Hmm, some good questions here. Let me try to put some thoughts together about splitters on S197s... this is just my experience, and not meant to be some "splitter FAQ". I'm no expert in this field but I work with some other great engineers and fabricators here at Vorshlag and we've made a bunch of different splitters for Mustangs and other cars. Use this or ignore it, your choice.

Its no secret that adding downforce and aero drag reduction are important to lowering lap times on a road course, and to a much smaller degree it also helps lower times in autocross (which is what the OP asked about). Every car can benefit from downforce, when done correctly. There are some easy things on a splitter design -

the low hanging fruit - that make the most improvements.

Adding a rear wing is

relatively easy and the concepts are well understood, and this adds

rear downforce quite effectively on almost any body shape. That's a whole other subject, but my point is - if you have added a rear wing, you should look at adding a

front splitter to balance out the aero loading on the other end of the car.

Splitters reduce drag, limit airflow under the car, and if made correctly create a vacuum at the front - which creates negative pressure, and thus downforce on the front wheels. The gap between the splitter and the ground must be maintained, however, and often racers will apply "rub blocks" under the splitter to help space it up and maintain some airflow. With a ducted hood a splitter is even more effective, too.

Faux Splitters

First note:

ABS is not a good material for splitters. We ran the 2012 Boss 302 Laguna Seca splitter (made of 3/8" thick ABS plastic) in SCCA's STX and ESP classes on our red 2011 GT, for two reasons: 1) it was a far larger splitter than SCCA normally allowed in STX or ESP, but since it was an OEM piece we ran it. We felt initially that "it couldn't hurt". 2) Since many folks didn't know this was an OEM piece we could legally update/backdate to, the sight of this splitter got folks spun up, so it was good psychological warfare. Get them spun up over nothing.

In reality, as we later learned, this ABS splitter does almost nothing to produce usable downforce. It deflects markedly under load at higher track speeds. We had the factory splitter rip off this LS Boss above at TWS at 140 mph, after it deflected a lot. Caused about $1000 worth of damage to the front end, and took me an hour to zip-tie the car back together. This LS splitter is a decent enough flat bottomed "front under tray" but that's about it. Faux Splitter.

I've seen too many home-brew splitters, especially in SCCA autocross, made of "sign shop material". Things like Alumilite (see above) or other corrugated plastic/aluminum hybrid materials that are mostly air. My rule is if two fingers on one hand can permanently deflect and damage a splitter, it wasn't ever going to work on track or autocross. Pikes Peak last year had an Alumilite splitter come off and cause the car to crash. They fly off violently when they get serious downforce on these materials. And a minor cone hit can utterly destroy this stuff. "Just say no!" to corrugated sign shop material.

This splitter was good enough for the SMod win at the 2009 Solo Nats on one of our tester's cars

Materials

There are really only 3 materials, we feel, that are suited for making splitters:

1. Carbon fiber (stiff and light, expensive to make, shatters easily),

2. Aluminum (easy and somewhat inexpensive to make, durable/repairable, stiff but has some mass)

3. Plywood (cheap to make, not as stiff, durable and "wearable", but the heaviest option).

For those of us not in professional racing or that don't have the skills and tools, carbon fiber is not a good answer. They are the lightest option, but one good hit and they are toast. Wood is cheapest and I encourage folks to try this out for their first "splitter projects". They still show up in pro racing paddocks, so don't be ashamed. We used 1/2" plywood on a number of splitters, including our $2011 GRM challenge winning BMW E30 LSx (above) and the Pikes Peak Subaru STi (below).

The Subaru was driven on a course (PPIHC) that had a lot of "curb cuts", radical camber changes in the surface, and driven at the apex of many curves it takes a

massive beating - from hits and abrasion on asphalt. Its still going 3 years of Pikes Peak later. We were able to make spares for about $25 in materials, so plywood is hard to beat when you

beat up the splitter a lot. And you could still stand on it, but we did have some extra aluminum tubing structure hidden above the splitter (see below).

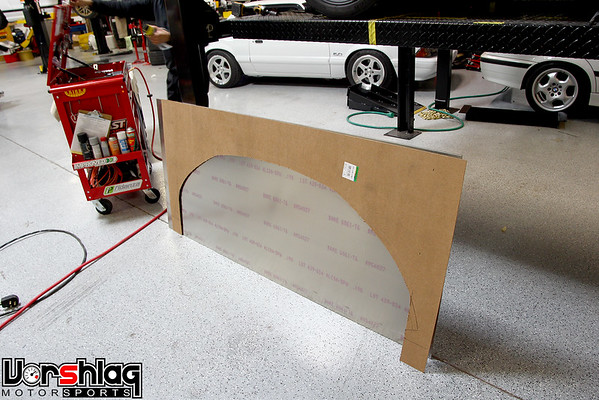

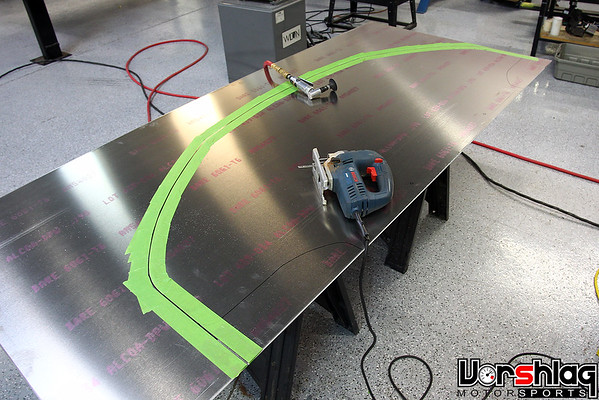

Last, and our go-to material, is aluminum. We use two thicknesses - 1/8" (.125") and 3/16" (.1875"), using 6061-T6 plate material. This can cost you $200-300 for a 4x8' sheet and we usually use a cheap 1/8" pressboard material to make a template from, perfect hole placements, then transfer this to the aluminum plate.

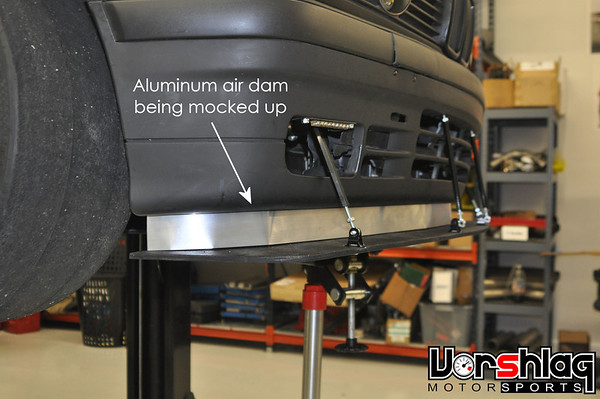

You need a flat edge along the front of the car to mount a splitter to, It is remarkable how UN-flat most cars are at the front. One of the projects we're working on is a BMW E46 and none of the factory front bumpers (of many) are flat at the front.

So you often have to make an "air dam" section first, which can give you that flat leading edge to mount to.

This air dam section needs to seal pretty well to the splitter plate itself, or you are going to add a lot of drag and/or lose downforce.

Once you have the leading edge/air dam, then you can make your template. A big piece of cardboard can work but we like to use a cheap/thin piece of pressboard - it makes for a better template you can re-use.

You are on your own for the rear mounts - I can't give away ALL our secrets.

The front struts are pretty self-explanatory, and again - I'm going to let you find these on your own, too. We have used a number of suppliers and found there is a big difference in quality.

Know The Rules

There are almost always class rules that will limit the splitter length forward, length aft, width, and sometimes height from the ground. These things all effect efficiency and downforce, which is why there are usually rules to restrict each variable. Additional dive planes or canards can add more downforce but might be restricted or outlawed.

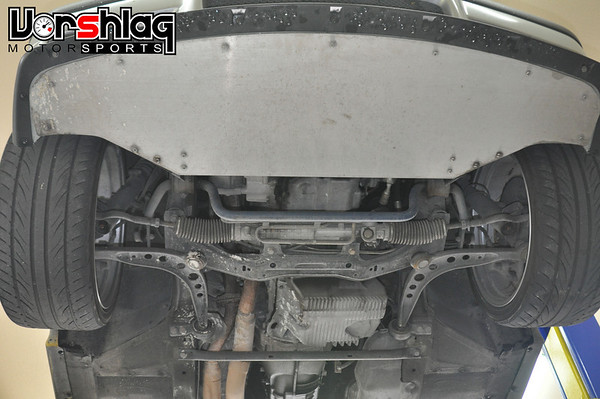

Go as far back as the rules allow - usually the limit is the "front axle centerline". Even without a protruding "splitter" a flat bottom undertray is still a good idea, and tends to reduce undercar drag (see below).

Most rules prohibit a "flat bottomed car" because it works even better, but if the factory design was flat bottomed, you can keep that (Ferrari, Corvettes, etc).

A properly designed, flat bottomed splitter on a typical sedan should make ~100-300 pounds of front downforce, so it

should be able to withstand the weight of at least one full sized adult standing on the end. That's a test we use on

all splitters we make. The factory Boss302 LS splitter will rip right through the (2) front strut mounts if you try this. My advice: only do this on wood or aluminum splitters you are confident in.

What Matters Most

Splitter length is important, and the longer it is, it seems to make more downforce it tends to make. The old rule of thumb was "anything beyond 6 inches of forward extension" past the bumper is wasted, but that's not what we've seen in testing - we had a 10.25" extension that made too much front downforce for the wing we had at the time. Cutting 4" off the front of that thing reduced front downforce and made the balance more stable in high speed corners. This isn't extensive aero testing, of course, and if you can make the splitter go back past the front axle centerline it could be more effective than the long front overhang.

Also, make the splitter plane as wide as you care to - but if the tracks you frequent have substantial edge curbing, keep that in mind. Width is often limited in rules.

And of course get the splitter as close to the ground as you can. You need to factor in brake dive (shown above), of course, but with increasing aero loading (front and rear) the spring rates tend to go higher and higher... otherwise the car is going to compress the springs to the bump stops. NOTE: a very low splitter height and/or a long front extension on the splitter makes loading a car onto a trailer "fun" (read: time to buy long ramps) and makes street driving "difficult".

Hope this helped. I'll have Jason re-read this and make corrections based on his edits.

Cheers,