Tcochran14

Junior Member

- Joined

- Aug 18, 2021

- Posts

- 4

- Reaction score

- 0

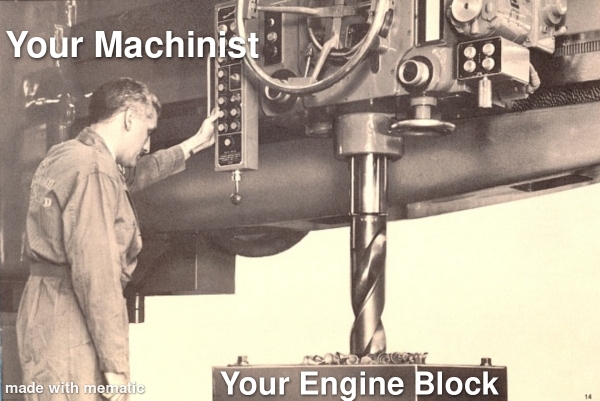

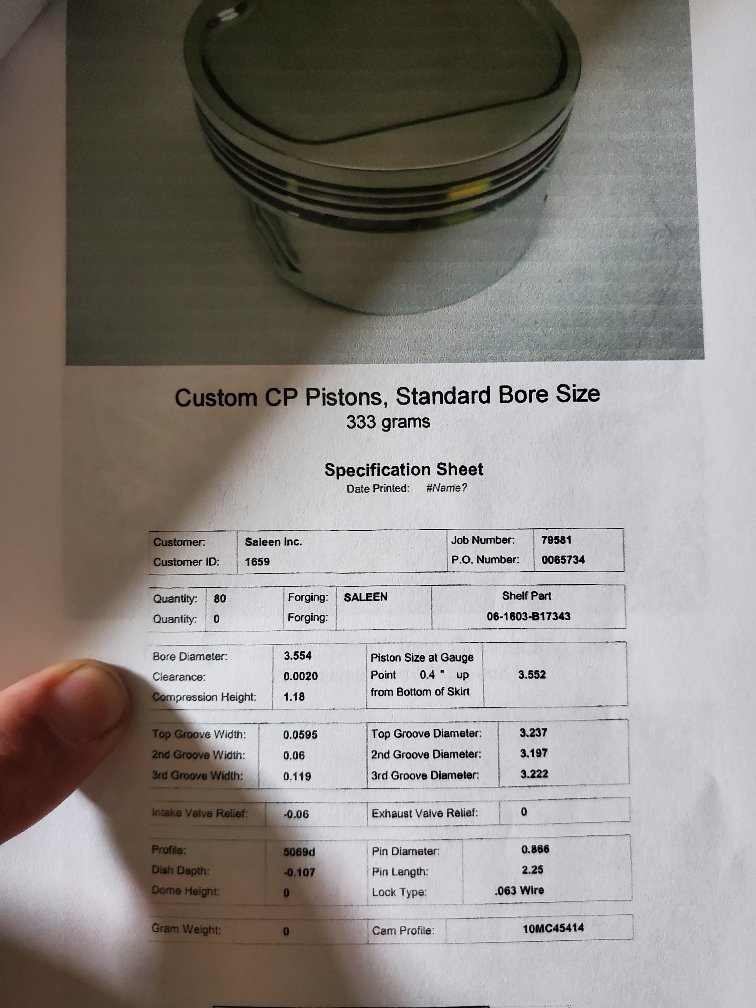

Hello, long time reader first time poster here. I am in the process of building an engine for my 07 GT. I did tons of research, read everything i could find for months, build threads, videos, Sean Hylands book, everything I could find to prepare and make the best decisions the first go round. although I am in need of some advice. I’m running stock crank, manley rods, manley coated pistons, total seal rings with a vortech v2 bolted on the front, plan on 9-11 lbs. (I’ll spare all the build details) I visited several machine shops looking for one with a torque plate. Had them balance rotating assembly, align hone the mains, resurface the deck and hone the cylinders with a torque plate. I discussed with the shop .0035 piston to bore clearance like the manley instructions said. Picked up my block this week and upon measuring everything myself and according to the shops measurements piston clearance is coming in at .0055 across all cylinders. Machine shop says they have built several 3v’s with this clearance and it will be fine. This seems excessive to me. What do you guys think? Will these pistons slap like crazy? Prematurely wear out? I don’t know what do to. Looking for any advice here, I appreciate the wealth of info on this site, it is incredible.