Been sitting on this one a while, ~ a year. It started with a late night oil change, and under the garage lights I saw glitter in the oil -- a concerning amount of it. But the engine was running fine. No noises, stumbles, etc. Just as smooth as ever. But I was worried about it after one hard pull onto the highway getting off of midnight shift one morning before the engine was fully warmed up. So I sent in the oil for analysis, saying I was worried that it might be from my aftermarket cams and they said

I decided to keep it safe and change the oil every 500 mi and drive it like a Prius....alright alright....drive it like a normal car and keep the RPMs under 3500 and never go more than 1/2 throttle. Things were going pretty well with that plan. The car continued to sound normal, the glitter in the oil was basically gone, just what you could attribute to remnants from the original anomaly.

Still had been talking to my local shop about a rebuild just in case and they'd been lagging for months on a quote (don't blame them, they've got a ton business and they were short handed for a bit).

So last month I had this brilliant idea -- I said screw it, the car's either fine or it's not. I took it on a 600 mi road trip, mostly highway and still driving it easy. I let the oil go up to 1500 miles to get a longer term reading and sent it in for analysis again (should get that back any day now). Well, the verdict came in. And fine its not. The engine developed a tick a couple weeks ago, so I brought it into my trusted shop to see if they could find it. It didn't take them long:

Had a chat with them about it, Here's what they said:

"If you look closely at the cam, second and fourth lobe from the right, you'll note the grey pattern starting to develop on the second. That's the hardened surface starting to wear off On the fourth it has changed to a rough texture indicating high wear through the hardened surface. Several others are starting to show the grey pattern too. "

We talked about a few different options, and he's working on quotes to handle each of them. But here they are in order of $$$

1. Just replace the cams and followers. It'll get rid of the tick and I can pray that the metal in the oil didn't cause premature wear on anything else. The oil reports so far at least support the idea the bearings are still OK.

2. Replace the engine with a rebuilt stock 3V.

There's a company (forgetting the name right now) that will sell a turn-key engine with a 100k mile warranty, but then I'm back down to stock power levels. And it's been a loooooong time for me since 255 rhwp was good enough. It may end up being 2/3 the cost of the next option.

3. Rebuild the motor. For the labor cost around here, we'd be looking at forged internals in prep for a supercharger down the line. Some builds they've done will support 800 HP, though I don't think I'd ever wanna go that nuts.

4. We didn't talk about this one-- Coyote swap. Certainly wouldn't be cheap. Even just the engine is $10k and that's before mounts, harnesses, control packs, exhaust, air conditioning kits, etc

It's a lot to consider right now, although #2 I think is pretty much out. For what they thought it was going to cost I think it'd be pretty dumb to spend that kind of cash and lose that much power.

Option #1 is the cheapest but still a risk. Option #3 would start getting me closer to what I originally planned for the car 17 years ago -- supercharged.

There's also an Option #5, which would be to fix the tick by reverting the cams & intake to stock (kept the parts), and just sell the car. I don't like that option for a bunch of reasons. Sentimental value obviously #1. Also have a ton of work into the car, lots of mods and I really love the way it drives. It'd be pretty hard to find another car that ticks all the boxes for me the way this one does... especially for a reasonable price. I've been looking around a little bit and used car prices are still way up there (saw a '12 BOSS 302 for $40k! 11 years old for $40k! GT350 -- ~$55k for a 2017)

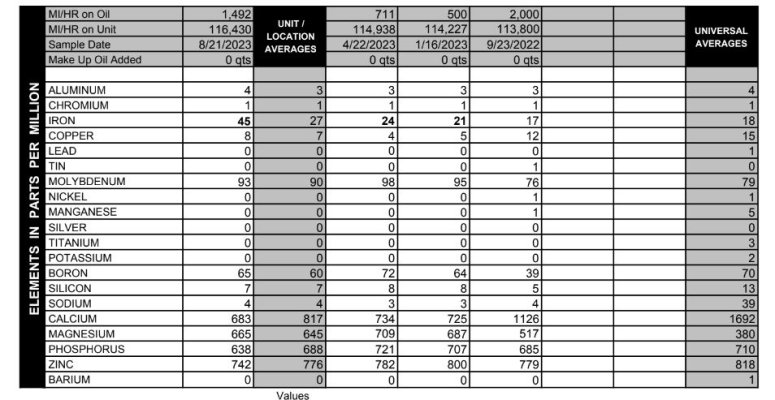

Metal large enough to see is too big for our spectrometer to read, but on the microscopic level, we didn't find any big red flags when it comes to engine wear. Universal averages for this kind of Ford are based on 4,700 miles. Iron (from steel parts, including the cam) probably could've been a little lower for the shorter run, but we would hesitate to call a problem based on this level. If visible metal persists, iron heads upward in analysis, and/or you start hearing unusual noises/having operational issues, our tune might change. A trace (TR) of fuel is harmless.

I decided to keep it safe and change the oil every 500 mi and drive it like a Prius....alright alright....drive it like a normal car and keep the RPMs under 3500 and never go more than 1/2 throttle. Things were going pretty well with that plan. The car continued to sound normal, the glitter in the oil was basically gone, just what you could attribute to remnants from the original anomaly.

Still had been talking to my local shop about a rebuild just in case and they'd been lagging for months on a quote (don't blame them, they've got a ton business and they were short handed for a bit).

So last month I had this brilliant idea -- I said screw it, the car's either fine or it's not. I took it on a 600 mi road trip, mostly highway and still driving it easy. I let the oil go up to 1500 miles to get a longer term reading and sent it in for analysis again (should get that back any day now). Well, the verdict came in. And fine its not. The engine developed a tick a couple weeks ago, so I brought it into my trusted shop to see if they could find it. It didn't take them long:

Had a chat with them about it, Here's what they said:

"If you look closely at the cam, second and fourth lobe from the right, you'll note the grey pattern starting to develop on the second. That's the hardened surface starting to wear off On the fourth it has changed to a rough texture indicating high wear through the hardened surface. Several others are starting to show the grey pattern too. "

We talked about a few different options, and he's working on quotes to handle each of them. But here they are in order of $$$

1. Just replace the cams and followers. It'll get rid of the tick and I can pray that the metal in the oil didn't cause premature wear on anything else. The oil reports so far at least support the idea the bearings are still OK.

2. Replace the engine with a rebuilt stock 3V.

There's a company (forgetting the name right now) that will sell a turn-key engine with a 100k mile warranty, but then I'm back down to stock power levels. And it's been a loooooong time for me since 255 rhwp was good enough. It may end up being 2/3 the cost of the next option.

3. Rebuild the motor. For the labor cost around here, we'd be looking at forged internals in prep for a supercharger down the line. Some builds they've done will support 800 HP, though I don't think I'd ever wanna go that nuts.

4. We didn't talk about this one-- Coyote swap. Certainly wouldn't be cheap. Even just the engine is $10k and that's before mounts, harnesses, control packs, exhaust, air conditioning kits, etc

It's a lot to consider right now, although #2 I think is pretty much out. For what they thought it was going to cost I think it'd be pretty dumb to spend that kind of cash and lose that much power.

Option #1 is the cheapest but still a risk. Option #3 would start getting me closer to what I originally planned for the car 17 years ago -- supercharged.

There's also an Option #5, which would be to fix the tick by reverting the cams & intake to stock (kept the parts), and just sell the car. I don't like that option for a bunch of reasons. Sentimental value obviously #1. Also have a ton of work into the car, lots of mods and I really love the way it drives. It'd be pretty hard to find another car that ticks all the boxes for me the way this one does... especially for a reasonable price. I've been looking around a little bit and used car prices are still way up there (saw a '12 BOSS 302 for $40k! 11 years old for $40k! GT350 -- ~$55k for a 2017)

), and the way I was looking at it, if I'm eventually going to do a forged build, that $3k could go a not inconsequential sum towards it.

), and the way I was looking at it, if I'm eventually going to do a forged build, that $3k could go a not inconsequential sum towards it.