GlassTop09

Senior Member

FYI.......................

I was killing some time today so I pulled up a 1st Gen Copperhead PCM tune file (11-14 MY Coyote engines) in HPTuners Editor software then set up a '05 GT SO PCM tune file in Compare & looked at the Knock Sensor section & found that Ford used the exact same KS mic to cyl assignment mapping for both the 05-10 4.6L 3V & 11-14 5.0L Coyote engines that I found an error in this mapping that was causing some false cyl knock\aggravated cyl knock levels in certain cyls according to engine firing order sequencing during self-tuning on my '09 GT which was using this exact same KS mic to cylinder assignment pattern that I resolved on my '09 GT by reassigning #2 cyl from #0KS mic to #1KS mic & #6 cyl from #1KS mic to #0KS mic as these 2 cyls were the ones assigned out of firing order "phasing" for the KS mics causing the following cyls from the 1st cyl assigned in firing order to receive elevated KS mic voltage signal output generation due to successive cyls firing in the 90* firing sequence using the same KS mic as the 1st cyl, instead of using the opposite KS mic from the leading cyl.

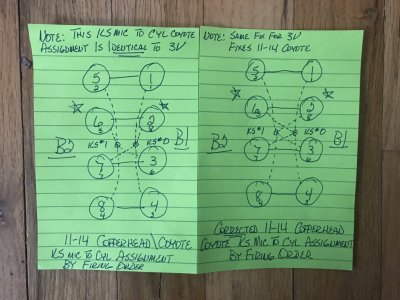

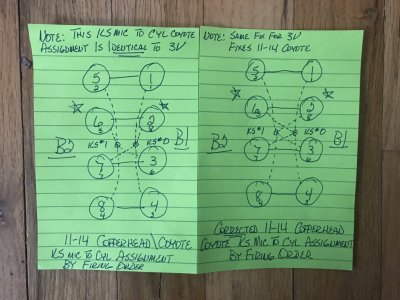

I drew these pictures to represent this KS mic to cyl assignment pattern as found in the Copperhead tune file I was looking at then w\ the corrected KS mic to cyl assignment pattern that will correct the base KS mic voltage output signal "phasing" to each leading\following cyl according to engine firing order sequence when engine is running when using all Ford tuned OEM per cyl knock sensitivity threshold map settings by reassigning the exact same 2 cyls in the exact same manner as the 2 engines are using the exact same engine KS mic to cyl assignment map settings:

The 11-14 Coyote's firing order sequence is denoted by the small number located at bottom of each cylinder. Just follow them in numerical order to follow actual engine firing order sequence to see what I'm explaining here.

Something to consider for all my 1st Gen Coyote brethren if your engine is suffering from crazy cyl knock issues\patterns. Don't take my word on this........test this out for yourselves.

I believe this KS assignment error (that it appears that Ford never identified\caught since 05.........) has a part to play as to why Ford, starting w\ the '15 & up MY's, went to a 4 KS mic arrangement (2 KS mics per bank of cyls) on all Coyote\Coyote variant engines.

07-10 Ford Mod Motor GT500 engines using the 5.4L SC V8 has this exact same KS mic to cyl assignment error in its tune files as well................

I was killing some time today so I pulled up a 1st Gen Copperhead PCM tune file (11-14 MY Coyote engines) in HPTuners Editor software then set up a '05 GT SO PCM tune file in Compare & looked at the Knock Sensor section & found that Ford used the exact same KS mic to cyl assignment mapping for both the 05-10 4.6L 3V & 11-14 5.0L Coyote engines that I found an error in this mapping that was causing some false cyl knock\aggravated cyl knock levels in certain cyls according to engine firing order sequencing during self-tuning on my '09 GT which was using this exact same KS mic to cylinder assignment pattern that I resolved on my '09 GT by reassigning #2 cyl from #0KS mic to #1KS mic & #6 cyl from #1KS mic to #0KS mic as these 2 cyls were the ones assigned out of firing order "phasing" for the KS mics causing the following cyls from the 1st cyl assigned in firing order to receive elevated KS mic voltage signal output generation due to successive cyls firing in the 90* firing sequence using the same KS mic as the 1st cyl, instead of using the opposite KS mic from the leading cyl.

I drew these pictures to represent this KS mic to cyl assignment pattern as found in the Copperhead tune file I was looking at then w\ the corrected KS mic to cyl assignment pattern that will correct the base KS mic voltage output signal "phasing" to each leading\following cyl according to engine firing order sequence when engine is running when using all Ford tuned OEM per cyl knock sensitivity threshold map settings by reassigning the exact same 2 cyls in the exact same manner as the 2 engines are using the exact same engine KS mic to cyl assignment map settings:

The 11-14 Coyote's firing order sequence is denoted by the small number located at bottom of each cylinder. Just follow them in numerical order to follow actual engine firing order sequence to see what I'm explaining here.

Something to consider for all my 1st Gen Coyote brethren if your engine is suffering from crazy cyl knock issues\patterns. Don't take my word on this........test this out for yourselves.

I believe this KS assignment error (that it appears that Ford never identified\caught since 05.........) has a part to play as to why Ford, starting w\ the '15 & up MY's, went to a 4 KS mic arrangement (2 KS mics per bank of cyls) on all Coyote\Coyote variant engines.

07-10 Ford Mod Motor GT500 engines using the 5.4L SC V8 has this exact same KS mic to cyl assignment error in its tune files as well................