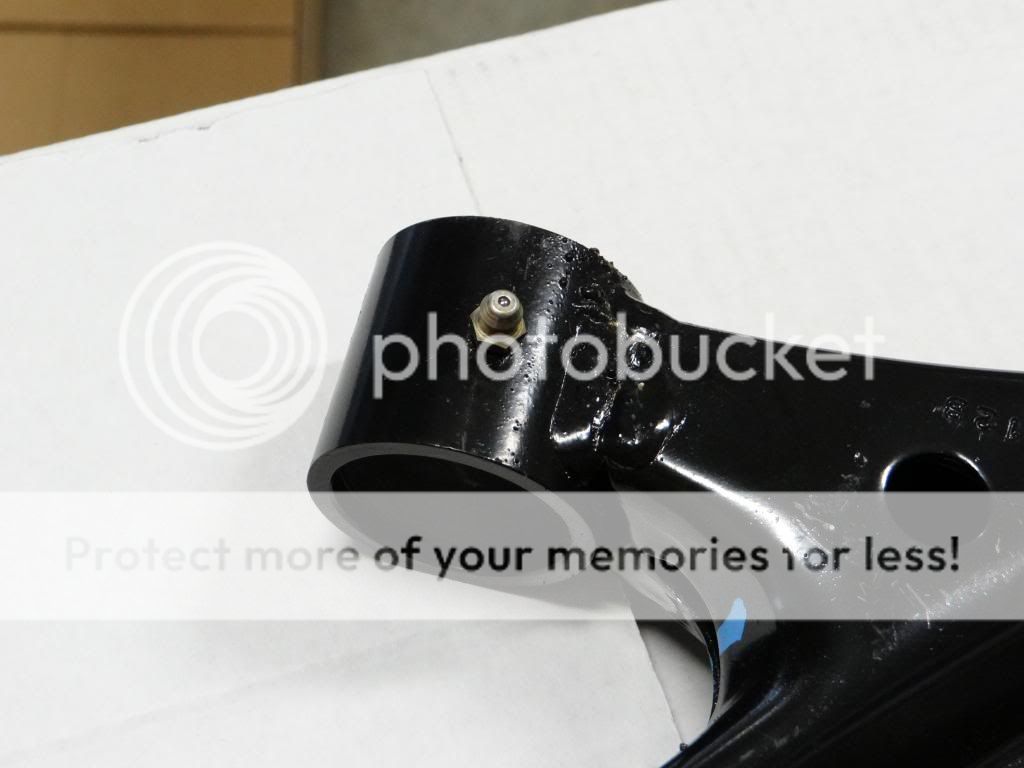

Alright, so here are the Boss 302S A arms I got in the mail. Of course they're nice an pretty unlike my old rusty ones that are the originals. I'm sure these will look the same before long. But I must say, I do like the new arm design and it seems like it would be stouter.

In any case, the ball joint at least is BEEFY.

And it is a screw in type which will make it a LOT easier to replace when it goes bad.

The grease fitting for the front bushing was a pleasant surprise.

The only problem now is this whole.

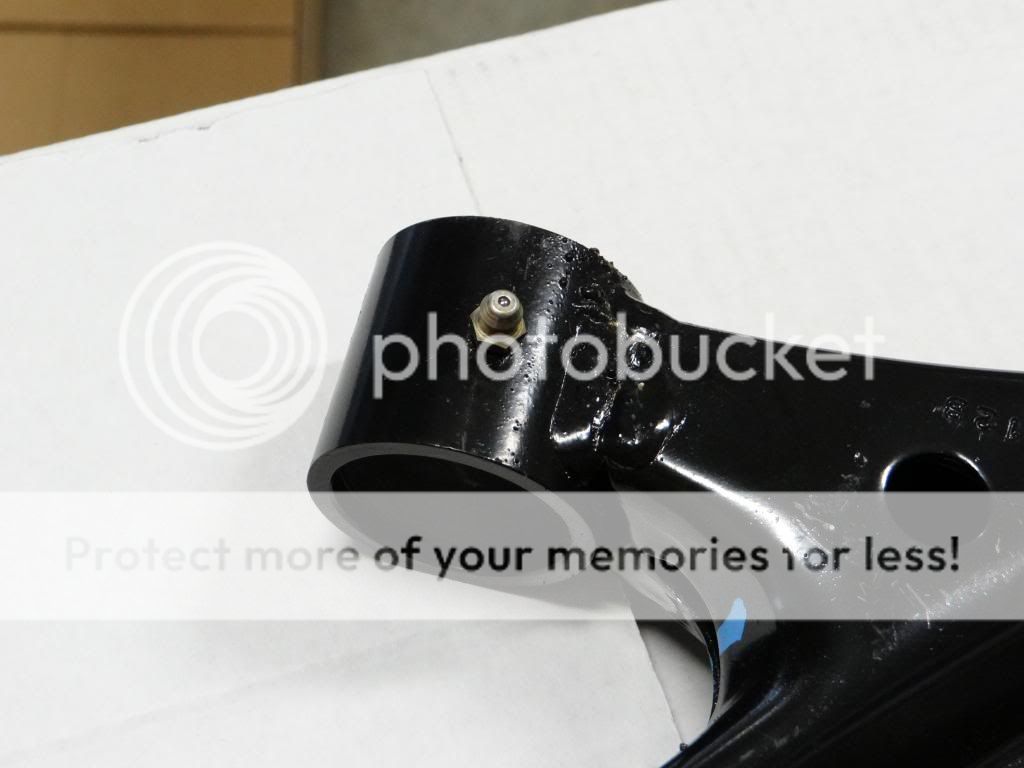

In any case, the ball joint at least is BEEFY.

And it is a screw in type which will make it a LOT easier to replace when it goes bad.

The grease fitting for the front bushing was a pleasant surprise.

The only problem now is this whole.