ebrow21

forum member

A couple of suggestions.

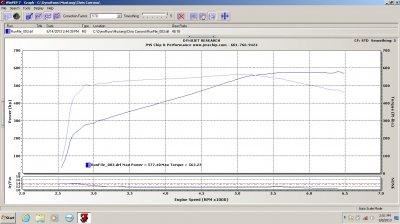

Cody (Stang-Hi) posts STD numbers, and the car was probably cool/cold when that number was run. It was over a 20hp difference STD/SAE when my old nitrous 3v car was tuned by Cody, and I made nowhere near 604hp. I would also imagine that was a hero run. If I remember right, JMS uses SAE numbers.

I spoke to (and raced) the previous owner when the car was out at a local meet. I ended up talking to him about the car a good bit. If I remember right, the Whipple was put on when the car was purchased new. Meaning, it has almost 100k miles on it, and its a Gen I. Also, the built motor had around 30k miles. The guy used the car daily and on long trips without a hiccup, but he didn't do any updates to the car either.

Looking at the heat exhanger system was my suggestion then to him, and I agree with everyone above that it will help your car immensely. That pump has been working for 100k miles, I wouldn't imagine it can be as efficient as new. The belt, tensioner, etc. all have at least 30k miles as well, unless they're something you've replaced since purchase.

Just based on what a low boost Whipple does on my Coyote, I would imagine you see 200+ degree IATS if you romp down hard on that thing in the heat.

Cody (Stang-Hi) posts STD numbers, and the car was probably cool/cold when that number was run. It was over a 20hp difference STD/SAE when my old nitrous 3v car was tuned by Cody, and I made nowhere near 604hp. I would also imagine that was a hero run. If I remember right, JMS uses SAE numbers.

I spoke to (and raced) the previous owner when the car was out at a local meet. I ended up talking to him about the car a good bit. If I remember right, the Whipple was put on when the car was purchased new. Meaning, it has almost 100k miles on it, and its a Gen I. Also, the built motor had around 30k miles. The guy used the car daily and on long trips without a hiccup, but he didn't do any updates to the car either.

Looking at the heat exhanger system was my suggestion then to him, and I agree with everyone above that it will help your car immensely. That pump has been working for 100k miles, I wouldn't imagine it can be as efficient as new. The belt, tensioner, etc. all have at least 30k miles as well, unless they're something you've replaced since purchase.

Just based on what a low boost Whipple does on my Coyote, I would imagine you see 200+ degree IATS if you romp down hard on that thing in the heat.