Locating “True” TDC

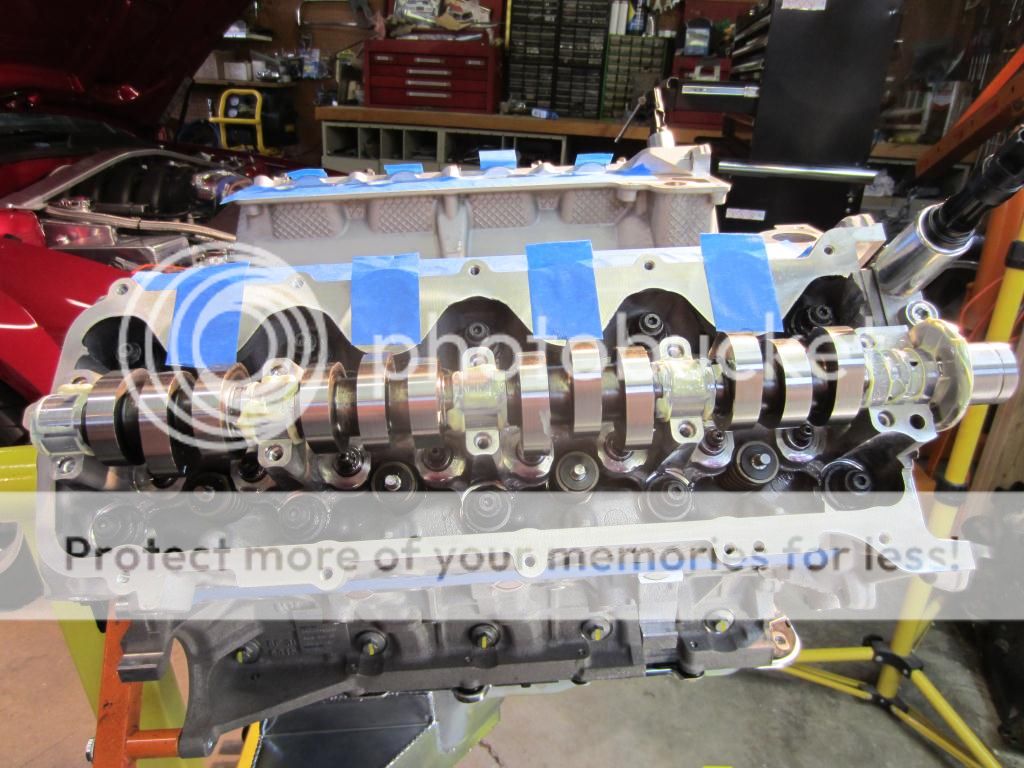

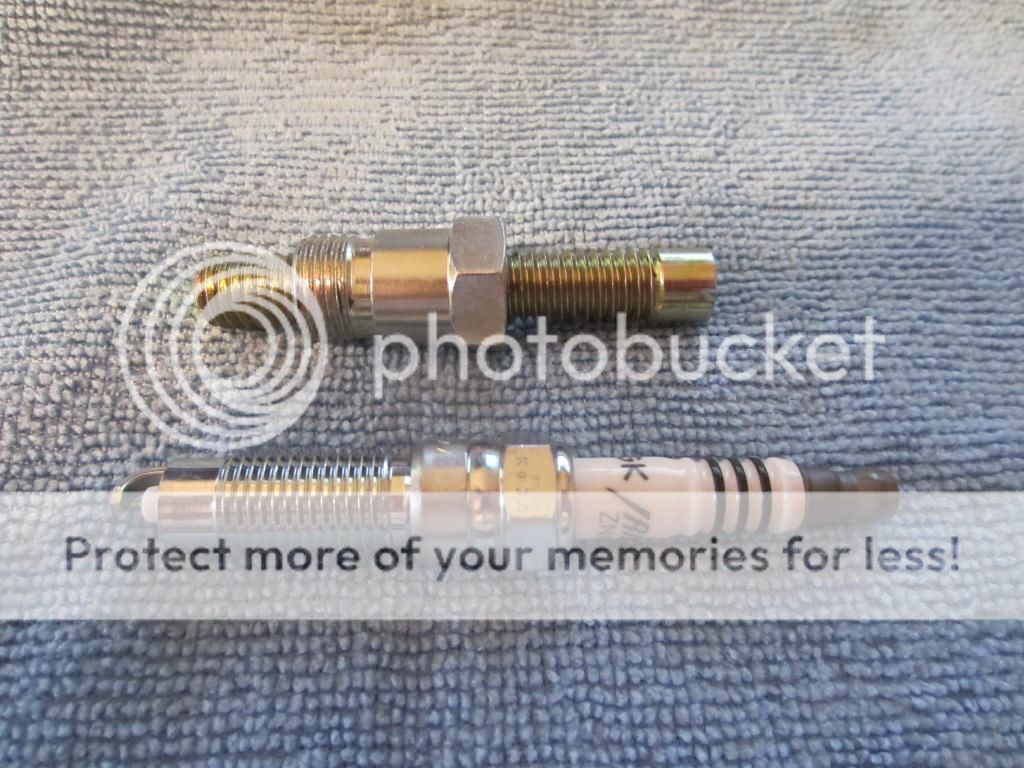

Got back to the garage today for a few minutes and made a little progress, put the fabricated 12mm thread Piston Stop to work.

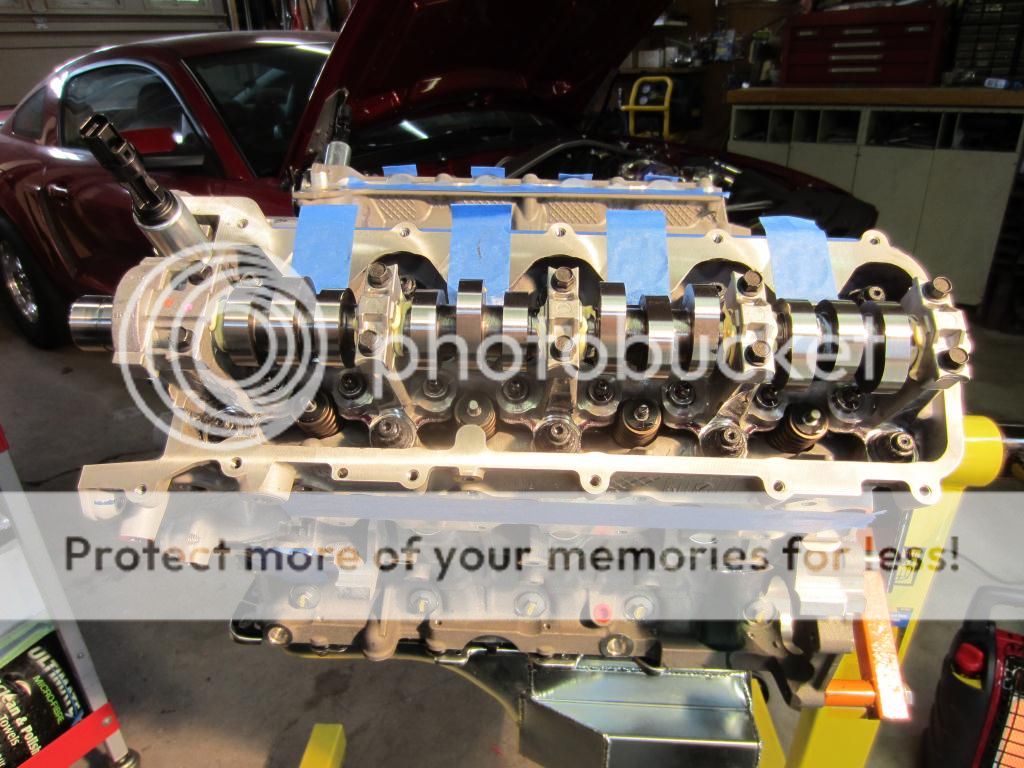

Ok, I have been out of the game for a long time, let say it has been over 30 years since I degreed a cam. So needless to say this is the first 3V cams I have attempted. Basically I elected to follow the Comp Cam instructions.

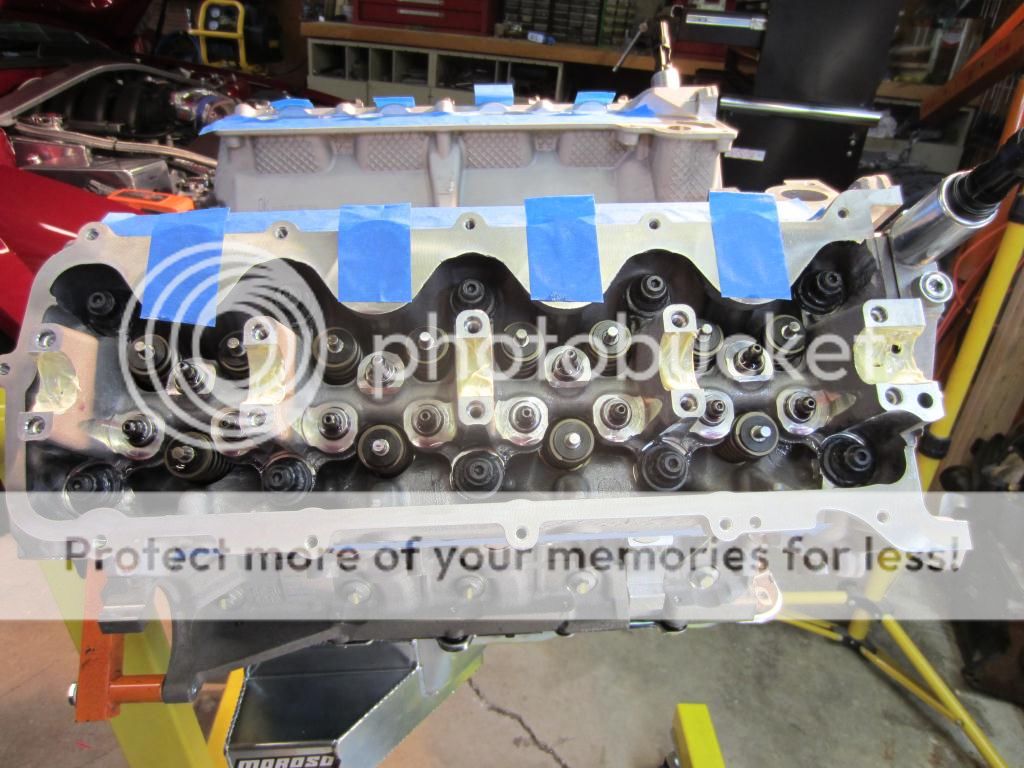

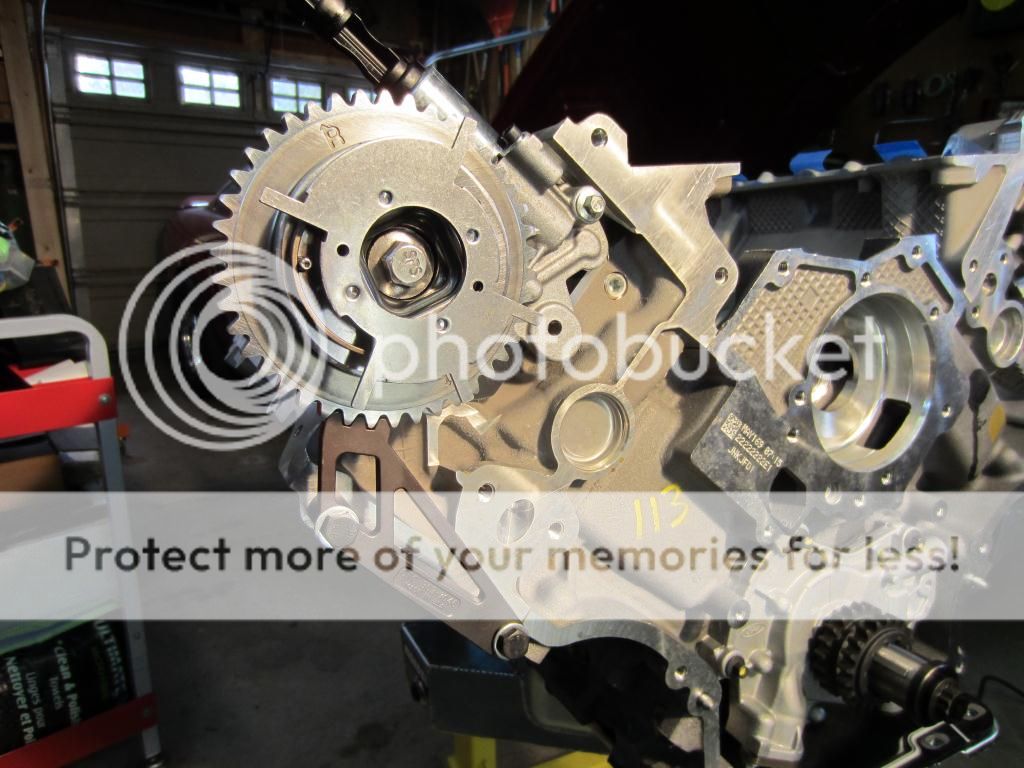

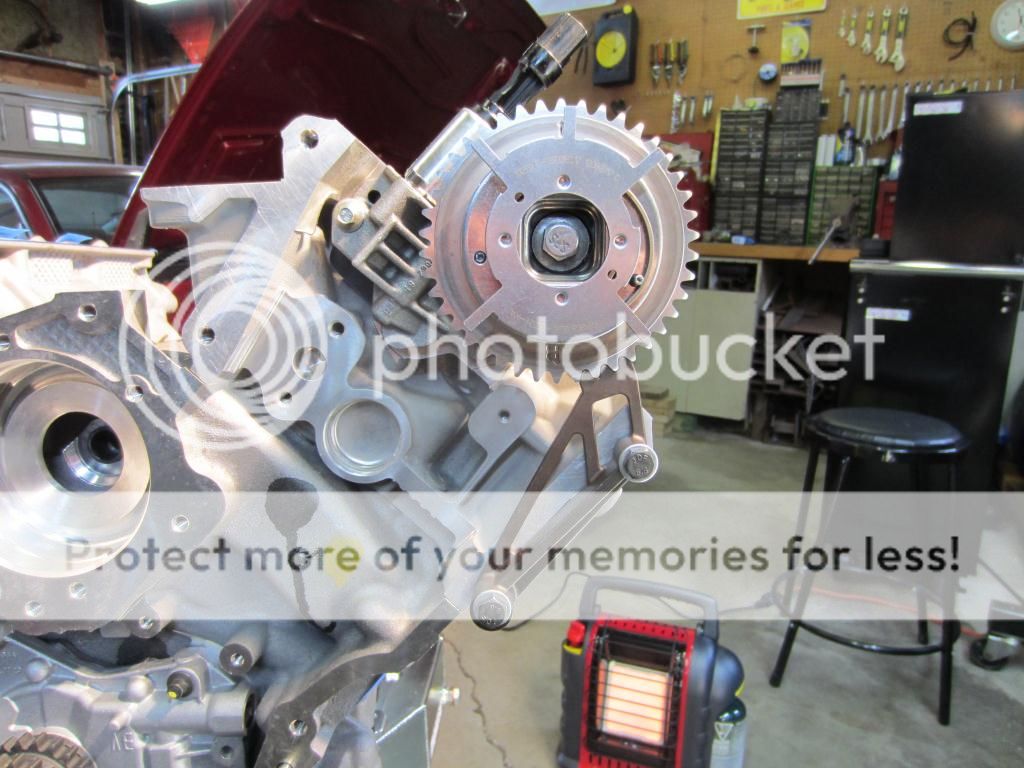

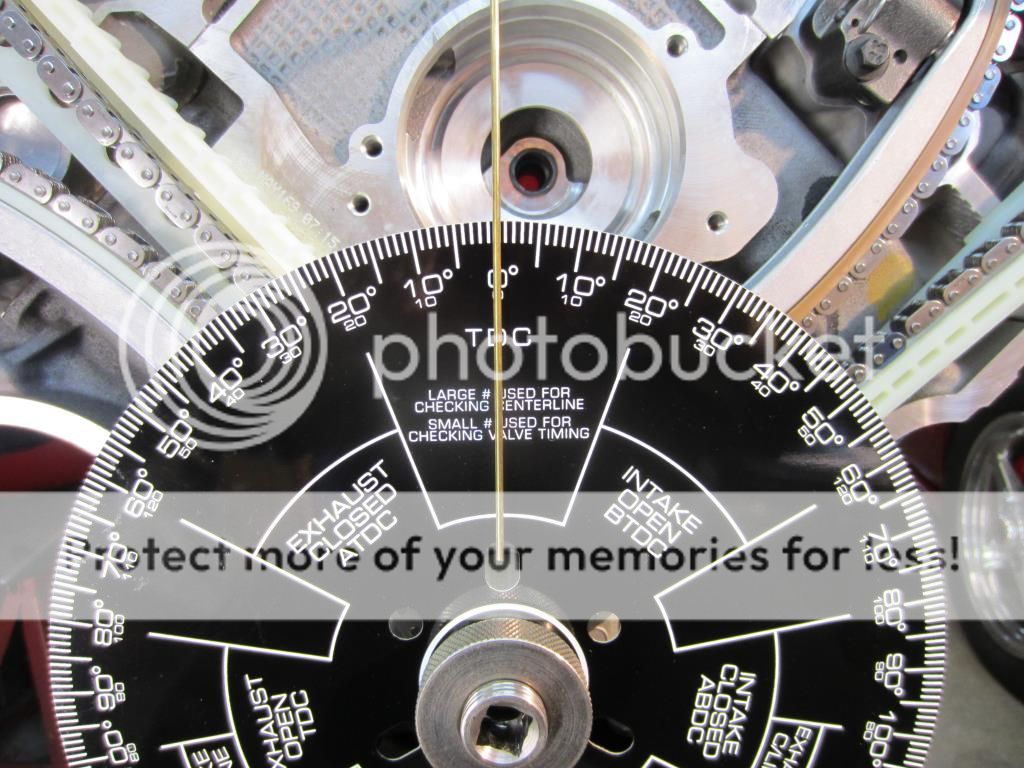

Installed the TFS Degree Wheel and a pointer. The Degree Wheel was set to zero at the pointer.

Engine was rotated counter clockwise 20 degrees and the Piston Stop was installed in #1 spark plug.

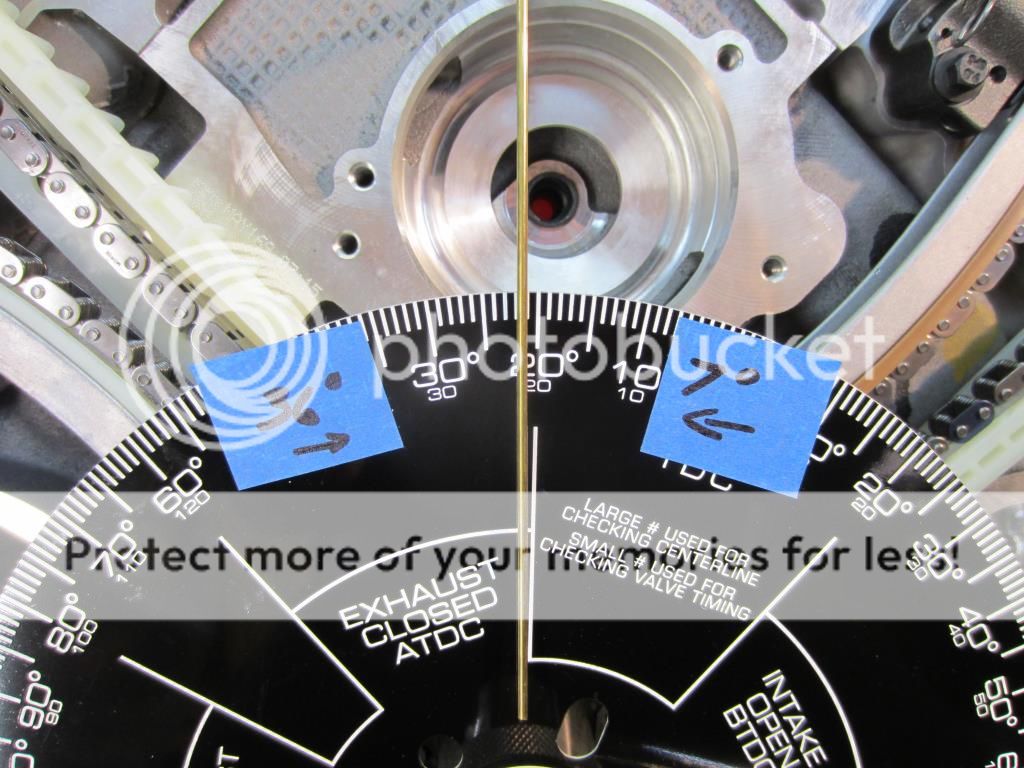

Crankshaft was rotated clockwise until the piston fit the stop at which point the number indicated on the degree wheel was recorded, in my case 7 degrees, “A”

The crankshaft was then slowly rotated counter clockwise until the piston fit the stop in the other direction. Again the number on the degree wheel was recorded, in my case 36 degrees, “B”.

Piston Stop was removed and the Crankshaft was rotated to the midpoint of the two marks on the degree wheel. In My Case 21.5, “C” = (“A” + “B”) / 2

Without moving the crankshaft the Degree Wheel was relocated to zero degrees at the pointer.

To be sure I have located true TDC I will repeat this process next garage time and then on to checking the cams. I want to do Cylinder #1 and #6 since they are both at TDC at the same time.