eighty6gt

forum member

- Joined

- May 9, 2011

- Posts

- 4,299

- Reaction score

- 405

Yeah, walbro 405/Ti Automotive F90000262. It will work, I know that. I'm 3d printing a nice new vinyl/nylon (whichever is fuel resistant) lower plastic holder for it so that I can get that fuel filter sock positioned properly with the 3 rubber feet in there. Also using stainless wire to fasten the feet to the plastic holder.

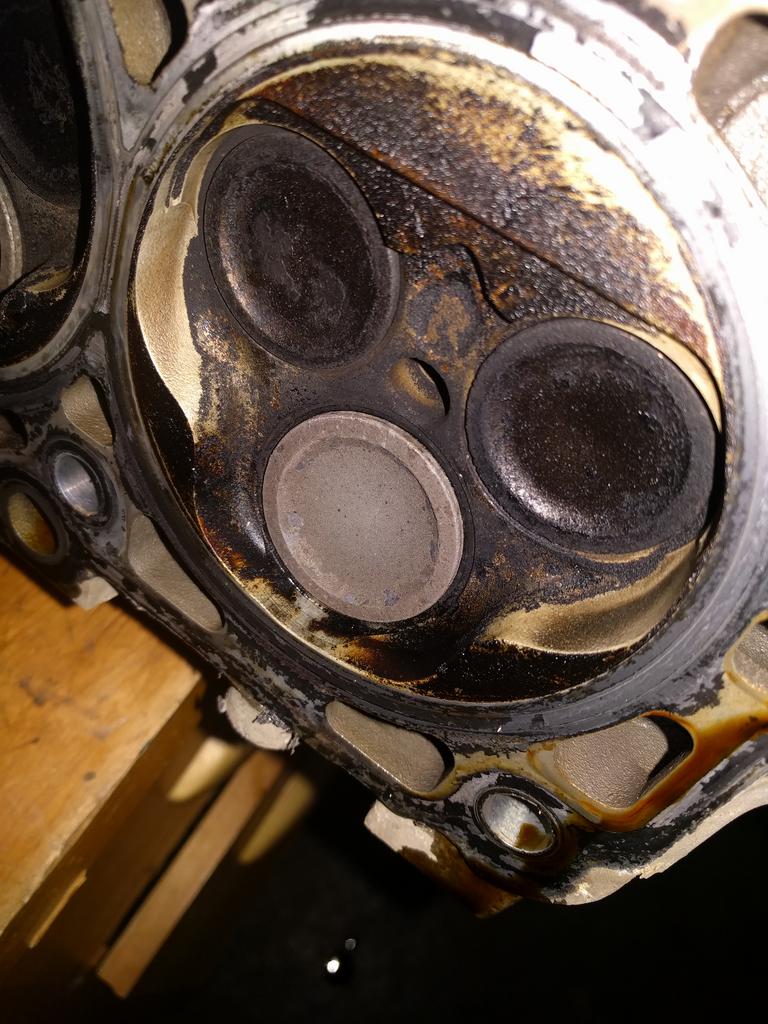

Since my car is a 2008 I'm going to take a risk and think that the lash adjusters and roller followers are as good or better than new ones that I would buy. Known good vs. suspected bad.

Hopefully with careful assembly and stock valve stem heights I won't get the sweet problems others have where the followers jump out into the valve cover to get eaten by the cam and valves, or knock the keepers loose and drop the valve into the cylinder.

Since my car is a 2008 I'm going to take a risk and think that the lash adjusters and roller followers are as good or better than new ones that I would buy. Known good vs. suspected bad.

Hopefully with careful assembly and stock valve stem heights I won't get the sweet problems others have where the followers jump out into the valve cover to get eaten by the cam and valves, or knock the keepers loose and drop the valve into the cylinder.

Last edited: