3VVV

Junior Member

Hi everyone!

My log shows strange spikes in the fuel rail pressure and I can't make sense of it - I hope you guys can?

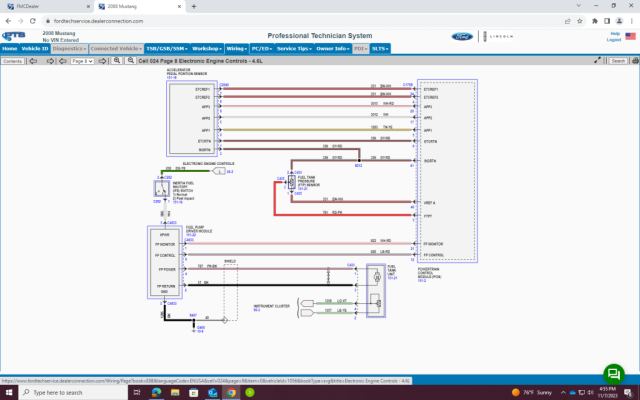

My 2008 GT Automatic had issues with loud pinging/detonation on hot days.

I flashed the stock software back on and ran some logs to see what was going on (engine is otherwise stock).

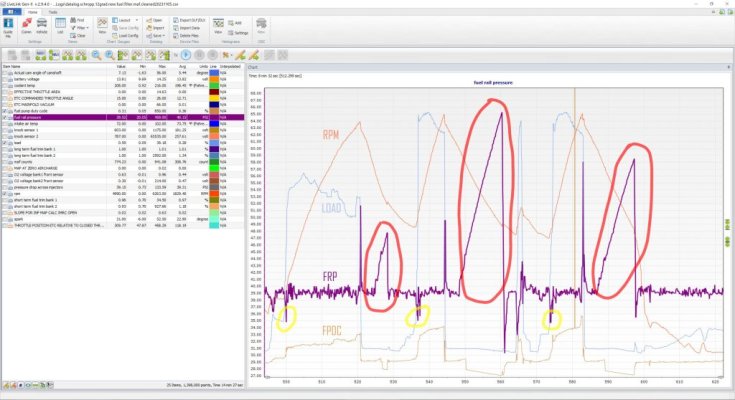

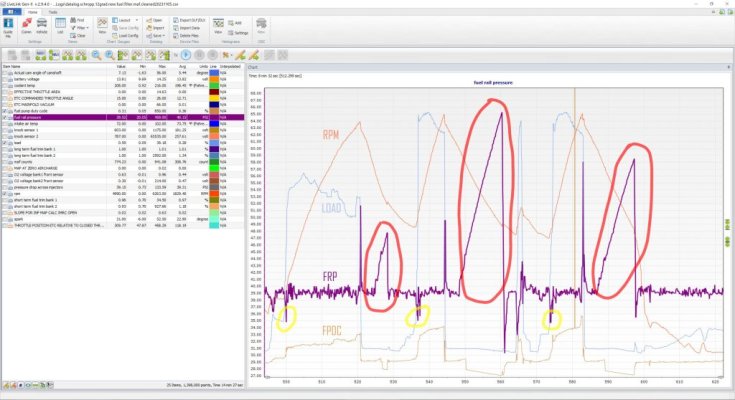

LTFTs were high under load and fuel pump duty cycle went up to .48 (96%), so obviously a fuel delivery problem.

I changed the fuel filter, cleaned the MAF and reset the KAM. Now LTFTs look fine (0-3%) but fuel pump booty cycle is still high at .44 (88%) WOT and .26 (52%) idle.

I ordered a new sock filter/restrainer for the pump - but there is something else going on that I don't understand:

My fuel rail pressure increases dramatically for up to 10 seconds whenever I let off from high RPM (marked red). WHY?

Another issue is that whenever load is applied, the fuel rail pressure drops for a second (marked yellow). I guess that could be fuel restriction and will hopefully disappear once the sock filter is changed?

Anyone having an explanation for the spikes?

Thanks and best regards!

My log shows strange spikes in the fuel rail pressure and I can't make sense of it - I hope you guys can?

My 2008 GT Automatic had issues with loud pinging/detonation on hot days.

I flashed the stock software back on and ran some logs to see what was going on (engine is otherwise stock).

LTFTs were high under load and fuel pump duty cycle went up to .48 (96%), so obviously a fuel delivery problem.

I changed the fuel filter, cleaned the MAF and reset the KAM. Now LTFTs look fine (0-3%) but fuel pump booty cycle is still high at .44 (88%) WOT and .26 (52%) idle.

I ordered a new sock filter/restrainer for the pump - but there is something else going on that I don't understand:

My fuel rail pressure increases dramatically for up to 10 seconds whenever I let off from high RPM (marked red). WHY?

Another issue is that whenever load is applied, the fuel rail pressure drops for a second (marked yellow). I guess that could be fuel restriction and will hopefully disappear once the sock filter is changed?

Anyone having an explanation for the spikes?

Thanks and best regards!

Last edited: