Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

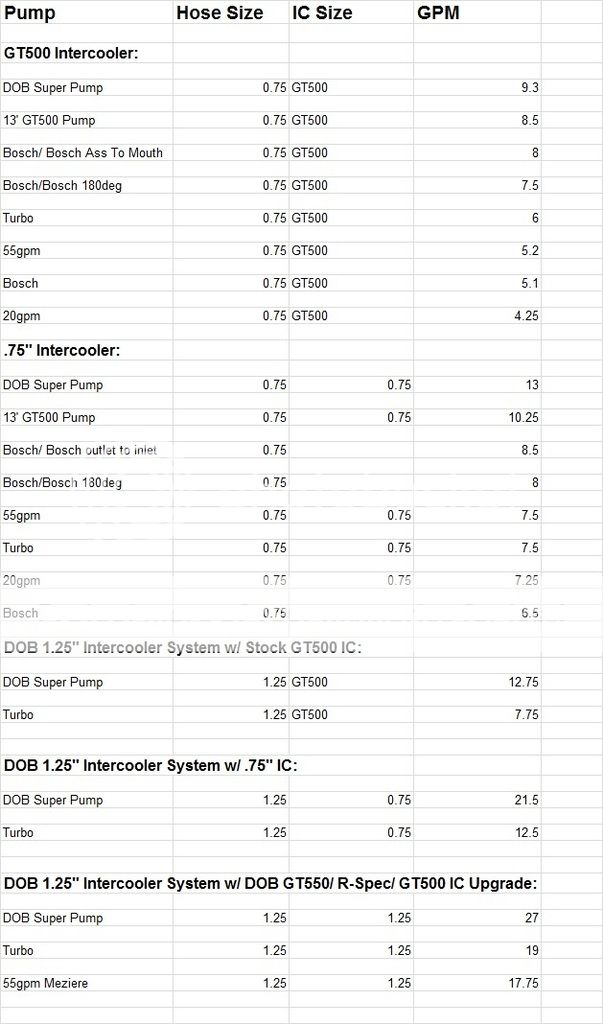

Intercooler Water Pump Flow Data

A Comprehensive Test

A Comprehensive Test

Alrighty ladies and germs. I think it’s safe to say this is the most comprehensive IC water pump test ever done.

It’s pretty clear that there is no such thing as “The Best Pump”. What you want to use will depend on your specific combo, your future plans and your budget.

After all of this testing combined with how we are seeing certain flow numbers perform in real life I’m confident in saying that you can’t have too much water flow. We’ve been testing our S550 at 19gpm a lot this season. It works incredibly well, way better than anything we have ever seen. But it is by no means anywhere near enough to absorb/reject all the heat coming from the blower. So 19gpm is still not getting to the “holy grail” which is a zero IAT rise under boost. So if you’re thinking “10gpm is good enough for me”. Think again. You want everything you can get. End of story. And right now the most we have been able to get is 27gpm.

Don’t forget water flow is paramount. You can have the largest heat exchanger in the world. But if you don’t move the water in/out of the IC fast enough you will have high IAT’s. It’s as simple as that.

We just hooked up with Stewart who makes the pump that Lingenfelter hot rods and then sells under their own name. Stewart is now hot rodding the pumps and selling them themselves (I’m sure Lingenfelter is thrilled) for get this…..$100 less ($450). I’m setting up as a Stewart dealer right now so I will be selling them direct. Right now I’ll call them the Department Of Boost Super Pump because well, they’re super and I don’t have any better ideas. I’ll probably have a group buy going on these soon so save you pennies.

Now For The Data

I didn’t include all of my test data, just the stuff that is relevant to you the guy on the ground. I have a lot more data on different combo’s, line sizes, etc. But none of that is really applicable to you. It just gives me a better idea of what works and doesn’t when looking at the big picture. It also allows me to make educated guesses about other combo’s not tested.

I have two main portions of test data. The GT500 IC/.75” line size date and the .75” IC /.75” line size data. This is what will be applicable to most of you. But it won’t be spot on. Most blowers don’t have a true .75” IC inlet/outlet aside from our GT450. On the flip side not many blowers have a IC that is as restrictive as the GT500 IC is (.55”). So to figure out how your system will perform will take a little guess work. You can take your IC fittings ID and see where it sits between .55” (GT500 IC) and .75” (GT450) and get a pretty good guess where you will sit. For example, if your IC fittings have a ID of .65” (half way between the GT500 IC and the .75” IC) you will flow a number roughly half way between the GT500 and .75” results.

Example:

You have 5/8” (.625) IC fittings. You take the GT500 IC number for the 13’ GT500 pump (8.5) and the .75” IC with the same pump (10.25). Half way between those numbers is .65”, which is really close to .625” and this is fuzzy math so you end up with 9.375gpm. You could build an equation if you want to get down to brass tacks. But this is fuzzy math anyway. Why kill yourself?

Upgraded System Options

We are working on, and will have done soon, upgraded intercooler system packages for the S197. They really are built around the use of our GT550, R-Spec, GT500 manifolds and our GT500 IC upgrade kit that are all based around 1.25” passages. The IC system kits (HE, degas tank, pump, hoses, etc) work great on cars that have “small” IC’s though. Bigger lines mean less resistance, less resistance means more flow, more flow equals lower IAT’s. Additionally the HE’s are MASSIVE:

-Stage I Heat Exchanger – Core frontal area 360sq in. Core volume 540cu in. Can be used with 16” fan.

The Stage I has the largest frontal area of any HE out there (25% more). And frontal area is good. Really good. It also allows the use of a 16” fan which pushes a whole lot more air than two 10” fans do. This will be the “go to” stage for most people. It has a big face, it can use a fan and it doesn’t get its core volume by making it really thick. The core is only 1.5” thick. That makes it easier for the air to get though (opposed to spilling around the sides). We have used this design on our 2010 GT shop car and 2015 GT shop car. They work great!

And most importantly they are set up for 1.25” fittings (you can go smaller though). If you want big water flow you need that fitting size. No other HE is even close. The biggest have .75” fittings.

-Stage II Heat Exchenger - Core frontal area 360sq in. Core volume 1080cu in. Can’t use a fan.

The Stage II has the same frontal area as the Stage I. The only difference is that it’s “double thick”. This big bastard will barely fit and you can’t run a fan. It’s so thick that you really want to “fence” it in also so it drives as much air though the core as possible. This is a no holds barred HE. We don’t recommend it for builds that aren’t toward the crazy end of the spectrum. Depending on interest we may not even make them.

The Point???

What is my point? It’s this. Your goals should determine what pump you use. For example:

If you are currently running your blower with an as delivered IC system you will want to upgrade some or all of it at some point. None of them do a very good job with IAT’s out of the box. How you upgrade it and what components you chose are going to be based on where you want to end up.

If you simply want to put a off the shelf big HE and pump on then call it quits your best bet is to run a 13’ GT500 HE and a 13’ GT500 water pump. That will get you a really big HE and the most cost effective pump for that combo. It will work much better than what you have and it will not break the bank. But, if you think you will ever upgrade it’s not the best choice.

If you go with the 13’ GT500 HE (or any other for that matter) there is an argument for using the DOB Super Pump. For starters it will push more water (about 20%). Secondly if in the future you upgrade to the DOB IC System the DOB pump will “step up” to the task where the 13’ GT500 pump won’t. The DOB IC System/Pump will get you about 17gpm (half way between the GT500 and .75” IC numbers). The DOB IC System/13’ GT500 pump will get you about 10.75gpm. If you think you will ever “go big” the DOB Super Pump is the way to go. It only costs $150 more and it will “grow”. And you will always be able to sell the 13’ GT500 HE for you what you paid for it.

So think about what you will be doing in the long run and choose accordingly.

Chart Key

-DOB Super pump = Stewart/Lingenfelter

-Turbo Pump = Davies Craig EWP150

-55gpm = Meziere 55gpm

-20gpm = Meziere 20gpm

-13' GT500 Pump = 13' GT500 Pump

-Bosch = 07-12' GT500 and just about every blower kit out there's pump

-Bosch/Bosch outlet to inlet = Two Bosch pump run in series. One directly feeding the next.

-Bosch/Bosch 180deg = Two Bosch pumps run in series on opposite sides of the system (not feeding each other). One before IC, one before HE.

>>>Coming Soon<<<

Mathematical Modeling Showing The Effects Of Water Flow On Intake Air Temps

Mathematical Modeling Showing The Effects Of Water Flow On Intake Air Temps

Last edited: