tmcolegr

It's All About the Build

Moderators if you don't feel this thread qualifies as tech please move as you see fit.

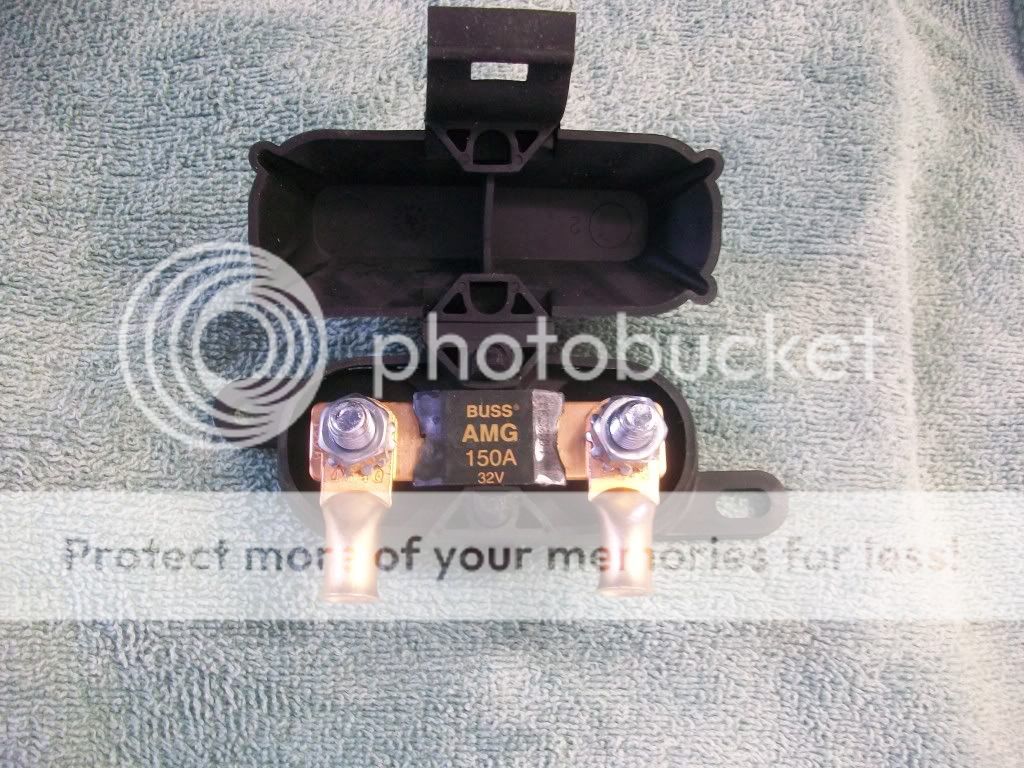

I am in the process of making up a parts list for relocating the battery to the trunk. This relocation is NOT intended to meet NHRA requirements - just freeing up space for a battery box mounted I/C reservoir. After reading through all the battery relocation threads, I didn't see many that mentioned installing a high amp fuse in the (+) battery cable at the battery. So after researching several manufacturers I came across these:

http://www.streetwires.com/products/default.aspx?grp=66

Is anyone else using these or something similar? I will need (2) as I am using dedicated positive (+) battery cables - (1) for the alternator and (1) for the Starter/BEC. I'm thinking 150 amp fuse for the alternator cable (I am still using the stock 130 amp alternator - therefore only a 150 amp fuse) and 200 amp fuse for the Starter/BEC cable.

Additional information on my battery relocation. I'm planning on using:

If any of you that have previously relocated your battery to the trunk see a flaw in this logic/plan please feel free to chime in.

I am in the process of making up a parts list for relocating the battery to the trunk. This relocation is NOT intended to meet NHRA requirements - just freeing up space for a battery box mounted I/C reservoir. After reading through all the battery relocation threads, I didn't see many that mentioned installing a high amp fuse in the (+) battery cable at the battery. So after researching several manufacturers I came across these:

http://www.streetwires.com/products/default.aspx?grp=66

Is anyone else using these or something similar? I will need (2) as I am using dedicated positive (+) battery cables - (1) for the alternator and (1) for the Starter/BEC. I'm thinking 150 amp fuse for the alternator cable (I am still using the stock 130 amp alternator - therefore only a 150 amp fuse) and 200 amp fuse for the Starter/BEC cable.

Additional information on my battery relocation. I'm planning on using:

- Odyssey PC1200MJT battery

- Odyssey HDB 1200 battery hold down mounted in the center of the trunk

- Dedicated (+) full length welding cable for the alternator (4 gauge) routed through the interior passenger's compartment

- Dedicated (+) full length welding cable for the starter/BEC (1 gauge) routed through the interior passenger's compartment

- Dedicated (-) full length welding cable for engine/chassis ground (1 gauge) routed through the interior passenger's compartment. Note: the ground cable should only need to be the same size as the (-) battery cable for the starter/BEC cable as the alternator will never be producing current at the same time the vehicle is cranking.

- Battery disconnect switch mounted in the trunk for the (-) battery cable only as a convenient method to disconnect the battery to perform maintenance or repairs to the electrical system.

If any of you that have previously relocated your battery to the trunk see a flaw in this logic/plan please feel free to chime in.

Last edited: