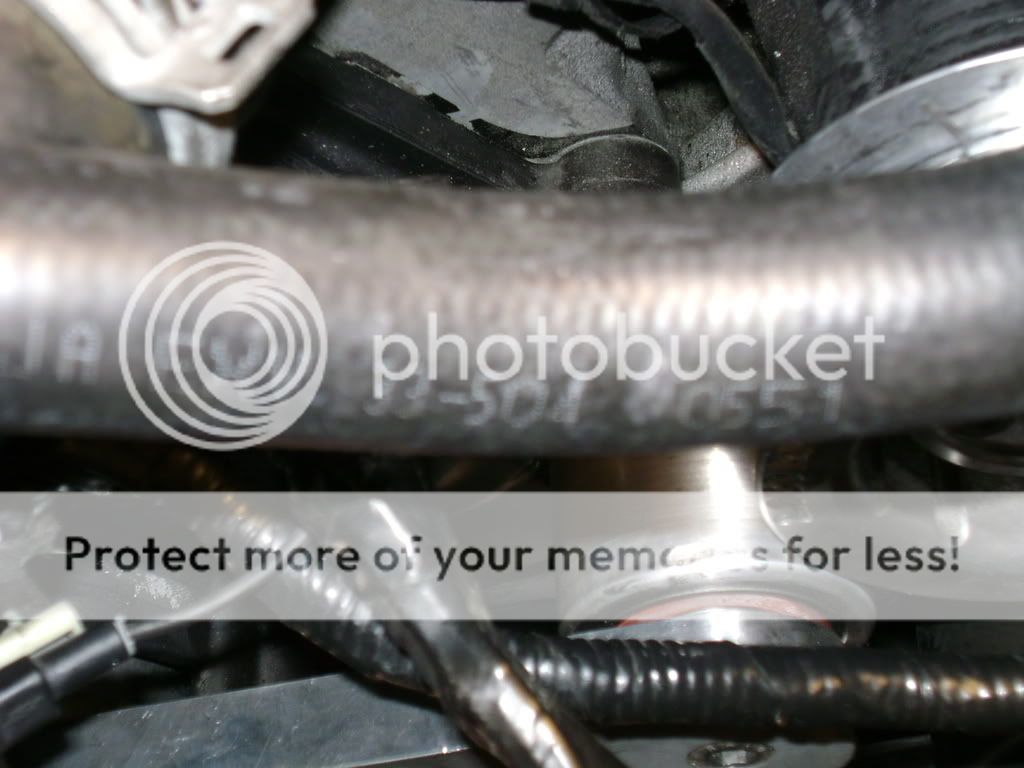

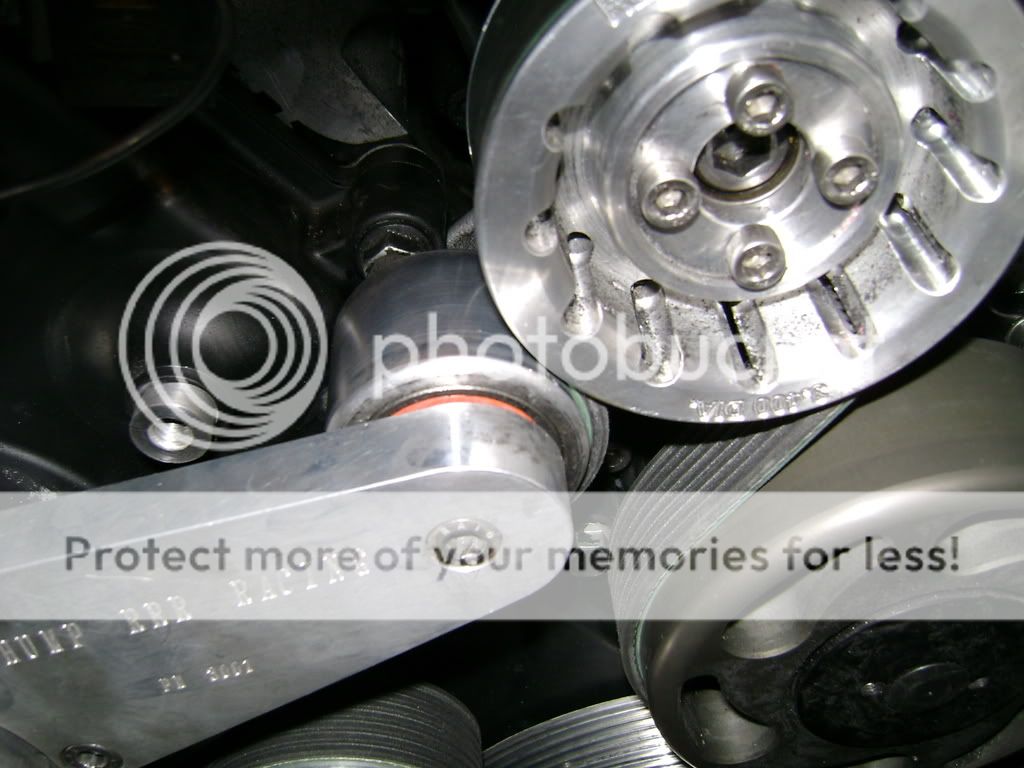

So I finally got the belt size I need to run my 2.95" S/C pulley. It is exactly 110.25" long Goodyear gator back. So I took my car to my buddies house and we but the new belt on and the smaller S/C pulley. We got everything on and buttoned up. I crank the car the engine goes and then I here a very loud snap and hear metal falling. I immediately shut down the car. Under the car we see oil dripping down and find the lower idler pulley that goes behind the alternator on the Saleen S/C setup. The oil filter was busted up from where the idler pulley collided with it. The idler pulley and bolt snapped out of the timing cover.

Has anyone else broke off an idler pulley like this? How had is it going to be to swap out the idler pulley. I know I'm going to have to take off all the accessory pulleys and the crank pulley. Other then that is should be pretty much a straight swap correct?

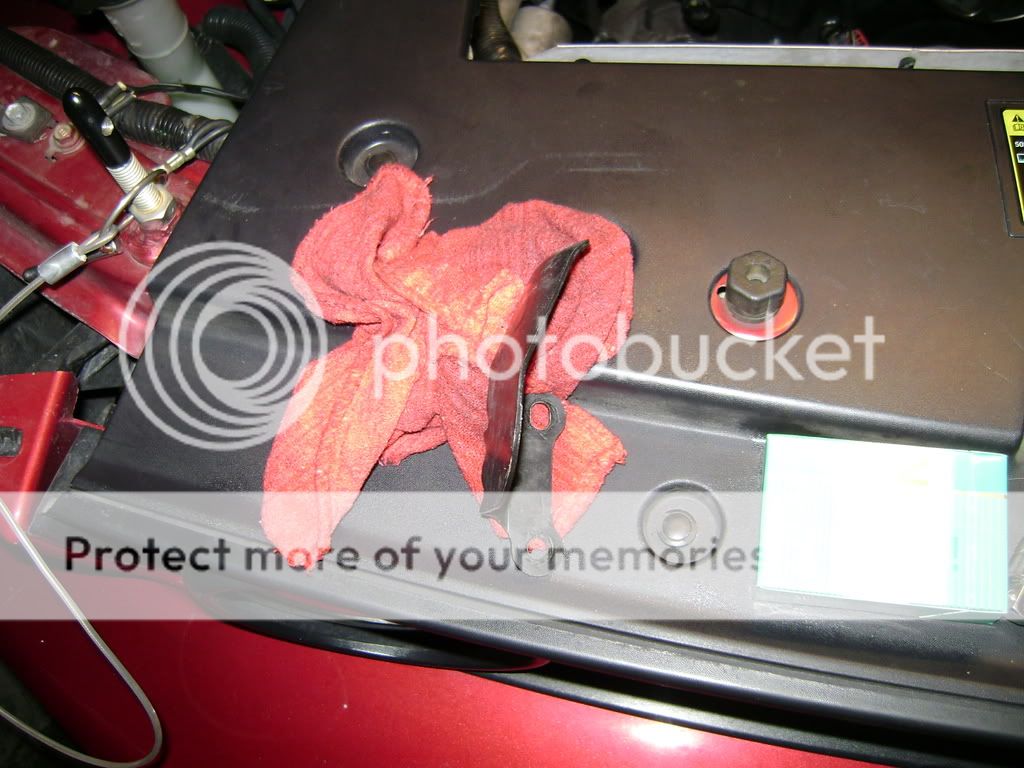

I didn't have a camera with me tonight. We plan on hopefully tearing down the front end of the car tomorrow and get a good look at everything. I am hoping that nothing else is damaged. My friend thinks that the mount for the oil filter may have been damaged too. Is that part of the engine block on a teksid block or does it bolt in?

Has anyone else broke off an idler pulley like this? How had is it going to be to swap out the idler pulley. I know I'm going to have to take off all the accessory pulleys and the crank pulley. Other then that is should be pretty much a straight swap correct?

I didn't have a camera with me tonight. We plan on hopefully tearing down the front end of the car tomorrow and get a good look at everything. I am hoping that nothing else is damaged. My friend thinks that the mount for the oil filter may have been damaged too. Is that part of the engine block on a teksid block or does it bolt in?

Could be worse...

Could be worse...