When I was troubleshooting my fan circuits (intermittent operation/wouldn't come on when they should) and wanted to determine if my PCM was working (sending ground signals to relays when they were supposed to) Lito sent me a tune that turned the fans on at 40 deg (essentially "On" all the time). Given everything else was working running that tune turned the fans on as soon as the car was started and told me those circuits were operational. That helped me narrow down the problem to an old fan drawing too much current. Replacing the fan with an FRPP unit and reloading the previous tune restored everything back to normal operating parameters.

Checking if the circuit is coming on "exactly" when it should is a bit of a guessing game so to make it easier I would recommend adding a temp sensor to help you monitor operation. My normal operating parameters show that my low speed comes on around 214 and then cools down to 200 (monitoring the temp gauge) before kicking off. Never really see it hit high operation.

Oil pressure/oil temp on the left. Water temp/voltage gauge on the right.

View attachment 80633

Temp sensor added to radiator upper hose.

View attachment 80636

The key is that a

tuner sent you a

known fan cooling profile that you

have knowledge of to use in your PCM to know what\how the PCM would react to then check all the mechanical aspects of the system to know if the mechanical aspects are functioning as they should or not..................from a mechanical POV.

This still doesn't give you the tune side of this until you have the actual operational PCM fan control settings profile info in hand to then know that your issue isn't being caused\created thru the software........

IMHO this should be a

requirement for all tuners to give the customer at least a copy of the actual fan speed control settings profile being used in the final tune so that the customer can\will know what\how this is set up to then have an expectation of how this will work....period. This is too important for a customer

not to know.

It's 1 thing to burn the BEC terminals when you already know the PCM fan control setup is intentionally set up to run the system outside of it's design intentions beforehand......it's a whole 'nother situation to intentionally put a customer in this position w\o the customer's

consent or knowledge of it............regardless of who does the tuning!

This happens FAR too often than it should be.

My tuner gives me a copy of my actual entire tune file already translated so that I can open it up in HPTuners VCM Editor software so that I can see it all.......cause according to my tuner, "You paid for the tuning & it's your car thus it's your tune. I could care less as to whomever sees the file. I have found that in the end, I end up getting more business from doing this cause it sends the message that I am very confident in my abilities to tune & isn't worried about any competition. I got nothing to hide."

His exact words. He keeps a copy of them for his records as well.

This is how I caught this w\ my car.....by using HPTuner's tune file comparison feature to compare my car's tune file w\ a sample '05 OEM SO tune file that comes w\ HPTuners VCM Editor software & saw that this had been changed to do exactly how Lito set up your "fan system checking" file.....my tuner didn't touch this part BUT Bama certainly did cause it was the Bama tune my tuner used as the base file (I had it already loaded in my PCM) & since we wasn't having any issues of overheating during the initial dyno session he assumed that all was good so didn't even look at it.... The only reason I had the Bama 91oct tune loaded up back then was to see how it would perform after I burned all the 87 oct fuel out the tank to fill up w\ 91 oct fuel prior to my dyno session at my tuner's direction (I used the original OEM tune set up for 87 oct fuel w\ the SCT Options set in it to use the FR Bullitt 85mm CAI, BBK 62mm TB, FRPIM & Kooks LTH's w\ cats so the rear O2 sensors enabled) & forgot to flash it back to stock.

Good thing for me is that I caught it all well before I began to have any of the symptoms even show up.

This is why I brought this up to bring this attention to the OP (the rest as well) because of what he typed as clues to this being a cause of his symptoms & shouldn't be overlooked.....

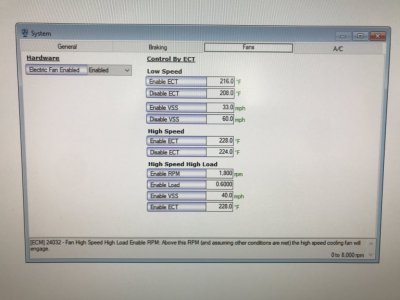

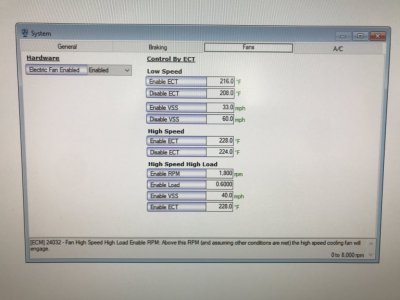

PS--for those who want it, here is a picture of an OEM fan control profile in a SO PCM for 05-09 GT taken in HPTuners VCM Editor:

Also just to point this out.......the low speed fan ECT target on\off settings you see in this picture represent the Ford designed\intended optimal thermal operating range for this 4.6L 3V engine......thus best efficiency out of it.