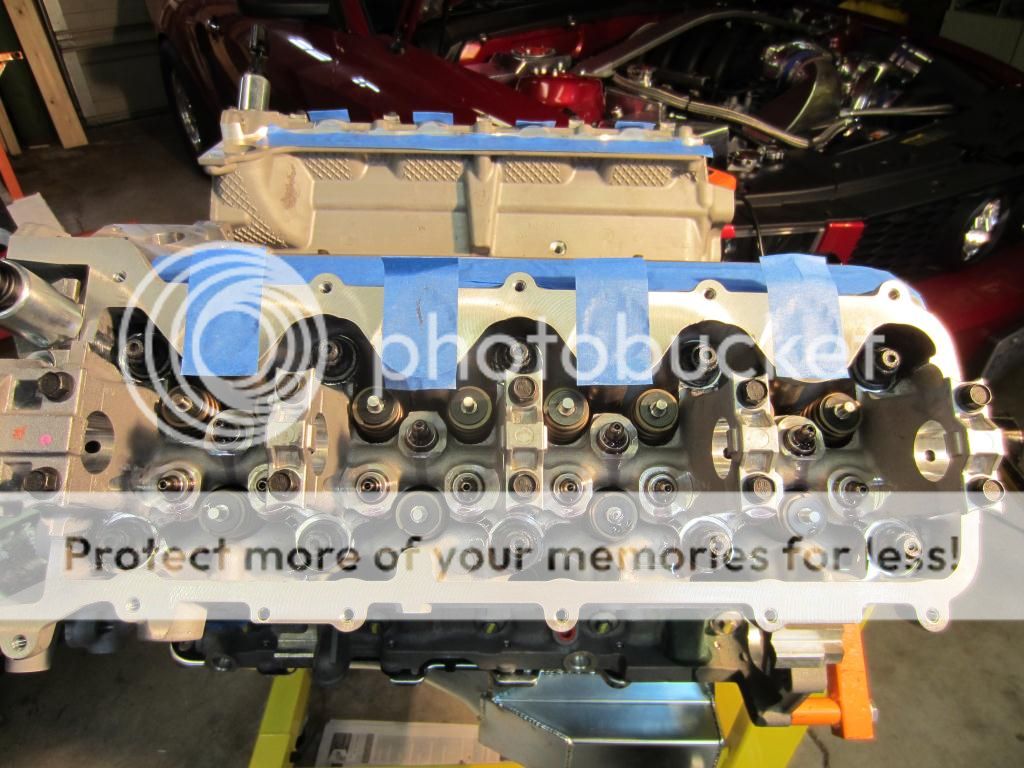

Oil Pump Modification

Thanks to the research by “One Eyed Willy” I am modifying the Oil Pump in my build to further bullet proof the pump. Originally 3V oil pump failures were attributed to the gears, as a solution many builds have gone with TSS or MMR billet replacement gears. I purchased a Triangle Speed Shop (TSS) pump with Billet Gears for my build. However, for the 2013 5.8L SVT motors Ford came out with an Oil Pump # DR3Z-6600-A that has a Billet Backing Plate. The Billet Backing Plate weighs in at just less than 12 oz. while the OEM cast plate is a little over 3 oz. On my TSS Pump the Backing Plate has been replaced with the Billet one from the 2013 SVT Pump.

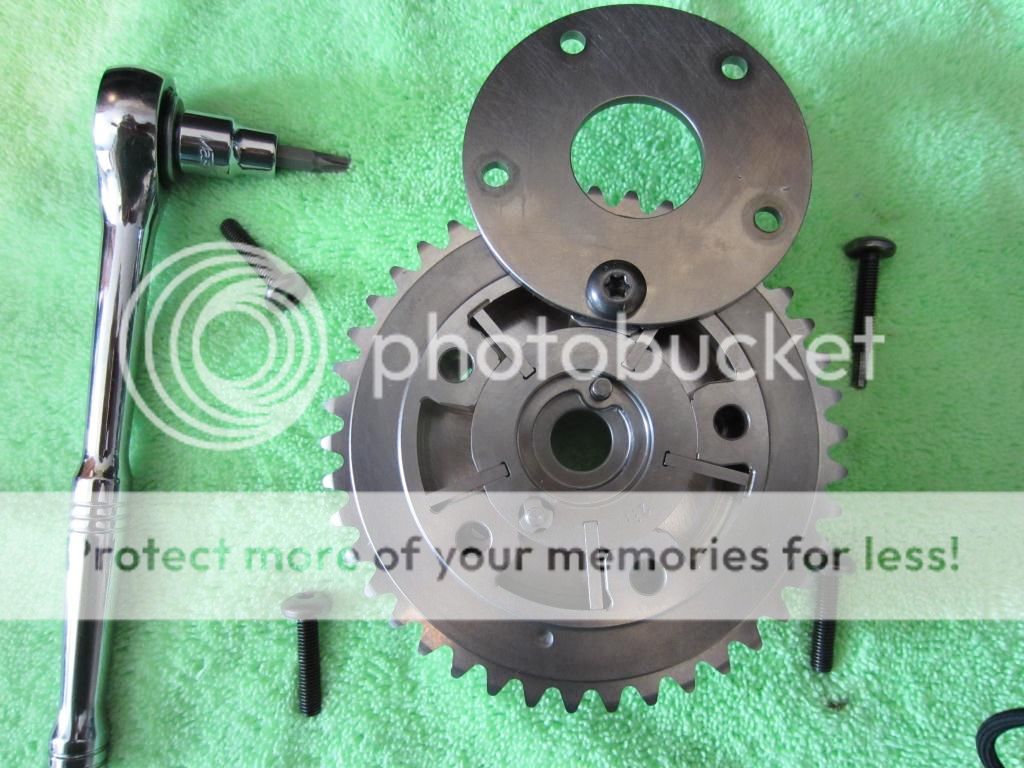

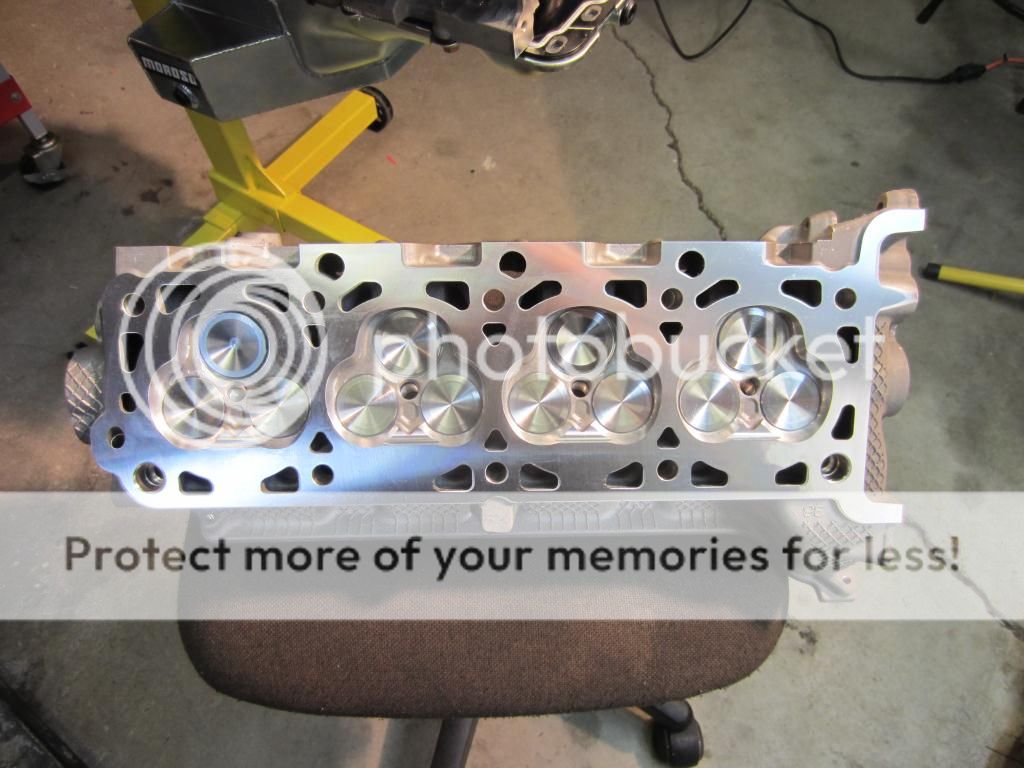

2013 SVT Pump on the top and the TSS Pump on the bottom – with covers on:

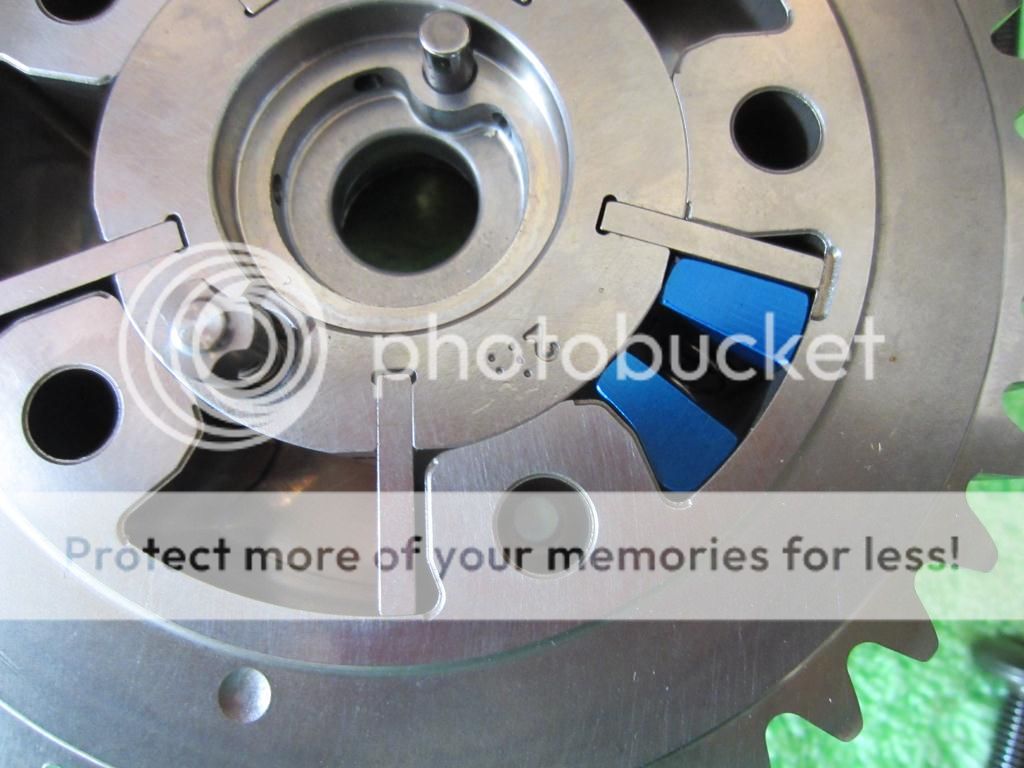

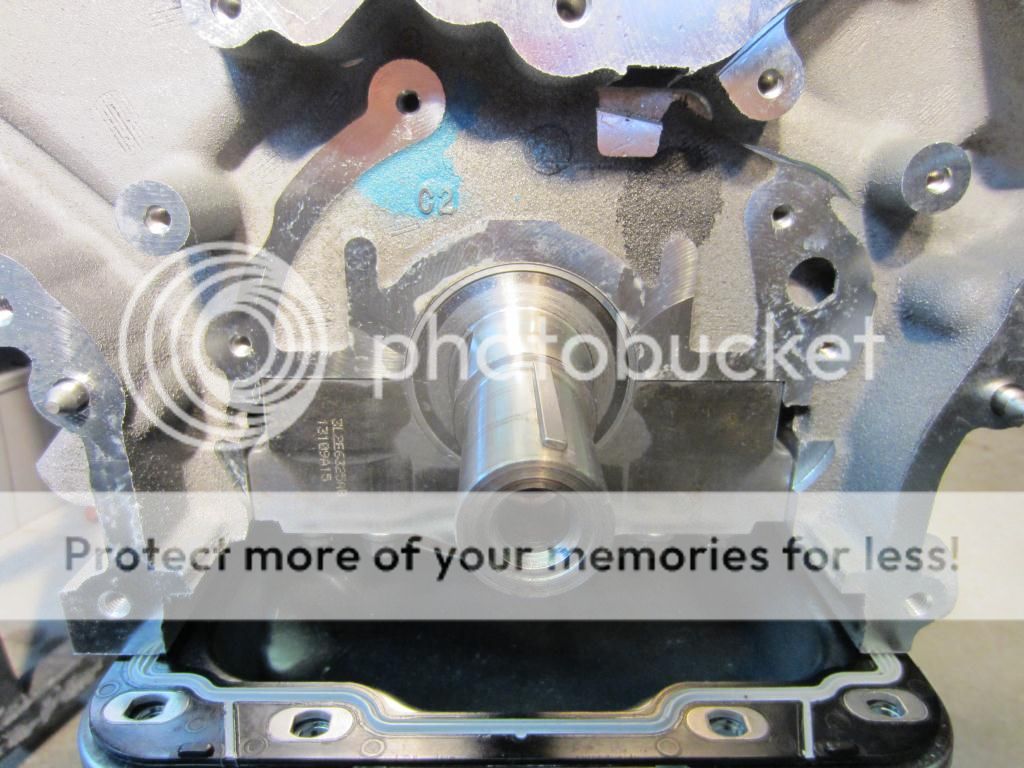

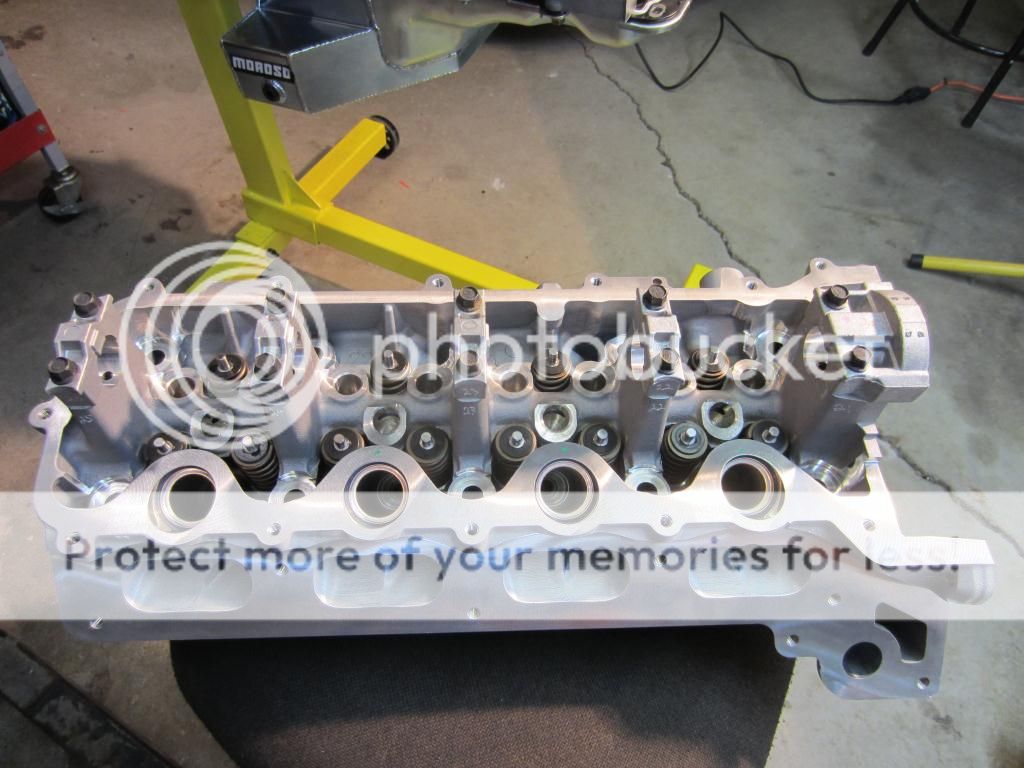

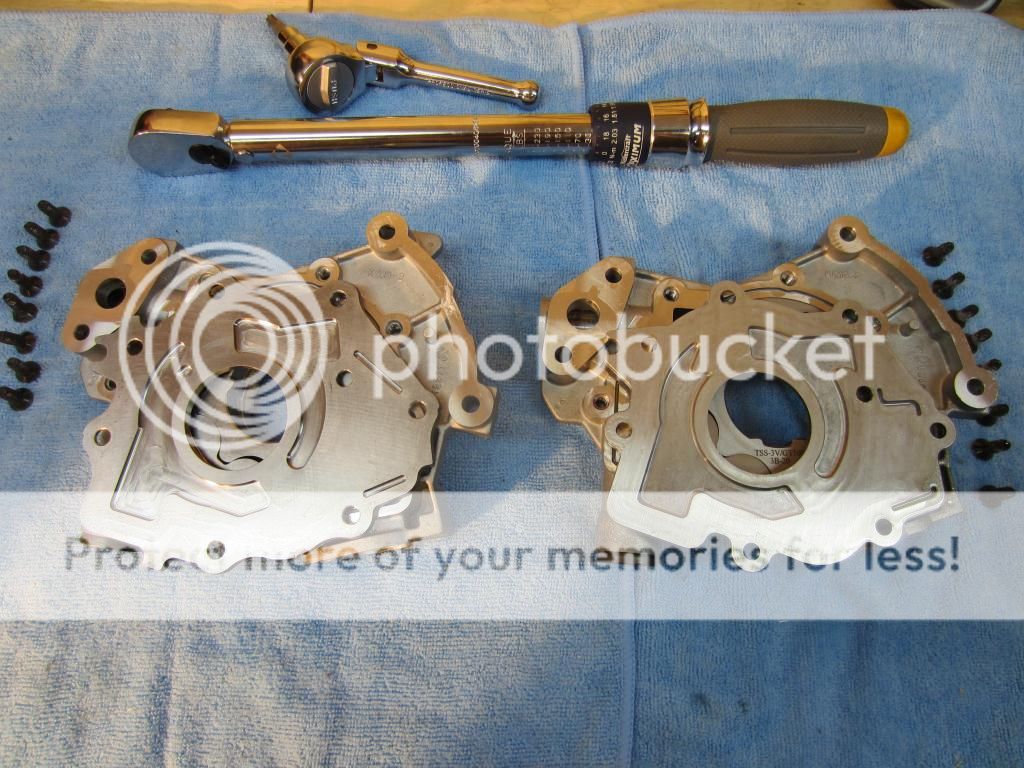

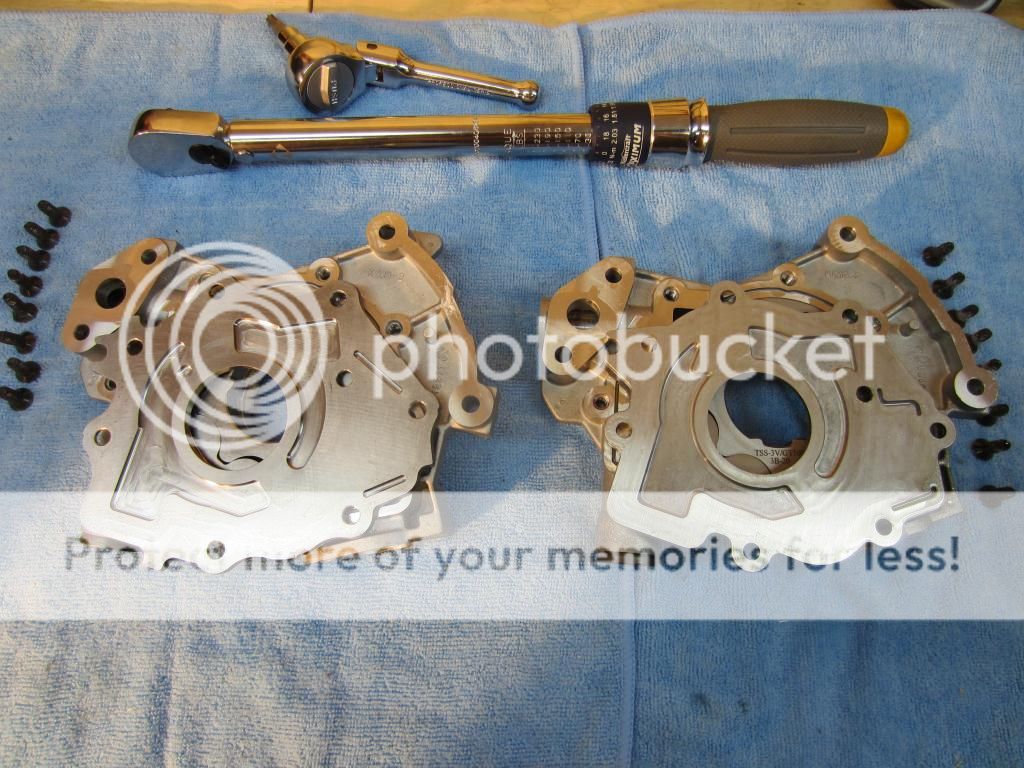

2013 SVT Pump on the left and the TSS Pump on the right – with covers off:

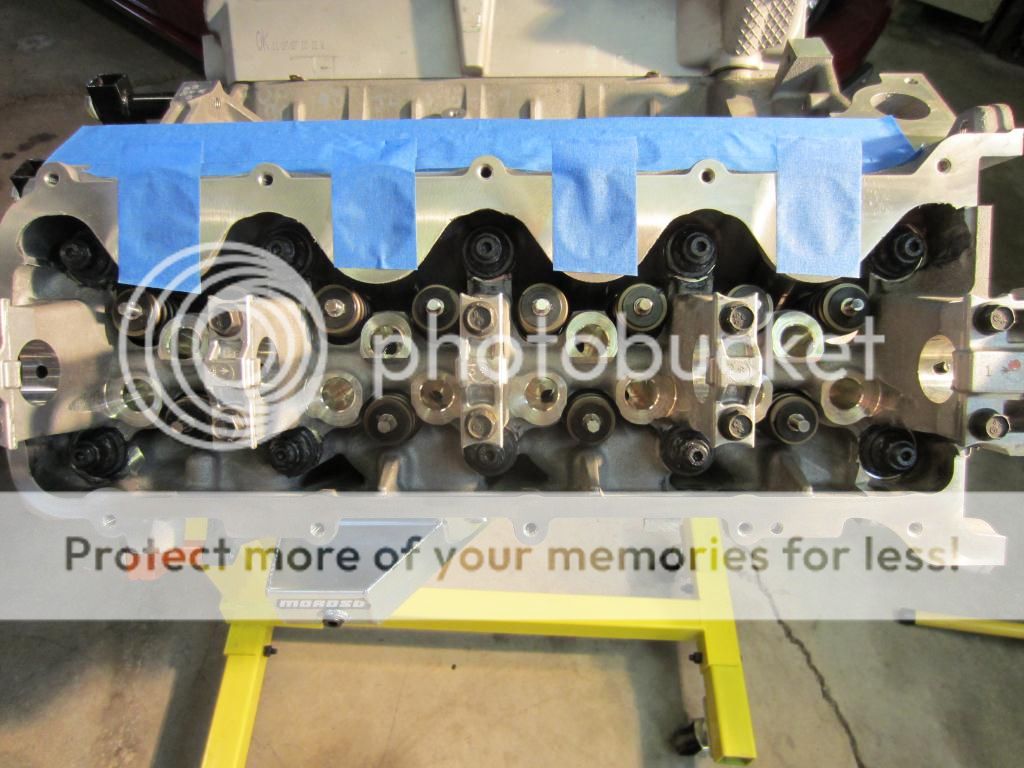

TSS Billet Oil Pump Gears. Noticed That Triangle Speed Shop used High Strength Red Thread Locker on the backing plate bolts so I will use Red in my build as well.

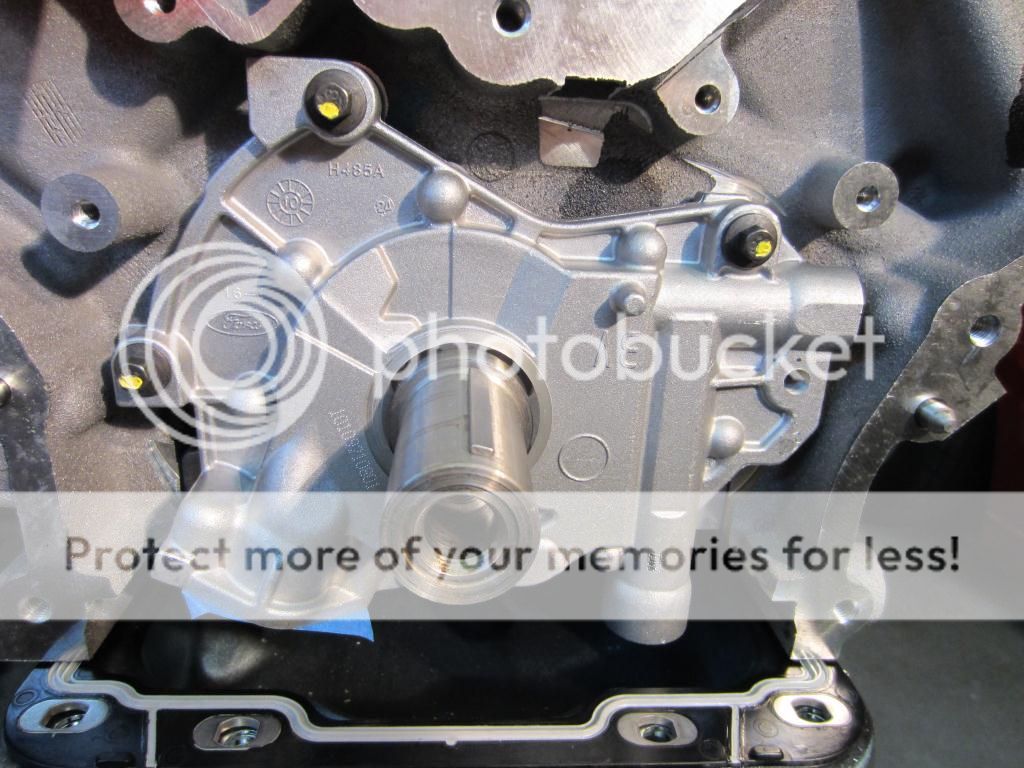

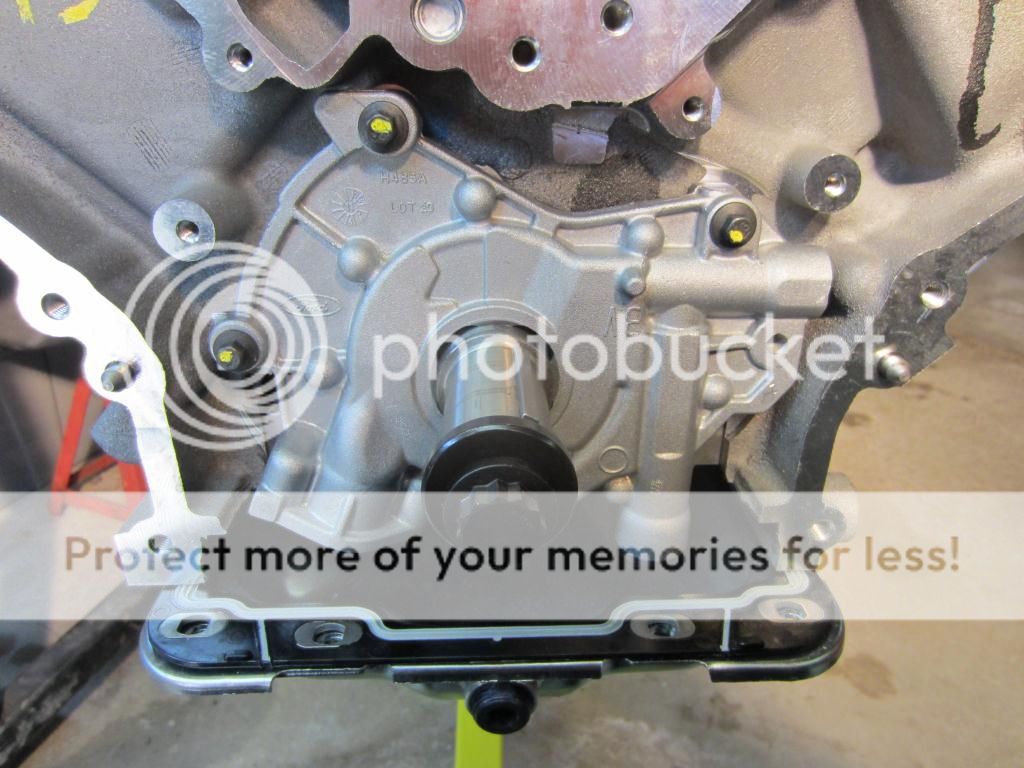

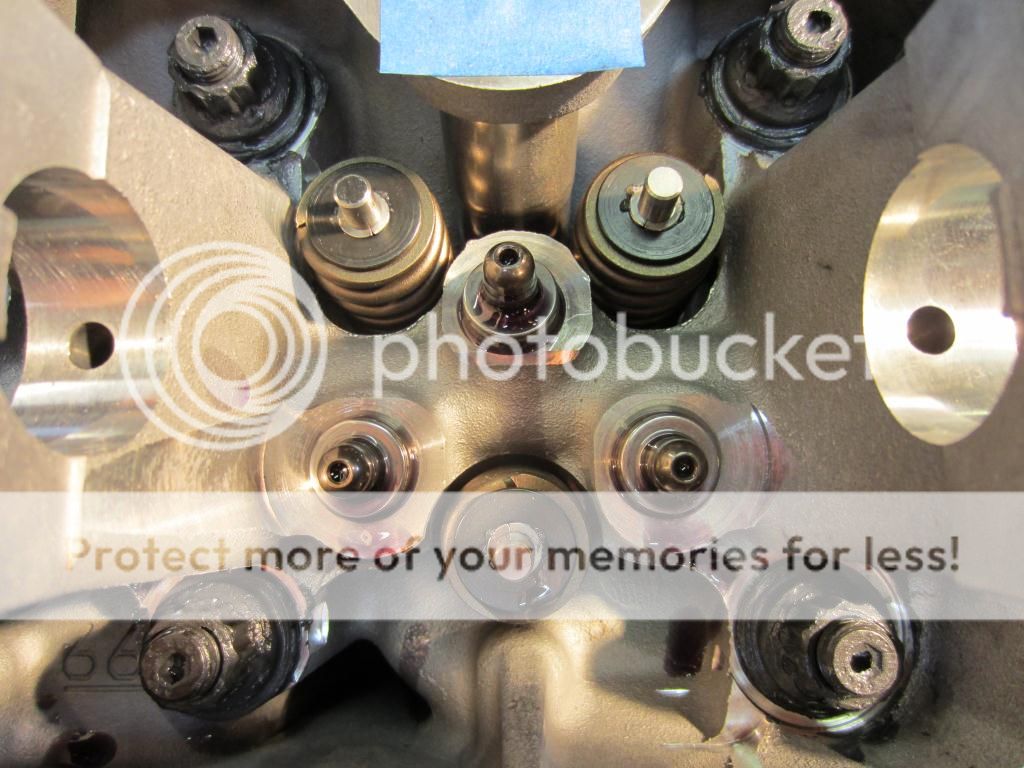

Billet Cover installed on TSS Pump (T30 Bit, torque to 89 in-lbs with High Strength Red Thread Locker)

Thanks to the research by “One Eyed Willy” I am modifying the Oil Pump in my build to further bullet proof the pump. Originally 3V oil pump failures were attributed to the gears, as a solution many builds have gone with TSS or MMR billet replacement gears. I purchased a Triangle Speed Shop (TSS) pump with Billet Gears for my build. However, for the 2013 5.8L SVT motors Ford came out with an Oil Pump # DR3Z-6600-A that has a Billet Backing Plate. The Billet Backing Plate weighs in at just less than 12 oz. while the OEM cast plate is a little over 3 oz. On my TSS Pump the Backing Plate has been replaced with the Billet one from the 2013 SVT Pump.

2013 SVT Pump on the top and the TSS Pump on the bottom – with covers on:

2013 SVT Pump on the left and the TSS Pump on the right – with covers off:

TSS Billet Oil Pump Gears. Noticed That Triangle Speed Shop used High Strength Red Thread Locker on the backing plate bolts so I will use Red in my build as well.

Billet Cover installed on TSS Pump (T30 Bit, torque to 89 in-lbs with High Strength Red Thread Locker)

Last edited: