TurboFocus

forum member

- Joined

- Jul 3, 2012

- Posts

- 249

- Reaction score

- 0

Well some know and some don't but I do a ton of welding and fabrication while I go to school full-time. Ive always done it out of my garage and worked on some pretty nasty stuff. I got started in turbos when I built my first turbo kit for my ford focus, after a couple years and a built engine it ended up making 454whp on pump and 602whp on race gas. This car taught me a lot of things and about two years ago I sold it for my mustang. After owning my mustang for 2 years I needed boost again so I decided to build my own kit. What was out on the market was ok to me but I like to put in the extra time and do new things that I've learned. So I bought all Tial products and and some Precision 6266CEA turbos, ordered a ton of material and went to town. Everything I do is by hand and I have the built not bought mentality.

Hellion owners read here lol:

Before we even get on to the pics, Yes I know the turbo placement and waste gate placement is nearly the same as the hellions kit, It is a really good spot and I liked it so I did the same placement, As far it goes that is all that is the same. Kinda the same way they every car manufacture puts 4 wheels on the corner of the car, because it works.

Now on to the pics.

Testing out the passenger side turbo placement and where I wanted it.

Then I moved on to the driver side trying to make them equal as possible even tho the fender wells are different. Also the Passenger had to be moved forward just a hair to make sure the headers would stay as symmetric as possible.

Didn't realize I only had one pic of the headers while they were in the tacking stage. But here is a pic of the driver side header just tacked up. The headers are made out of 14ga mild steel piping, contrary to popular belief mild steel holds up better to the extreme heat then stainless EXCEPT 321 which is very expensive.

Here is where I like to spend some extra time smoothing and finishing the merge collector area. All of the little details add up as you will see later

Started on the downpipes, they are 304 stainless steel that is back purged when I weld them. This pic is before the waste gate dumps. They are Vbanded to the turbo and use factory style eurojoints on the rear to connect to the H-Pipe.

Weld shot

Making the Wastegate dump tube. Im using an 1.5in Inconel flex bellow to help with expansion between the pipes.

Here is an inside shot of the waste gate dump, you can see it has been smoothed and has a nice fit up. the next pic you can see the back purging on the inside.

After all of the Hotside was done I ceramic coated the parts grey. I do all my own ceramic coating in-house also, found the company while I was at the SEMA show.

After the Ceramic coating was done I powder coated the compressor housings texture black, yes I do this in-house also lol.

Moving on to the intercooler, I bought a intercooler core and built my own end tanks. I used a very large core that is rated for 1300hp. This core is 4in thick and proves to be a great core.

Making the bottom endtanks

Its all in the details. Radiused and blending the end tanks.

Now on to the top end tank. I wanted to run 3.5 piping from the intercooler to the throttle body with no restrictions. I formed and blended the 3.5in pipe to mate directly to the end tank.

Here is the intercooler piping. I wanted to run the MAF in the 3.5 pipe to keep the maf signal as clear as possible.

Here is a shot of the intercooler piping and I moved the ECU.

Random weld shot

A pic of the BOV smoothed and blended.

Random pics

Catchcan setup I made since I had to move my old one to make room for the fuel system.

Fuel regulator and 2step box mount, sorry its so blurry.

Swapping rear ends with my dad. He had 3:31 Gears and I had 3:73 so we swapped since i would need 3:31s

Completed pics of the setup

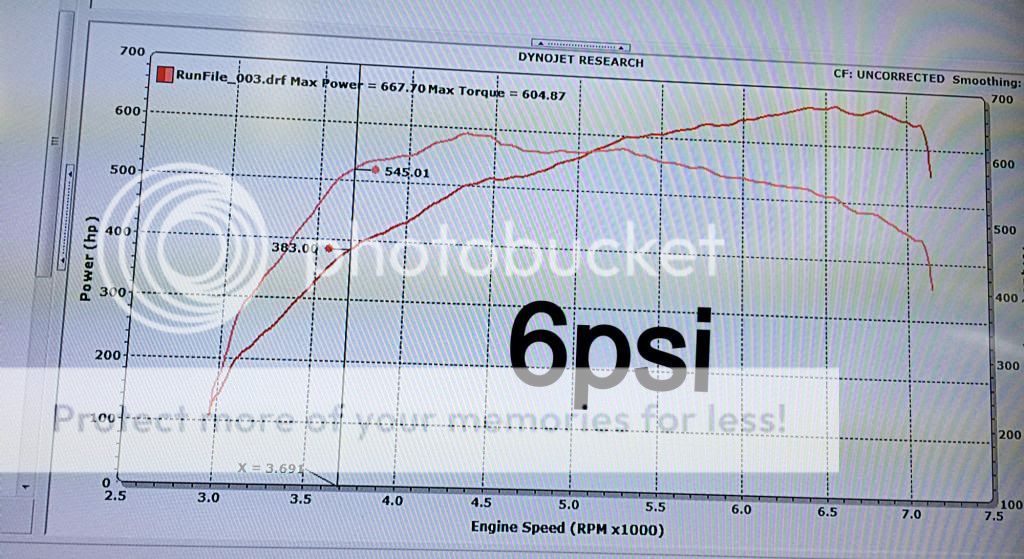

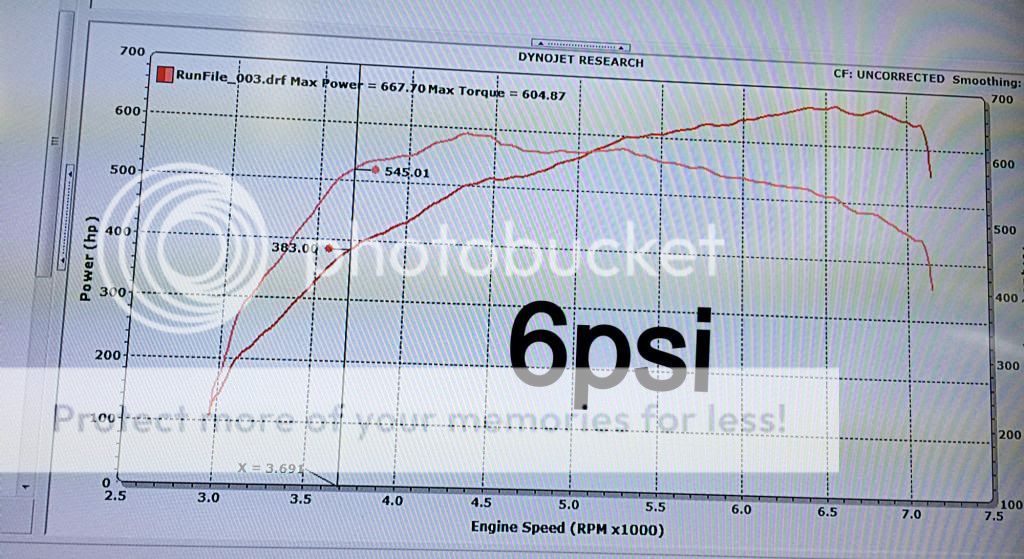

So My whole goal with this build was to make the post power per lb. possible without going to the extreme. So I put the 4psi spring in the car and my Buddy Sai started tuning it. After multiple street pulls he had the tune where he wanted it. 4psi felt good but it just didn't feel crazy fast or anything. So a week later we set a appointment for the dyno, we agree to put the 7.8psi (which made exactly 8psi)springs in because we felt thats what it would take to make 650ish RWHP. The dyno we use is a DynoJet 248x, This is a big roller dyno. We strap it down on the dyno and make our first pull, AFR, timing, etc looked great. actually timing was a little on the low side for 8psi. When we looked at the screen we were all astonished the dyno read 741RWHP, this is a completely bone stock motor and mt82 trans. We were super happy it made those numbers on that boost but again it being a stock motor I didn't want to push it. So I changed out the 7.8 springs for the 5.8psi spring, and we made another pull. Check the dyno readings and it made 667RWP uncorrected and 677RWHP STD correction (I see a lot of ppl post on here lol) The boost peaked at 6psi on the dot. After the dyno session it felt great to know that all the extra things I did to the turbo kit paid off. The car is extremely fun to drive on 6psi, but I deff need drag radials for the street, getting really sideways in 3rd is not fun. I want to thank Sai for spending hours on tuning this car over multiple days.

Here are the graphs

Dyno Vid

Hellion owners read here lol:

Before we even get on to the pics, Yes I know the turbo placement and waste gate placement is nearly the same as the hellions kit, It is a really good spot and I liked it so I did the same placement, As far it goes that is all that is the same. Kinda the same way they every car manufacture puts 4 wheels on the corner of the car, because it works.

Now on to the pics.

Testing out the passenger side turbo placement and where I wanted it.

Then I moved on to the driver side trying to make them equal as possible even tho the fender wells are different. Also the Passenger had to be moved forward just a hair to make sure the headers would stay as symmetric as possible.

Didn't realize I only had one pic of the headers while they were in the tacking stage. But here is a pic of the driver side header just tacked up. The headers are made out of 14ga mild steel piping, contrary to popular belief mild steel holds up better to the extreme heat then stainless EXCEPT 321 which is very expensive.

Here is where I like to spend some extra time smoothing and finishing the merge collector area. All of the little details add up as you will see later

Started on the downpipes, they are 304 stainless steel that is back purged when I weld them. This pic is before the waste gate dumps. They are Vbanded to the turbo and use factory style eurojoints on the rear to connect to the H-Pipe.

Weld shot

Making the Wastegate dump tube. Im using an 1.5in Inconel flex bellow to help with expansion between the pipes.

Here is an inside shot of the waste gate dump, you can see it has been smoothed and has a nice fit up. the next pic you can see the back purging on the inside.

After all of the Hotside was done I ceramic coated the parts grey. I do all my own ceramic coating in-house also, found the company while I was at the SEMA show.

After the Ceramic coating was done I powder coated the compressor housings texture black, yes I do this in-house also lol.

Moving on to the intercooler, I bought a intercooler core and built my own end tanks. I used a very large core that is rated for 1300hp. This core is 4in thick and proves to be a great core.

Making the bottom endtanks

Its all in the details. Radiused and blending the end tanks.

Now on to the top end tank. I wanted to run 3.5 piping from the intercooler to the throttle body with no restrictions. I formed and blended the 3.5in pipe to mate directly to the end tank.

Here is the intercooler piping. I wanted to run the MAF in the 3.5 pipe to keep the maf signal as clear as possible.

Here is a shot of the intercooler piping and I moved the ECU.

Random weld shot

A pic of the BOV smoothed and blended.

Random pics

Catchcan setup I made since I had to move my old one to make room for the fuel system.

Fuel regulator and 2step box mount, sorry its so blurry.

Swapping rear ends with my dad. He had 3:31 Gears and I had 3:73 so we swapped since i would need 3:31s

Completed pics of the setup

So My whole goal with this build was to make the post power per lb. possible without going to the extreme. So I put the 4psi spring in the car and my Buddy Sai started tuning it. After multiple street pulls he had the tune where he wanted it. 4psi felt good but it just didn't feel crazy fast or anything. So a week later we set a appointment for the dyno, we agree to put the 7.8psi (which made exactly 8psi)springs in because we felt thats what it would take to make 650ish RWHP. The dyno we use is a DynoJet 248x, This is a big roller dyno. We strap it down on the dyno and make our first pull, AFR, timing, etc looked great. actually timing was a little on the low side for 8psi. When we looked at the screen we were all astonished the dyno read 741RWHP, this is a completely bone stock motor and mt82 trans. We were super happy it made those numbers on that boost but again it being a stock motor I didn't want to push it. So I changed out the 7.8 springs for the 5.8psi spring, and we made another pull. Check the dyno readings and it made 667RWP uncorrected and 677RWHP STD correction (I see a lot of ppl post on here lol) The boost peaked at 6psi on the dot. After the dyno session it felt great to know that all the extra things I did to the turbo kit paid off. The car is extremely fun to drive on 6psi, but I deff need drag radials for the street, getting really sideways in 3rd is not fun. I want to thank Sai for spending hours on tuning this car over multiple days.

Here are the graphs

Dyno Vid