Is it just me or does the foot print on the 315/40ZR20’s look wider than the 325/50R15’s on the left?

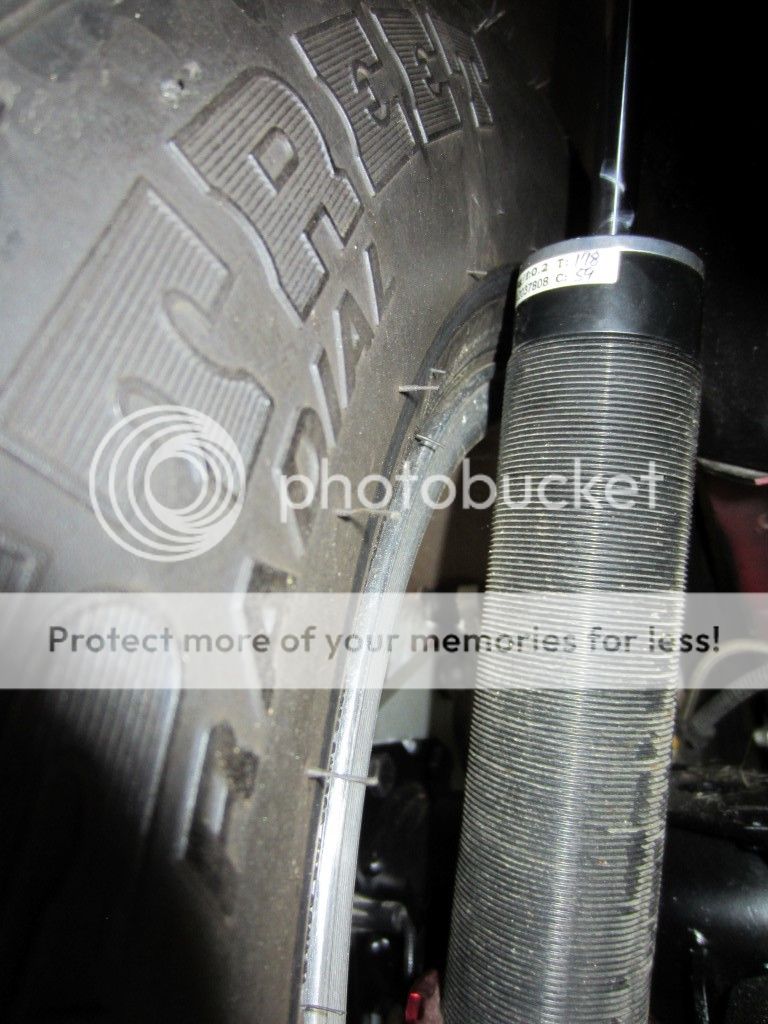

With the 15” Race Stars I needed ¼” wheel spacers to provide adequate clearance with the top of the Air Lift Performance shock body. Albeit the car is up in the air but it does not look like the spacers are required to clear the shocks. Once I drop the car down I will need to check for inner fender tire clearance.

Vossen without ¼” wheel spacers.

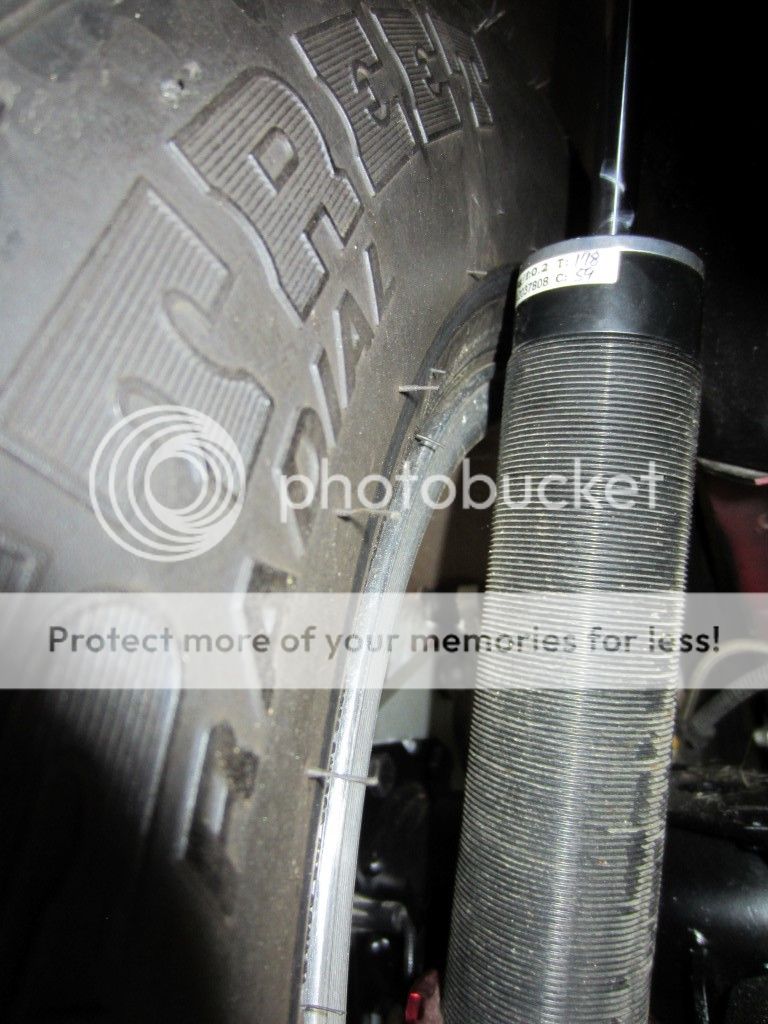

Race Stars with ¼” wheel spacers.

As I expected the OEM size rotors look pretty small. After the rotors pretty much filling up the opening on the Race Stars this is going to take some time to get used to. Not sure if it will ever grow on me!

With the 15” Race Stars I needed ¼” wheel spacers to provide adequate clearance with the top of the Air Lift Performance shock body. Albeit the car is up in the air but it does not look like the spacers are required to clear the shocks. Once I drop the car down I will need to check for inner fender tire clearance.

Vossen without ¼” wheel spacers.

Race Stars with ¼” wheel spacers.

As I expected the OEM size rotors look pretty small. After the rotors pretty much filling up the opening on the Race Stars this is going to take some time to get used to. Not sure if it will ever grow on me!