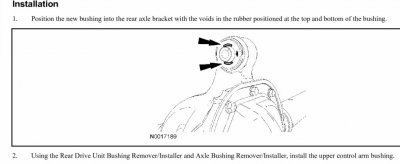

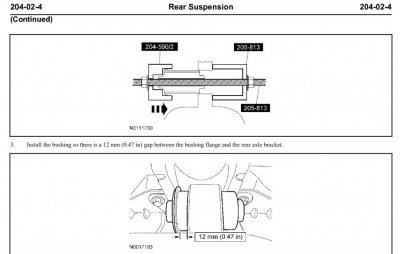

I just want to be clear on something you said. Am I correct that you were saying that the voids (open slots) in the bushing should be at 12 & 6 o’clock ? Also, I can’t find it in this thread, but I think you mentioned a gap between the Diff housing flange, and the bushing flange to get proper center. Do you remember that measurement?

Here ya go...........

Ford Workshop Service & Repair Manuals - fordrepair.info - 2011 Mustang Rear Suspension Upper arm bushing (iihs.net)

This is the same for all 05-10 S197's as well. The removal\install tool shown is the Ford Rotunda tool w\ the particular part #'s for each pertinent part. This tool is hella expensive (was $657.95 + shipping\tax when I bought it some 4 yrs back) & is not the easiest tool to find\acquire (I ordered it thru my local Ford dealership as they were the only point of access, I could find in my area.....) but you may be able to rent a similar type of tool from your local AZ, O'Reilly's, etc. It is this Rotunda tool that will automatically set the proper gap to center this bushing in the axle housing when it bottoms out, once you initially set the bushing articulation slots in the proper orientation (vertically in the axle.....the 2 flat sides in bushing outer shell flange are also alignment guides).

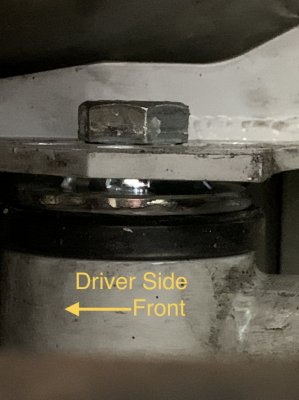

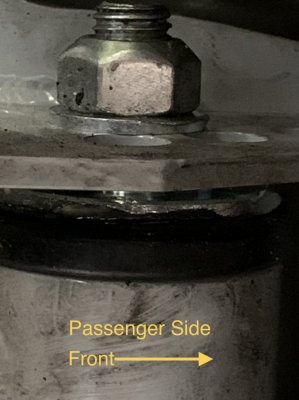

Here are a couple of pics showing the “After Install” results. Since you have downloaded the somewhat jacked-up install docs, you’ll notice my UCA mount is slightly different than the instructions show. Mine has an extra hole which is higher, and further back on the mount. I ignored that hole completely. (Pic #3)

Also, I’ve been thinking about the flow of the install that day, and I’m wondering I’d perhaps the adjustment is indeed off a little. If the arm is too long/short for example, that could be preloading the arm in one direction or the other, and allowing a more constant pressure on the bushings that would aid in transferring more NVH when unloaded. I mention this, because even when the howling present, hitting the throttle to induce heavy load, reduces the noise substantially. It generally only intolerable when cruising with no load in 6th. Acceleration or deceleration takes most of it away.

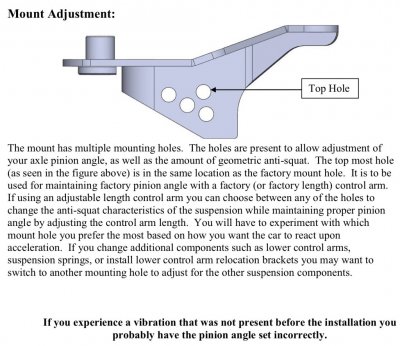

Yeah, I noticed that as well. From my intuition, that undocumented hole should be the OEM hole for use on a 05-10 S197 (the 05-10 S197 OEM UCA arm length is approx 1" shorter than the 11-14 S197 OEM UCA arm length) so it looks like you installed in the proper hole for 11-14 S197 OEM UCA arm (this sets the instantaneous center measurement of axle in vertical thru the UCA to a spot at front bumper where the line thru the UCA arm intersects w\ the line thru the 2 LCA's (if the 2 LCAs are level at OEM ride height)). By setting the Steeda UCA arm hole center length to the OEM UCA arm hole center length, this should fully realign the UCA to the OEM Ford UCA alignment measurements......including the DS pinion angle for the 2-piece DS & UCA neutral IC.

The larger issue concerning NVH is the relation of DS pinion angle to rear axle flange vs the amount of pinion deflection (droop\rise) when suspension travels thru its compression\extension arc. This will in part be determined by the UCA arm length thru hole centers. This is why DS pinion angle should always be set w\ car at normal ride height (full weight on suspension) & level so the DS pinion angle will be set w\ the suspension at neutral IC (center of suspension travel arc) to minimize the amount of pinion deflection from axle travel.......which will cause a slight change in DS pinion angle when suspension travels in either direction from IC center. When you lower the ride height on these S197s, you change all of this thus all needs to be realigned back to spec to eliminate any issues derived from lowering the ride height.....including DS pinion angle but also IC to correct pinion deflection thru suspension travel (or if drag\road racing.......called anti-squat....intentionally setting IC shorter thus forcing less suspension compression from ride height which transfers more down force to the rear axle thus tires for traction purposes on the throttle hit.....this is what the other holes in the Steeda UCA mount are for).

This is why the 11-14 S197 UCA arm is longer than the 05-10 S197 UCA arm......the purpose is to reduce the amount of pinion deflection during rear suspension travel to offset the amount of change of DS pinion angle from it.

Since the install of the Steeda UCA assembly, this may need to be adjusted a little due to the lack of bushing deflection under load (pinion rise) to bring all back into realignment to reduce the amount of NVH frequency travel rate into unibody (OEM setup will account for this to some extent thru its bushing design). Why I made suggestion to recheck this adjustment while installing the OEM UCA axle bushing........

Also you mentioned an adjustable PHB. I already did an FRPP adjustable to correct any off-center axle issues.

What I'm meaning by bringing this up is when you use an adj PHB to center the axle to the unibody to center up the rear wheels in the unibody tubs, you're also realigning the axle pinion shaft center alignment to driveline center (axle should be perpendicular--90*-- to driveline center--engine crankshaft thru trans output shaft center) at the same time which will\can induce a lateral side loading\deflection to the U-joints\CV joints from being out of alignment. I don't know how many of us actually check for this while you're shifting the axle laterally to align the tires to the unibody......but you should......especially if using a 1-piece DS using 2 U-joints.

This is another reason why Ford used a 2-piece DS w\ 2 CV joints in a half-shaft config instead of a 1-piece DS using 2 U-joints w\ this S197 chassis. When the unibody rolls, this rolling motion will shift the unibody laterally to the axle thru the PHB travel arc away from its center at ride height thus will also shift this axle-to-driveline center alignment away from center causing the same lateral side loading\deflection on U-joints\CV joints which, depending on how much deflection is created, can cause some extra NVH as well.

Why it is a general good idea to install a Watts link along w\ a 1-piece DS using 2 U-joints to eliminate this lateral side loading of the DS U-joints from unibody roll (maintains perpendicular axle center to driveline center alignment as well as the tire to unibody tub alignment).

This is a lot to digest, but you asked for an understanding, so I gave it my best shot.

Hope this helps.