Looks good BJ!

Couple things:

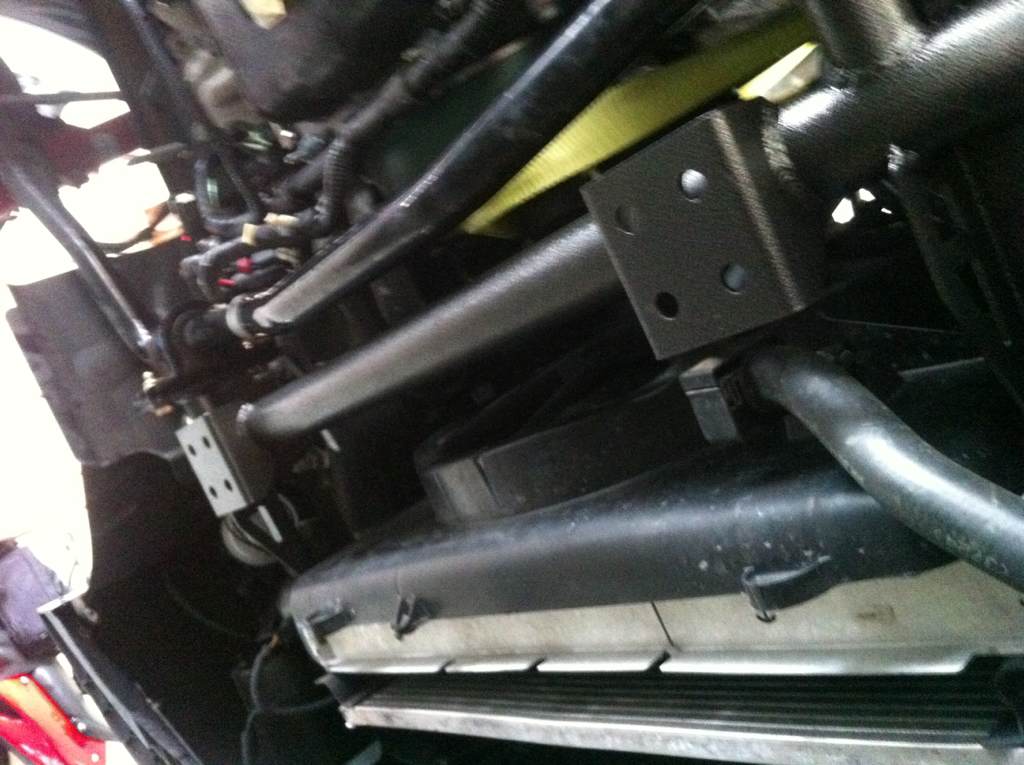

-You can install the the Rack first, then the A-Arms. That is how we do it. You have to install the bolt from the back of the car, towards the front (opposite of how you have the bolts) I do agree though, we probably should not recommend the rack going on first, OR we should tell them to install the bolt from the back.

-Some advice, swap the rack bolts around, to where the bolt-head is on the bottom/k-member side, and the nut on the rack side. It will provide you with more clearance, and it looks much cleaner, IMO.

-One of the primaries is hitting the a-arm/bracket? Both sides? I apologize for that, honestly, we have not tested your specific K-Member (Shelby 1000 Spec) on a combo with stock arms, as we developed the entire front end package together for the Shelby 1000 application. Please send me some detailed pics to my email sir of the clearance issue.

I am glad you are happy, and yes, there is definitely an increase in NVH with that system. The NVH increase is primarily due to the small poly engine mounts.