Project Update for August 28, 2013: Been a busy couple of weeks since the last project thread update, with the majority of the new aero work completed on our TT3 Mustang after working long hours every day and night. It was a major thrash to get all of this done in a 2 week period. During that time we also ran an autocross event with Amy driving our 2013 GT (STU) and me in Matt's BRZ (STX), and then track tested the new front aero parts on our TT3 Mustang. We're now in the final week thrash to do all of the "clean up work" to the car before we load up and head 22 hours across country to the NASA Nationals Sept 4-8th, so let's get caught up.

S197 Mustang Coilover Tester Needed in Dallas/Ft. Worth Area

Before we dig into the STU Mustang autocross test results, let's get to the reason

why we went to this event out of the way - to test some MCS coilovers on one of our shop employee's cars, a 2013 Subaru BRZ. And this has a bearing on the S197, too. How is the suspension on a BRZ important to a Mustang? Well, they have several things in common: both chassis have McStrut front/shock rear suspensions, both have a factory coilover spring on the struts, and both chassis Vorshlag makes camber plates for. They also both are RWD, and they share almost the same track width (about the only dimension they have in common). So our suspension testing on the BRZ does sort of apply to S197 Mustangs.

We also sell MCS coilovers for the S197 Mustang, and in fact we have the first TT1 set in stock that we had built to our specs. All we lack is a tester to buy this set, then let us photograph, install and measure all of the parameters we like to check on a brand new suspension option like this. We've done installs on MCS RR2 doubles with remotes and TT1 singles on other cars, just have get a Mustang buyer to let us install a set for the S197 chassis.

Fitting the custom built set of MCS TT1 shocks to a tester's BRZ, sans springs, for bump/rebound measurements

Fitting the custom built set of MCS TT1 shocks to a tester's BRZ, sans springs, for bump/rebound measurements

We need someone local with an S197 that street drives + tracks or autocrosses their Mustang to sign up as a

Vorshlag Tester for this first MCS TT1 set we had built. This would include a discounted install at our shop, a free corner-balance, and hands-on set-up help at a local autocross or track event(s). Go to the recently updated

Vorshlag Tester Page,

read the Tester Expectations, and if it sounds like a fit, sign up to be a tester via the method shown on that page. Don't call, or shoot me a PM, or send a fax, or wire us a telegram, but instead

follow the instructions on that page to sign up.

If your criteria line up with ours, we can get the MCS TT1 installation pictures for the S197 chassis. This would be another great monotube offering we can provide for this chassis (to go along with the offerings we have from Bilstein, Moton and AST). The MCS units are a bit unique in that they only have a 2 to 3 week lead time, are modular and can be upgraded to doubles or with remotes, and the have very beefy internals, shafts and housings.

SCCA Autox at Crandall, August 18, 2013 - STX vs STU?

So we decided to enter this autocross after we installed the MCS TT1 coilovers on

Matt's 2013 Subaru BRZ. This car has been waiting on proper coilovers for almost a year, and after a few fits and starts we finally got a high end, adjustable monotube coilover on the car that was made to the specs we wanted. Working with MCS has been easy and we've installed and sold a good number of their singles (TT1), internal doubles (TT2) and doubles with remotes (RR2) onto our various customer cars.

You can read more about the BRZ project

here, but the plan quickly became to drive this car in its Street Touring class (STX) at the same event as two S197s we brought and ran in STU. Amy drove our 2013 GT (which is

still for sale -

hello, is this thing on??) and Mark C drove again his 2012 GT in STU class, so we could compare times against each other and against the other STU and STX cars in attendance. There were a number of strong regular competitors in STX cars at this event who ran in other classes for various reasons (mostly time of day choices). Still, it was worth comparing to the top ST cars there, so we will, at the bottom of this post section.

Vorshlag Photo & Video Gallery: http://vorshlag.smugmug.com/Racing-Events/SCCA-Crandall-081813/

So Amy Fair, my wife, is a

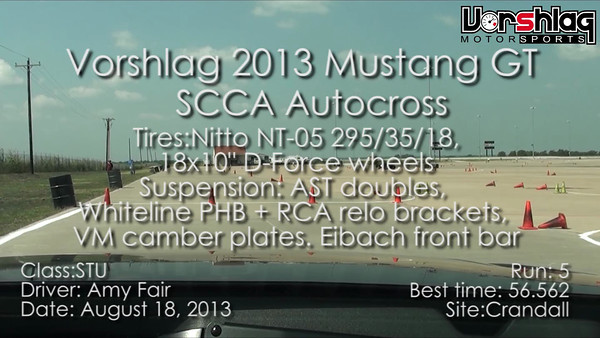

3 time National Champion autocrosser (STU-L twice and ESP-L last year) was running our 2013 Mustang GT in STU. This car is far from under-prepped, and in fact had a couple of "illegal for STU" mods, but this was a good venue to test those things because they were both items we've been asking the STAC/SEB to include for solid axle STU cars. The main suspension items were a $5000 set of AST remote reservoir double adjustable shocks with 400F/200R coilover spring rates.

The 2013 also has a big adjustable Eibach front swaybar, plenty of front camber (VM plates), upgraded and ducted 14" Brembo brakes, and

295/35/18 (10mm wider than allowed in STU - for now) Nitto NT-05s (200 treadwear) on our Vorshlag/D-Force 18x10" wheels. It also has Whiteline rear control arm Relocation brackets (also not yet allowed) plus a Whiteline Adjustable Panhard bar, to center the axle since it is lowered approx. 2 inches. This car had zero power mods, as it already made 377 whp with the bone stock 5.0L Coyote motor - which is too much for 295mm street tires to deal with on TRACK (see above), much less use in thae "knife fight in a phone booth" which is autocross.

Have I mentioned that

this car is for sale? Oh, there, I did it again. Somebody is going to come by and drive this car, realize what an amazing deal this is, and buy it. And then rub it in other peoples' faces.

Mark C is a bit newer to autocross (couple of years) but has a solidly prepped car as well, and was running on fresh RS-3 Hankooks in 285/35/18. These felt like they had a good bit more stick than the year-old 295 Nittos on our car, so the extra 10mm was probably a wash, if that. Mark's Mustang was on AST 4150 coilovers, 550F/250R springs, BMR adjustable panhard bar, the same 18x10" wheels with the aforementioned "200" treadwear RS-3s (they used to be 140 treadwear but Hankook asked the Pope to sprinkle holy water on them and

viola! they are now 200). It also has a Torsen T-2R aftermarket diff, 14" Brembos, and some other goodies, but also stock power.

SCCA Event Results: http://texasscca.org/2013_solo_results/tr13_6_final.htm#STU

SCCA Event Results: http://texasscca.org/2013_solo_results/tr13_6_final.htm#STU

I guess the BRZ was fairly well prepped for STX, too. I figured beforehand that we

might give the two STU Mustangs a run for the money, and was hoping just to keep within a second of the fast STX guys that I watch in our region, like Brad Maxcy's BMW 328is and Mark Sipe's RX8.

Mark C (STU 150) and Amy (STU 197) ran their 5.0 Mustangs in the first heat of four for the day - which was both good and bad. It was good because the surface temperatures on this concrete lot were lower, as were ambient temps in the morning runs. This meant the tires wouldn't get overheated as quickly - but we still had to spray tires on both cars after runs 2-4. At least the didn't have co-drivers to add to the tire heat. But it was bad because the course surface for first heat wasn't as clean as it gets later. Texas Region SCCA does a phenomenal job in prepping the course, with multiple backpack air blowers and brooms, but nothing replaces car tires scrubbing the surface clean. And the course was a bit tricky. It was long, with a LOT of slaloms and near-offsets, perfect for narrow cars - more of what I call a "Miata-centric" course, which we see a lot since the course designer drives a Miata (love ya JJ!). It also had three increasingly tight 180° turn-arounds that joined long-ish acceleration zones.

This was AWD heaven.

Walking it I could see the two STU Mustangs probably having trouble with corner exit traction compared to the AWD cars in their class, as the exits from each major "slow down element" (the three turn-arounds) were pinched off (aka: decreasing) and not what these cars need to "excel". The tightness of the 180s were also going to be tough to navigate in these big cars, as were the slaloms. But the BRZ on 17x9" wheels and brand new 255/40/18 BFG Rivals was almost as wide, at a measured 71" outer track width. So it might struggle through the slaloms, too.

It turned out to NOT be the case for the BRZ. This car was

eating up the slaloms! In the video linked above (which has horrible audio, thanks to a previous gen GoPro HD camera) is my best run in the BRZ. It was a GRIP BUGGY, and at 2700 pounds with 255 Rivals, excellent shocks and great camber, I guess it should be. My first run in the BRZ absolutely obliterated both STU Mustangs. Now I did run in heat 4, so the course surface was cleaner. But it was also 90°F, so it was hotter when a ran, too. And I was co-driving in a 2-driver car with Matt, and we had to do fast driver changes - we barely had time to spray the tires, switch numbers and reset the seat/wheel between runs, and we had help (thanks, Olof and Mark).

So it looked like Matt's BRZ was pretty quick for having zero testing, at its first ever autocross. We basically threw a bunch of parts at this car, took some guesses at set-up, and went out there and drove it. Of course the parts didn't suck... custom spec'd MCS TT1 coilovers, 450#/in springs, Vorshlag plates, Whiteline bars, Enkei 17x9" RPF-1 wheels (15.8 pounds) and brand new 255/40/17 BFG Rivals. It needs a test day to get the bars, spring rates and other adjustments sorted, but we tweaked shock settings and tire pressures during the event and it felt pretty damned good.

This car was hooked UP on this course. At 2700 pounds the BRZ has a huge weight advantage on the 3600 pound S197s in STU, but with 166 whp it lacks a bit in the "go" department. I beat on that car like a rented mule, launching from the Start at 5500 rpms and taking it to redline several times on course; even using 3rd gear on most of my runs. These cars have relatively low power levels, but it just didn't matter. This is autocross, where WEIGHT WINS. In the end the BRZ was 3.6 seconds faster than Mark or Amy in STU and 1.5 sec faster than the winner in STU. That was shocking, and more than a little depressing. I mean, sure, I knew the BRZ could be faster but not THAT much faster than two well prepped STU S197 5.0 cars.

Matt, the car's owner and a 5 year veteran here at Vorshlag, is still a novice autocrosser yet beat the 30 car Novice class handily in the same BRZ. So I guess we had the car set-up well enough from the start. Co-driving the car with him in the last heat of the day made it tight on driver switchover timing, and the car slowed down on my last 2 runs - we

think from both tire and brake pad heat (he had on the OEM pads and I was turning them to goo with my hectic Left Foot Braking). We just could not get the tires cooled down on our last 2 runs.

Left: Twin turbo LSx powered 68 Camaro on street tires! Right: 2 liters of naturally aspirated fury pumping out 166 whp. Its no Coyote 5.0.

PAX Results: http://texasscca.org/2013_solo_results/tr13_6_pax.htm

Left: Twin turbo LSx powered 68 Camaro on street tires! Right: 2 liters of naturally aspirated fury pumping out 166 whp. Its no Coyote 5.0.

PAX Results: http://texasscca.org/2013_solo_results/tr13_6_pax.htm

I will be the first to admit that I'm no "momentum" car driver, yet the times still PAX'd 13th out of 121, and won STX class by a 2.5 sec margin. My best run in the BRZ was run #3, still with with a passenger on board (took passengers on runs 1-3, then took runs 4-5 solo), so I know the car had more left in it. I feel that the tires were just a tick too hot, and word is the Rivals do not take extreme heat well - but what does well in Texas summer heat with 2-drivers running back to back? Not a whole lot. Normally you don't want to have a 2-driver car in any class in this kind of heat.

Amy driving the 2013 (at left) in the same 180° corner as Mark in his 2012 (at right).

Amy driving the 2013 (at left) in the same 180° corner as Mark in his 2012 (at right).

Looking at the results, the two STU Mustangs were bringing up the tail end of their class. It seems that the Mustangs were very close to each other, and in the end Mark beat Amy by .009 sec, which is no small feat. Sure, Amy was coning runs left and right (3 of 5 runs) but her fastest run was clean and on her 5th and final attempt. Maybe her car's tires were past their due date (NT-05s were never that grippy), but she was hustling around that course and stepping on cone bases, cutting good lines. She's been racing since 1993 and often matches or beats my times, but she's a bit rusty in Solo this year. And in case you are wondering, I might guess that.... I

might have put a second on her that day in that car, maybe. I almost never beat her by more than that, and we are often in the same tenth (or she beats me) when we co-drive together.

The image above (click or any other it for larger version, as always) is a "composite results" listing I put together of all of the STX & STU cars. I even dragged in some StreetMod and X class entries, that were really STX or ESP cars (but not the entire X or SM classes). Sometimes the online results disappear over time, so I like to make my own copy. This grouping shows all of the cars that matter to the STU Mustang. As you can see there was a good variety of cars in the STU class, including a 2.5L WRX, an EVO X, an E46 M3 (Gaith's car, which we have worked on several times), and the two Mustangs bringing up the rear. STU should be faster than STX, of course, but it doesn't always work out this way.

continued below