Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

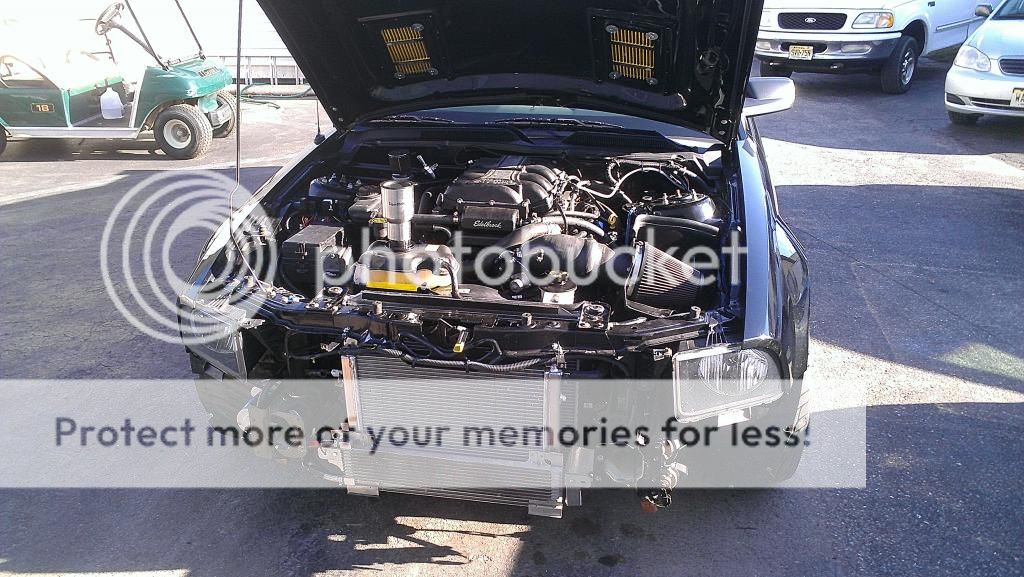

I installed mine in the stock ROUSH location.

My setup runs cool...its never been hot. Even after a 20 min track session or a 2 hour road trip, you can touch the tank without burning yourself. Its warm to hot, but I suspect most of the heat is transferred from the engine bay heat into the reservoir as its an aluminum tank.

I want to replace my Meziere pump not due to coolant issues, but more so I want a cleaner and quieter setup.

Plus I have found slight moistness around the bottom of the pump, but hoses and hose fittings are dry. I am thinking its coming from the lower half of the pump.

Your first problem is that it's hard mounted. If you rubber mount it with a couple of those rubber isolator things it will be near silent. Any hard mounted pump will make a lot of noise.

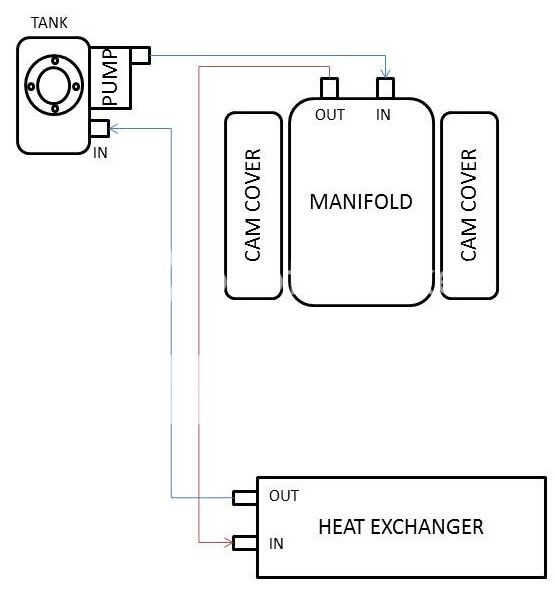

Your second problem is where the pump is in the system. You want it after the HE and before the IC. It looks to me like you have it after the burp bottle and before the HE.

If the pump is weeping fix it.