 inches. Unbeknownst to me the splitter also acted as a mowing blade and gave the landscaping a closer cut, which packed up the lower grill's mesh with grass almost completely.

What's wrong about the picture above? The grill is PACKED full of grass! #fairslawnservice

What's wrong about the picture above? The grill is PACKED full of grass! #fairslawnservice

This cuts off all airflow to the radiator. Amazingly we finished that lap and one more before it started to run hot. I was exiting Turn 9 (The Bitch) on this 4th hot lap and I was catching the back of the TT1/2/3 field. As I crept up on a C5 Z06 I starting seeing spitting of water on the windshield. I made it around the final Turn T10 and on the front straight I looked down and saw the temp gauge starting to move quickly into the red. I was already past pit in and going 100+ so I shut off the motor and pulled offline, pointing everyone I had just passed back by me. Got around Turn 1 and there's no good place to pull off, so I briefly re-fired the motor, got around turns T2-T3 and pulled off, track right. By now the radiator cap had popped and it was gushing steam out of the hood vents and onto the windshield. I went off slowly enough not to damage the splitter further but it was pouring smoke and for a second there I thought it was actually on FIRE.

Saturday-Sunday's Hallett CCW track map. Ignore the "bunch up" and "go green" markers, which I royally screwed up on this version

Luckily it was just steam, but we had both already bailed out and the car was a good 50 yards off the track. We walked over behind a tire barrier and a corner worked came trotting over from Turn 4 to check on us, fire bottle in hand. I was wishing I had a bottle in the car at that very moment (more on that in a bit). I assured him we were OK and would stay behind the tire wall until the session ended, and that we didn't need a tow. I was just going to let it cool off, cleared the grill mesh of grass, and would limp it back to the paddock. While we were standing that the corner worker got a call on his radio and went running back to Turn 4. We couldn't see what had happened but as the cars went streaking by we noticed Jeff Tan's red TT3 EVO was missing....

One of our strongest TT3 competitors (Jeff) ended his day early with tire wall contact. Luckily this is a fully caged race car

One of our strongest TT3 competitors (Jeff) ended his day early with tire wall contact. Luckily this is a fully caged race car

Shortly after there were black flags at all corner stations and the workers at T3 waved us back on track as a pair of wreckers went racing to T4. We drove around and saw that Jeff's EVO had plowed straight off of T4, went through/over the tire barrier and through the catch fence, and it looked ugly. He was out of the car and looked OK but the car looked pretty tore up. The course workers and wrecker crew spent a while rebuilding the tire walls here, something we saw another 3 or 4 times this weekend. Since Hallett is built in the rolling hills amidst a lot of trees, they have tire walls and barriers on many corners which you don't want to find your way into. I got a series of pictures of a BMW that had an off in Turn 8 and took out a tire wall as well, shown above and below.

Boss302 entering Turn 9 (the Bitch) with the typical OEM suspension S197 brake dive

I was wearing my full driver suit, gloves, shoes and the Simpson Hybrid Pro during this full session and I was miserable, hot and soaking with sweat by the time we got back to the pits. I could not turn my head AT ALL using this Simpson and I generally hated wearing it. The D-rings were rattling and driving me nuts, and I tried wearing it again in 3 other sessions but it was so constricting that I couldn't see from T2 to T3 and it negatively impacted my driving each session I wore it. I also gave up on the driving suit by later that afternoon, as it got DAMNED HOT at Hallett and racing in this entry level 3-layer suit was unbearable. At another drivers meeting I noticed about a dozen of the TT drivers were using cool suits, even in only 3-4 lap blasts, and now I see why. And we just became a Coolshirt.com dealer, so now we might add one of these systems to our car... even after I said I'd never do that for TT. The heat and that damned suit was sapping the life out of me.

Hallett Eats Cars. I personally snapped pictures of these two cars destroying tire walls. With no run-off, that's what you tend to hit

Hallett Eats Cars. I personally snapped pictures of these two cars destroying tire walls. With no run-off, that's what you tend to hit

The front of Jeff's EVO is pretty much destroyed. That really sucks, but its another reminder of what can happen when you lose your brakes. Luckily ours worked great during that first session and the only failure was of my hack driving. We got to the pits and put about a gallon of water into the radiator and reservoir, then we thrashed on the car for an hour straight trying to fix the splitter. We had help from Patrick Lipsinic, Doug Worth, John and others. Time was running out and I was going to miss the next session if we didn't hurry, so we hooked up a strap to Doug's Raptor and pulled the splitter back into place.

continued below