Mattr89

Cars>Woman

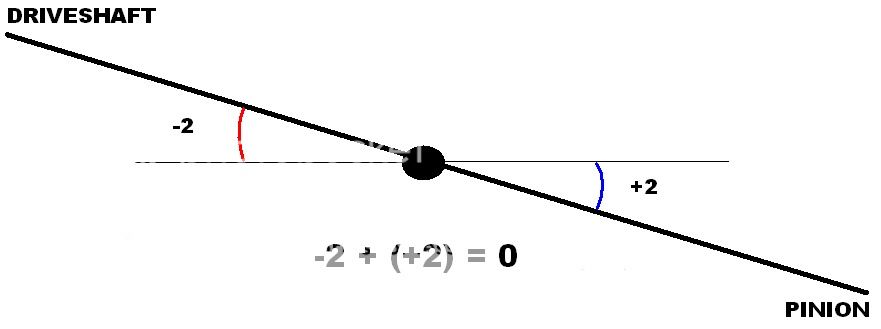

The proper way to achieve your pinion angle setting is to add the angles.

Here is why: (I will make this extremely easy, or try....)

If you have a 0 degree relation, and your drive shaft angle is -2.....then your pinion angle would need to be +2, correct?

If yours isn't -2.....then let's say it is -4. In order to achieve a 0 degree angle, you would need +4 on the pinion flange.

This means, if the drive shaft angle is down -4, the pinion has to be "up" +4 to achieve a "straight line." Correct?

NOW, being that we know how that works....let's do some math.

-2 + (+2) = 0

-4 + (+4) = 0

If you subtract:

-2 - (+2) = -4

-4 - (+4) = -8

If this is hard to understand, see image:

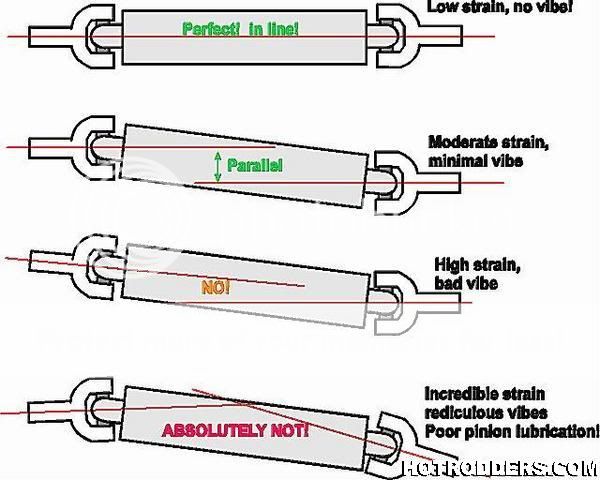

Now, the goal is to ensure there is roughly a 0 degree relation, when under load. That does not necessarily mean everything has to be aligned straight....it means the ANGLES have to be on the same PLANE, and similar. (Parallel)

See below:

The absolute easiest way to achieve the proper pinion angle setting is to use an electronic/digital angle finder that has the feature to "ZERO" it out.

Place angle finder on driveshaft, zero it out, place angle on pinion....and adjust it to your negative setting. Now of course, you will need to re-check both angles before coming to your final pinion angle.

I hope some of you find this useful.

Mine were both in the negative as I took the reading from the passenger side on ramps. With the rear end up high they won't be accurate, the only thing of concern is the difference.

One pinion flange was -5 an the driveshaft was -3.5.

That means a 1.5 degree difference.

After taking the vehicle of the rear ramps the pinion flange now reads -1.5 and the driveshaft now reads 0.

Giving me a pinion angle of -1.5. Because 1.5 minus 0 is -1.5, also 0 minis -1.5 is -1.5.

Also what do you mean zero out the driveshaft? It can't be adjusted by itselft only with the lca's.