Whatever happened to those AST units you used to sell?

To answer that is so complicated.... :/ We were the AST distributor for 4 years ('06-09), and we did all of the trade shows and their warranty work for all AST sets sold in North America, which was both costly and painful. AST can and has made a lot of great products, but the North American distributorship has changed hands twice since us, and there have been major personnel changes back at the Holland factory, not much new product development, the Moton acquisition, price increases - just to name a few of the challenges.

That's only a sliver of the issues, but there's so much going on there I don't want to get into it further. We are technically still an AST and Moton dealer, and to this day we've probably still sold more ASTs than any other dealer on the planet, but due to these issues and excessive lead times we disabled all of the AST and Moton entries on our website in 2013-14. I'm hoping there's a turn-around soon, but its been tough to be an AST dealer for the past few years. Again, they had some of the best and most innovative products at certain times, and I would like to be able to sell these again some day. Mostly it comes down to "unknown lead times", that can be very long.

A question on those since we are off on this related OT diversion. What is the rebuild requirements/interval on these guys? Would they be remotely appropriate for a DD/sometime HPDE & autocross car? ... if I have to take the suspension apart to rebuild annually, the advantages fade significantly.

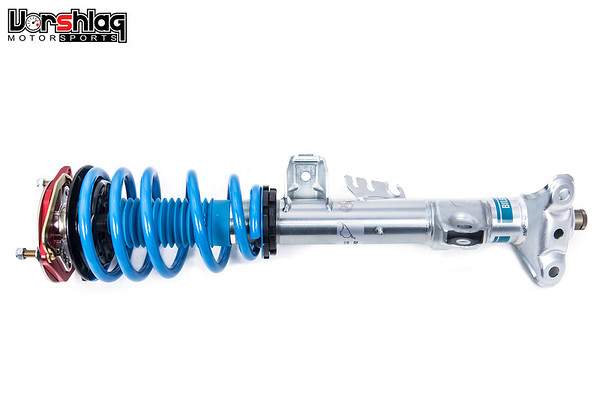

The more complicated a shock gets (remote reservoirs are a big factor, at left) the shorter the rebuild interval gets

Monotube adjustable shock rebuild intervals aren't a fixed quantity... its depends on so many variables. Usually you have to rebuild a monotube after:

1. It loses Nitrogen pressure, after which is will leak hydraulic fluid.

2. An adjuster malfunctions - like if it sticks, or spins more than the allotted number of "clicks" or rotations.

3. Any time there's a hydraulic leak at a seal, fitting or hose.

4. Something is bent or broken, from crash damage - obviously.

I've seen customers go 5-6 years before needing a look and others that need rebuilds every 2 seasons. Pro race teams and rally cars are much harder on their dampers and tend to rebuild them much more often, usually from crash damage.

If a monotube shock has hoses and remote canisters, that adds complexity and places for a leak. Lots of times these leaks have to do how the remotes are mounted, like if a hose has a swivel or is kinked when it is mounted. Or when they are near extreme sources of heat. Or if they are clamped in the wrong place, which can make a piston stick in the bore.

Torn or worn seals eventually cause leaks. Dirty/old fluid doesn't work as effectively

Shock fluid is a sciences all into itself, and the fluid wears and gets dirty - just like any other oil or fluid on a street or race car. "Low drag" seals in race shocks can and do allow more dirty to get into the fluid, but on a pro team the fluid is changed regularly, and the shocks are serviced often. The typical MCS TT1/TT2 doesn't use low drag seals, so they don't get as nasty, but tighter seals make for a tiny bit of stiction (like almost all dampers have). The shims in the "tree stack" of a monotube damper are a wear item as well, as they have to flex every time they are pushed. Eventually they can crack - but it takes a LOT of force or a LOT of cycles to do this, and they are usually just inspected, cleaned, and re-used (potentially for many many years). I am probably forgetting something, too... this isn't a perfect list.

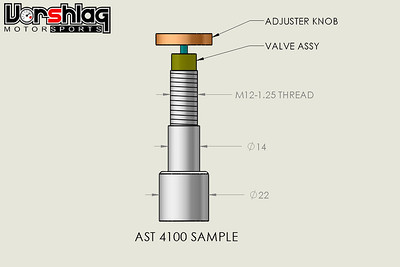

The type of adjuster assembly is crucial (left) as is designing the proper body and shaft length for the application (right)

Sometimes long term reliability has to do with the manufacturer, and how they design and build their shocks, the seals they use, the assembler's care that day. There are a lot of crazy tight tolerances on dampers, and its easy to have a nick in a plating, or a tolerance off, a seal installed backwards, or a whole pattern of issues. Sometimes there are some weird adjuster mechanism designs that are more prone to sticking or breaking. Or shafts that have poor chrome finish, which can cause leaks. Internal bushings and seals are mostly very good in higher end monotube shocks, but the overseas sweatshop stuff is usually pretty poor. Flexing in the strut housing can cause adverse wear, and the wall thickness in the housings can vary from company to company. There are so many factors that it could fill a book...

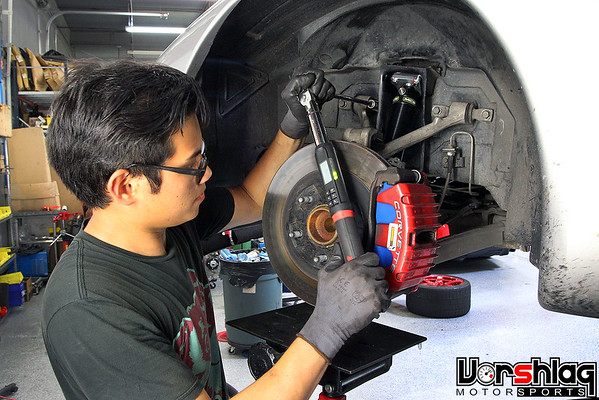

A serious off-track incident can usually mean you have one or more shocks to rebuild...

If a shock is designed with the right amount of stroke (not as easy as you'd think) and installed in a manner that won't allow it to bottom internally (which can cause over-pressure situations and/or damage mechanical parts), normally you can get 3-4 years between rebuilds on a quality monotube damper. That's assuming normal racing use, no crashes, etc. Some folks like to jump curbs and that affects wear. Sometimes people crash, which can blow out one more more damper seals. This happened to me in my Road Atlanta off track incident last year (above), and two of the MCS RR2 dampers on our Mustang had leaking seals that had to be replaced after this event (but were otherwise perfect). I bent two front wheels badly and flattened a tire, as well as a fractured vertebrae - it was a big hit, but the shock repairs were two $10 seals and some fluid.

Daily driving on monotubes can be done, but these conditions can be as harsh or worse than track conditions, when you consider potholes and poor roads. Some folks are attentive and can avoid big road heaves and potholes better than others, and they tend to be the folks who don't jump curbs on track every lap, too. Yes, even in the age of "blame everyone else", sometimes we have to take responsibility for our own actions. Driving style can very much affect the life of any part on a race car, especially dampers. I'm owning up to this myself, and just wish customers would tell us when they crashed or had an off and we're doing a shock rebuild. "Hmm, wonder why this shaft is bent...?"

Hey, stuff happens on a race track and even on the street that is sometimes (but very rarely)

completely out of our control.

So "rebuild interval" estimates are complicated to answer, but it mostly depends on the shock design, machining tolerances, seals/O-ring designs, intended use (rally vs road race vs street), and manufacturer's build quality - but also it on the end user's installation, how they are driven, and the conditions you put them through. Everyone should inspect their monotube dampers for

visible hydraulic leaks before and after every race day, and remove them and check for Nitrogen fill 1-2 times a season (easy - remove, compress, see if they extend under gas pressure). Many monotube designs have user-serviceable Nitrogen fill ports as well.

Since we have rebuilt or installed a

lot of different brands of shocks over the years at Vorshlag we get to see all sorts of brands and issues, after which patterns and trends can be seen. We use these experiences to help us determine which brands we want to sell, install, and help develop new applications for. Cost is also a factor, of course, as there are some really high end brands we don't carry simply because they are hard to sell to our customers. Its all part just of the equation...

Hope that helps?