I will be running these in mine so wanted to read up on the company.

Thought I would share this information with the rest of you.

Choosing The Right Fuel Injector For Your Mustang With DeatschWerks

By Don Creason

posted on Mar 7, 2014 in Fuel & Cooling

http://www.stangtv.com/tech-stories...-injector-for-your-mustang-with-deatschwerks/

Multi-port fuel injection made it’s debut on Mustangs around 30 years ago,

with the four-cylinder turbo SVO. This modern fuel injection system didn’t

make it to the V8 5.0 until 1986, when some old-school enthusiasts decried

that it was the death of modern performance. It wouldn’t take long for

many to figure out that fuel injected Mustangs were as potent, if not more

so than their carbureted predecessors.

While MPFI has been around for decades now, there is still some confusion,

and many misconceptions about fuel injection, specifically surrounding fuel

injectors. For instance how do you know what fuel injector size your

specific car needs? How do you maximize the performance of those fuel

injectors? And what are some of the differences between the different

types, styles, etc.

Not all injectors are equal, and choosing the right one is critical to power production, and drivability in any build.

To answer these questions, and many more we spent some time with David

Deatsch, president of DeatschWerks. DeatschWerks (DW) spent the last

10 years carving out a niche for building high quality fuel injectors for the

sport-compact performance market. In recent years they’ve expanded into

the modern muscle car market, and offer an array of injector products and

services to suit the needs of a variety of builds from mild or near stock

street cars, to 2,000 horsepower drag strip beasts.

When Do You Need Injectors

Personalization and performance are hallmarks of owning a Mustang or any

other performance car. When it comes to the car’s fuel injectors however

, replacing them under the assumption that doing so will net better

performance is a common misconception. According to Deatsch, “Until the

original equipment injectors can no longer provide the fuel for the power

your engine makes you don’t need to replace them.”

At the OE level, powertrain engineers spend countless hours agonizing over

each component, including fuel injectors to give a vehicle the most

performance possible. This makes those OE parts the best option until they

either encounter a failure, or are no longer providing the proper fuel supply

for the current upgrades. DW offers several online calculators to help

enthusiasts determine what injectors they need.

One exception to this rule would be when making an upgrade in fuel

injector technology. For example taking a Fox body Mustang equipped with

older Bosch EV1 style fuel injectors, and upgrading it to Bosch EV14

. Deatsch says this will improve performance and reliability, “EV14

represents the latest technology in MPFI. These injectors offer the highest

reliability, fastest response, and greatest atomization. DW utilizes EV14

exclusively in their Mustang injector line-up.”

Quote:

selecting the correct fuel injectors and fuel system components.

Understanding IDC

A key factor in fuel injector performance is injector duty cycle (IDC). IDC is

the amount of time that a fuel injector is on or open. For example an IDC

of 50-percent means that 50% of the time, the injectors are open and

spraying fuel. Deatsch recommends data logging the IDC to determine if

replacement is required. If the injectors are at or exceeding 80-90-percent

then it’s time to upgrade to a larger injector.

Deatsch recommends slightly lower duty cycles in racing applications than

in street applications. This is largely due to the fact that most racing

engine fuel injectors will spend the majority of their life operating at a high

duty cycle. 80-percent on racing engines is also ideal because it leaves

tuners and race teams a margin to grow in, meaning if they want to

increase the power before the next round or race by getting more

aggressive on their setup, they may be able to do so without worrying

about the ability of the fuel injectors to keep up.

The calculators on the DW site can be used not only to determine

what injector should fit a particular application but also the flow rate

of that injector, how changing fuel pressure affects it, and what type

of fuel pump is needed to feed the combination.

In street applications IDC of 80-90-percent is the suggested cutoff for a

variety of reasons. First off, excessively high duty cycles create a lot of

heat in both the injector coils and injector drivers. Over a period of time,

this heat can cause premature failure of both of these components

. Secondly, injectors do not operate as consistently at high duty cycles.

Usually somewhere between 93-97% injectors will begin to “go static”

meaning they will intermittently fail to close between injection events. This

will cause unpredictable, excessive fuel delivery and subsequently unstable

air-fuel ratios. In short, keeping your IDC below 80-90% will improve

reliability of your fuel system, maximize its performance, and give you a

little headroom for over boosting or adding more power later down the

road.

Deciding Factors

In the mid to late 1990’s most Mustang enthusiasts typically opened up a

Ford Racing catalog and picked their injectors by going one or two sizes

up. While that often worked back then, we have a wider array of tools,

and knowledge about fuel injection than was available 20 years ago.

In addition to IDC a number of other factors that play into selecting the

proper injectors include:

"We highly suggest that you avoid “universal” injectors unless you

have a very real reason not to."

Number of cylinders:

A four or six cylinder engine that makes 400 horsepower, will need more

fuel per cylinder to create that horsepower than a V8 making the same

power.

Fuel Pressure:

Older Mustang EFI systems often operated at 39 psi as their base

pressure. The current Coyote engines utilize a 58 psi fuel system.

According to Deatsch, “The higher the fuel pressure the more fuel you can

squeeze out of an injector.” So a higher pressure system may utilize a

slightly smaller fuel injector than a lower pressure system on an engine of

the same horsepower if the fuel system is properly designed.

BSFC:

Brake specific fuel consumption is a measurement of how efficient an

engine is. This in turn effects how much fuel that engine needs to operate

properly. According to Deatsch naturally aspirated engines have a better

(lower) BSFC than a forced induction engine. This efficiency means that a

NA engine will typically require smaller fuel injectors than a forced induction

engine making similar power levels.

Although they put down similar power numbers when they were new

off the assembly line, the SVO engine (left) requires larger injectors

than the 5.0 MPFI engine that only makes a few horsepower

Fuel Type

Racers have a wider choice of fuels than ever before. Race fuel like VP’s

C16 requires less fuel volume to make power than an oxygenated fuel like

their Q16, and far less volume than an Ethanol fuel, which can require

30-percent more volume than race gas.

Spacers, different O-rings, and electrical adapters can add up costs if

an injector is not truly a drop in fitment.

The Right Fit

True drop-in fitment is another area where DW takes a lot of pride in what

they do. Fitment is not only ensuring that the injector body is the same

length from O-ring to O-ring, but that the electrical connections are the

same, or that the injectors will fit into the intake manifold and into the fuel

rail. It also includes ensuring the injector spray pattern is matched to a

specific application, and that the injector is compatible at all levels with

the engine and electronics being used.

“We highly suggest that you avoid “universal” injectors unless you have a

very real reason not to. Universal injector will often require additional and

sometimes expensive fitment “accessories” electrical connectors alone can

cost $10-$15 each. Fuel rails, fuel rail spacers, o-rings, sometimes even a

new manifold is required to fit a universal injector.”

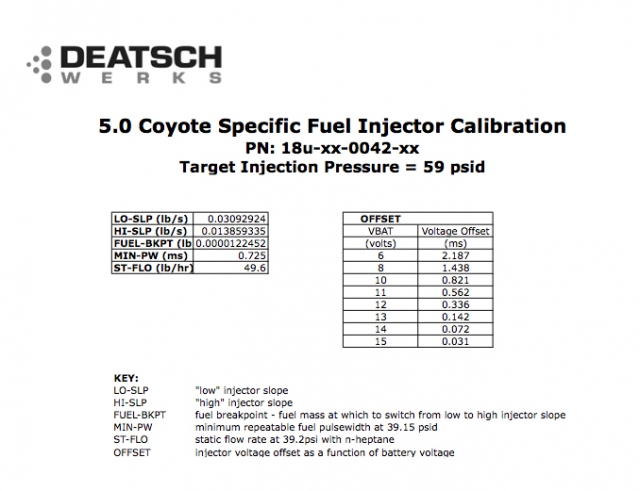

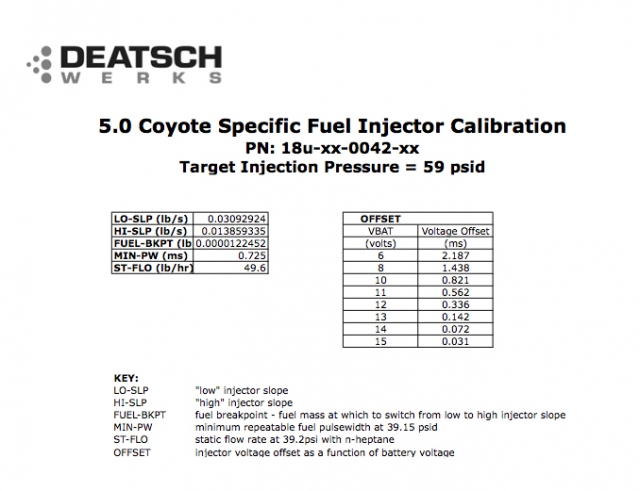

Tuning

Tuning is the final piece of the puzzle in the critical process of getting the

right fuel injectors. In the past several years tuning data has become more

readily available from injector companies. Calibration summaries and

injector data are available for every Mustang injector that DW sells, and

they develop this data in-house.

New products undergo extensive flow testing to gather this data and

formulate a proper injector characterization. The data is then formatted

specifically for each application and validated in-car on a dyno. All of this

is done before being sold to customers. “Keeping it simple for the user is

key. Customers and tuners can go to the resources page of the DW

website, look up their particular set of injectors, and literally cut and paste

the tuning data for the fuel injector tables directly into their tuning

software,” says Deatsch.

This single piece of data, provided with every set of Mustang

injectors from DeatschWerks, can potentially save tuners hours in

custom tuning work, and owners hundreds of dollars.

With Mustangs the data needed to tune includes:

Fully Balanced

matched set of injectors.

DW has developed a proprietary system for flow-balancing known as

Multi-Point Dynamic Flow Balancing (MPDFB). In the past, injectors were

typically tested using static balancing. This process ran the injectors

wide-open “static” for a set amount of time. Each injector sprayed liquid

into a graduated cylinder during that cycle, and the numbers from each

were then compared. Injectors were then typically grouped together in

sets that had similar “static” flow rates.

The trouble is that fuel injectors are not static fuel metering devices. “Fuel

injectors are very dynamic components, constantly opening and closing

multiple times per second,” syas Deatsch. This is why he says that DW

developed their (MPDFB) system. “This type of flow balancing quantifies

the fuel delivery of each injector across the full range of pulsewidths

injectors operate in the car. This includes a low, or start condition pulse

width, idle pulse width, mild acceleration pulse width, and high, or full

throttle level pulse widths.”

A DW technician prepares a set of injectors for flow balancing.

Left: Injector balancing is performed using graduated cylinders.

Injectors are then run over a variety of duty cycles to check their

flow rates. This set is not balanced due to the large discrepancy

between their flow numbers. Right: This set of injectors is considered

balanced because their flow is very closely matched, meaning they

will deliver consistent fuel delivery across all cylinders.

The MPDFB process could be compared to blueprinting an engine or looking

at the area under the curve on a dyno graph. All of the data is recorded

and compared, and each injector is scribed with an identifying number so it

can easily be referenced. By doing this injectors can be precisely matched

as a set, ensuring consistent performance at full throttle, and stock-like

starts, idle quality, and drivability in all other driving situations.

Quality And Service

EV1, EV14, GDI, and more. DeatschWerks can provide Mustang

owners with the right injector for their engine.

The last area to look at when selecting a set of injectors for any

performance application is the quality of the product and the customer

service. That guy selling “refurbished” injectors on eBay is likely not going

to give the time of day if or when there’s a problem with installation or

tuning. Having a company that is easily accessible and eager to help their

customers creates a kind of partnership through that level of service, and

is paramount to getting any project car set up properly.

According to Deatsch all of the factors we’ve discussed in this article are

critical in creating a good product, but customer service is also a key at

DW. Getting tech support to choose injectors before the sale, and then

helping with tuning, or trouble shooting after the fact is something

DeatschWerks prides themselves in, along with their extensive R&D process

and injector services.

Sources

Deatschwerks

Terry

Call

Send SMS

Add to Skype

You'll need Skype CreditFree via Skype

Thought I would share this information with the rest of you.

Choosing The Right Fuel Injector For Your Mustang With DeatschWerks

By Don Creason

posted on Mar 7, 2014 in Fuel & Cooling

http://www.stangtv.com/tech-stories...-injector-for-your-mustang-with-deatschwerks/

Multi-port fuel injection made it’s debut on Mustangs around 30 years ago,

with the four-cylinder turbo SVO. This modern fuel injection system didn’t

make it to the V8 5.0 until 1986, when some old-school enthusiasts decried

that it was the death of modern performance. It wouldn’t take long for

many to figure out that fuel injected Mustangs were as potent, if not more

so than their carbureted predecessors.

While MPFI has been around for decades now, there is still some confusion,

and many misconceptions about fuel injection, specifically surrounding fuel

injectors. For instance how do you know what fuel injector size your

specific car needs? How do you maximize the performance of those fuel

injectors? And what are some of the differences between the different

types, styles, etc.

Not all injectors are equal, and choosing the right one is critical to power production, and drivability in any build.

To answer these questions, and many more we spent some time with David

Deatsch, president of DeatschWerks. DeatschWerks (DW) spent the last

10 years carving out a niche for building high quality fuel injectors for the

sport-compact performance market. In recent years they’ve expanded into

the modern muscle car market, and offer an array of injector products and

services to suit the needs of a variety of builds from mild or near stock

street cars, to 2,000 horsepower drag strip beasts.

When Do You Need Injectors

Personalization and performance are hallmarks of owning a Mustang or any

other performance car. When it comes to the car’s fuel injectors however

, replacing them under the assumption that doing so will net better

performance is a common misconception. According to Deatsch, “Until the

original equipment injectors can no longer provide the fuel for the power

your engine makes you don’t need to replace them.”

At the OE level, powertrain engineers spend countless hours agonizing over

each component, including fuel injectors to give a vehicle the most

performance possible. This makes those OE parts the best option until they

either encounter a failure, or are no longer providing the proper fuel supply

for the current upgrades. DW offers several online calculators to help

enthusiasts determine what injectors they need.

One exception to this rule would be when making an upgrade in fuel

injector technology. For example taking a Fox body Mustang equipped with

older Bosch EV1 style fuel injectors, and upgrading it to Bosch EV14

. Deatsch says this will improve performance and reliability, “EV14

represents the latest technology in MPFI. These injectors offer the highest

reliability, fastest response, and greatest atomization. DW utilizes EV14

exclusively in their Mustang injector line-up.”

Quote:

DeatschWerks offers a variety of online calculators to aide inEV14 represents the latest technology in MPFI. These injectors offer the

highest reliability, fastest response, and greatest atomization. DW utilizes

EV14 exclusively in their Mustang injector line-up. -David Deatsch

, DeatschWerks

selecting the correct fuel injectors and fuel system components.

Understanding IDC

A key factor in fuel injector performance is injector duty cycle (IDC). IDC is

the amount of time that a fuel injector is on or open. For example an IDC

of 50-percent means that 50% of the time, the injectors are open and

spraying fuel. Deatsch recommends data logging the IDC to determine if

replacement is required. If the injectors are at or exceeding 80-90-percent

then it’s time to upgrade to a larger injector.

Deatsch recommends slightly lower duty cycles in racing applications than

in street applications. This is largely due to the fact that most racing

engine fuel injectors will spend the majority of their life operating at a high

duty cycle. 80-percent on racing engines is also ideal because it leaves

tuners and race teams a margin to grow in, meaning if they want to

increase the power before the next round or race by getting more

aggressive on their setup, they may be able to do so without worrying

about the ability of the fuel injectors to keep up.

The calculators on the DW site can be used not only to determine

what injector should fit a particular application but also the flow rate

of that injector, how changing fuel pressure affects it, and what type

of fuel pump is needed to feed the combination.

In street applications IDC of 80-90-percent is the suggested cutoff for a

variety of reasons. First off, excessively high duty cycles create a lot of

heat in both the injector coils and injector drivers. Over a period of time,

this heat can cause premature failure of both of these components

. Secondly, injectors do not operate as consistently at high duty cycles.

Usually somewhere between 93-97% injectors will begin to “go static”

meaning they will intermittently fail to close between injection events. This

will cause unpredictable, excessive fuel delivery and subsequently unstable

air-fuel ratios. In short, keeping your IDC below 80-90% will improve

reliability of your fuel system, maximize its performance, and give you a

little headroom for over boosting or adding more power later down the

road.

Deciding Factors

In the mid to late 1990’s most Mustang enthusiasts typically opened up a

Ford Racing catalog and picked their injectors by going one or two sizes

up. While that often worked back then, we have a wider array of tools,

and knowledge about fuel injection than was available 20 years ago.

In addition to IDC a number of other factors that play into selecting the

proper injectors include:

"We highly suggest that you avoid “universal” injectors unless you

have a very real reason not to."

Number of cylinders:

A four or six cylinder engine that makes 400 horsepower, will need more

fuel per cylinder to create that horsepower than a V8 making the same

power.

Fuel Pressure:

Older Mustang EFI systems often operated at 39 psi as their base

pressure. The current Coyote engines utilize a 58 psi fuel system.

According to Deatsch, “The higher the fuel pressure the more fuel you can

squeeze out of an injector.” So a higher pressure system may utilize a

slightly smaller fuel injector than a lower pressure system on an engine of

the same horsepower if the fuel system is properly designed.

BSFC:

Brake specific fuel consumption is a measurement of how efficient an

engine is. This in turn effects how much fuel that engine needs to operate

properly. According to Deatsch naturally aspirated engines have a better

(lower) BSFC than a forced induction engine. This efficiency means that a

NA engine will typically require smaller fuel injectors than a forced induction

engine making similar power levels.

Although they put down similar power numbers when they were new

off the assembly line, the SVO engine (left) requires larger injectors

than the 5.0 MPFI engine that only makes a few horsepower

Fuel Type

Racers have a wider choice of fuels than ever before. Race fuel like VP’s

C16 requires less fuel volume to make power than an oxygenated fuel like

their Q16, and far less volume than an Ethanol fuel, which can require

30-percent more volume than race gas.

Spacers, different O-rings, and electrical adapters can add up costs if

an injector is not truly a drop in fitment.

The Right Fit

True drop-in fitment is another area where DW takes a lot of pride in what

they do. Fitment is not only ensuring that the injector body is the same

length from O-ring to O-ring, but that the electrical connections are the

same, or that the injectors will fit into the intake manifold and into the fuel

rail. It also includes ensuring the injector spray pattern is matched to a

specific application, and that the injector is compatible at all levels with

the engine and electronics being used.

“We highly suggest that you avoid “universal” injectors unless you have a

very real reason not to. Universal injector will often require additional and

sometimes expensive fitment “accessories” electrical connectors alone can

cost $10-$15 each. Fuel rails, fuel rail spacers, o-rings, sometimes even a

new manifold is required to fit a universal injector.”

Tuning

Tuning is the final piece of the puzzle in the critical process of getting the

right fuel injectors. In the past several years tuning data has become more

readily available from injector companies. Calibration summaries and

injector data are available for every Mustang injector that DW sells, and

they develop this data in-house.

New products undergo extensive flow testing to gather this data and

formulate a proper injector characterization. The data is then formatted

specifically for each application and validated in-car on a dyno. All of this

is done before being sold to customers. “Keeping it simple for the user is

key. Customers and tuners can go to the resources page of the DW

website, look up their particular set of injectors, and literally cut and paste

the tuning data for the fuel injector tables directly into their tuning

software,” says Deatsch.

This single piece of data, provided with every set of Mustang

injectors from DeatschWerks, can potentially save tuners hours in

custom tuning work, and owners hundreds of dollars.

With Mustangs the data needed to tune includes:

Fully Balanced

- High-Slope: This number defines the linear range of the fuel injector

- which typically consists of pulsewidths greater than 2-3

- milliseconds. It is needed for proper tuning under high throttle

- conditions.

- Low-Slope: This number defines the non-linear range of the injector

- which typically consists of pulsewidths less than 2-3 milliseconds. It

- is needed for proper tuning of idle and light throttle conditions. This

- is the part throttle, lower power driving situations.

- Break Point: This number defines the transition point from non-linear

- (low pw) to linear (high pw).

- Battery offset: This table compensates for variations in battery

- voltage which can effect the opening time of the fuel injector.

- Having all of this data available means that even on high powered

- applications drivability is vastly improved because the injector tables

- are fine tuned from this information. This also saves even the most

- experienced tuners a lot of time, since they will not have to find a

- starting point based on their experience and then conduct

- drivability, and other tests to refine the injector portion of a custom

- tune.

matched set of injectors.

DW has developed a proprietary system for flow-balancing known as

Multi-Point Dynamic Flow Balancing (MPDFB). In the past, injectors were

typically tested using static balancing. This process ran the injectors

wide-open “static” for a set amount of time. Each injector sprayed liquid

into a graduated cylinder during that cycle, and the numbers from each

were then compared. Injectors were then typically grouped together in

sets that had similar “static” flow rates.

The trouble is that fuel injectors are not static fuel metering devices. “Fuel

injectors are very dynamic components, constantly opening and closing

multiple times per second,” syas Deatsch. This is why he says that DW

developed their (MPDFB) system. “This type of flow balancing quantifies

the fuel delivery of each injector across the full range of pulsewidths

injectors operate in the car. This includes a low, or start condition pulse

width, idle pulse width, mild acceleration pulse width, and high, or full

throttle level pulse widths.”

A DW technician prepares a set of injectors for flow balancing.

Left: Injector balancing is performed using graduated cylinders.

Injectors are then run over a variety of duty cycles to check their

flow rates. This set is not balanced due to the large discrepancy

between their flow numbers. Right: This set of injectors is considered

balanced because their flow is very closely matched, meaning they

will deliver consistent fuel delivery across all cylinders.

The MPDFB process could be compared to blueprinting an engine or looking

at the area under the curve on a dyno graph. All of the data is recorded

and compared, and each injector is scribed with an identifying number so it

can easily be referenced. By doing this injectors can be precisely matched

as a set, ensuring consistent performance at full throttle, and stock-like

starts, idle quality, and drivability in all other driving situations.

Quality And Service

EV1, EV14, GDI, and more. DeatschWerks can provide Mustang

owners with the right injector for their engine.

The last area to look at when selecting a set of injectors for any

performance application is the quality of the product and the customer

service. That guy selling “refurbished” injectors on eBay is likely not going

to give the time of day if or when there’s a problem with installation or

tuning. Having a company that is easily accessible and eager to help their

customers creates a kind of partnership through that level of service, and

is paramount to getting any project car set up properly.

According to Deatsch all of the factors we’ve discussed in this article are

critical in creating a good product, but customer service is also a key at

DW. Getting tech support to choose injectors before the sale, and then

helping with tuning, or trouble shooting after the fact is something

DeatschWerks prides themselves in, along with their extensive R&D process

and injector services.

Sources

Deatschwerks

Terry

Call

Send SMS

Add to Skype

You'll need Skype CreditFree via Skype

Last edited: