continued from above

During the day our crew was busy working on people's cars and supporting our customers who were in attendance. The tech shed stayed busy all day with brake fluid flushes, brake pads swaps, and other various repairs. Some of these were pre-scheduled jobs, but for the most part they were emergency "my brakes are done!" kind of jobs. Luckily we brought plenty of Motul brake fluid, Centric rotors and Carbotech brake pads this time.

This was the largest event that Five Star has ever sponsored at ECR, with over 65 cars. As usual, this event attracts a lot of Mustang owners, but also a smattering of "everything else" and we had a few NASA TT racers our there testing as well. I counted over 25 Vorshlag customers there that day, which is pretty cool - at our first FSF ECR event there were none, but we've been making some headway and have worked on a good chunk of these guys' cars.

We brought our 2011 GT out to the track to show off the new flares, wing uprights and paint, but sadly we couldn't run it on track. Why? The paint was less than 2 days old and too soft to take any grasshopper or tire clag hits. Shiloh would have blown a gasket if I would have brought the car back for paint repairs so soon! Ryan had also just finished the wing uprights the day before - picked the car up from paint Thursday night, wing uprights fabricated and installed Friday then loaded into the trailer for the trip to ECR Saturday, all while finishing construction. I had two Halloween parties that Saturday night (both good ones!), and we started moving the shop the very next morning on Sunday, so it was a busy weekend.

Corey White was super busy, as he had TWO events going on at ECR that weekend. He also helped set-up a "Raptor Rampage" off road event. They had about 15 Raptors show up that took to a 4+ mile off road course that Corey helped create earlier this year. He took us to this site on the same grounds as ECR (its off South of Turn 6) and a few of us got to ride in some very tricked out Raptors. I rode in one with 24" of rear stroke on the dual remote reservoir, triple bypass shocks. The course was wicked and has trees, boulders, and even a big jump. I rode in a few trucks and each one was different, and each one was fun.

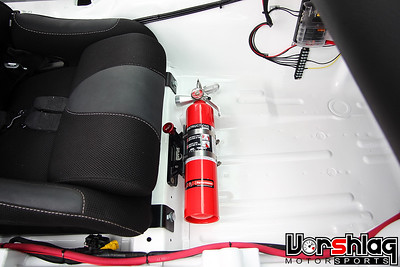

Jamie Beck brought his 2013 GT out to do some initial track testing before the NASA race weekend at ECR on the following weekend. The car worked flawlessly on track but had a weird issue when starting, which we had a work around for that day but got worse when he ran with NASA. The culprit was later traced to a faulty solid state battery disconnect unit, which has since been bypassed then replaced.

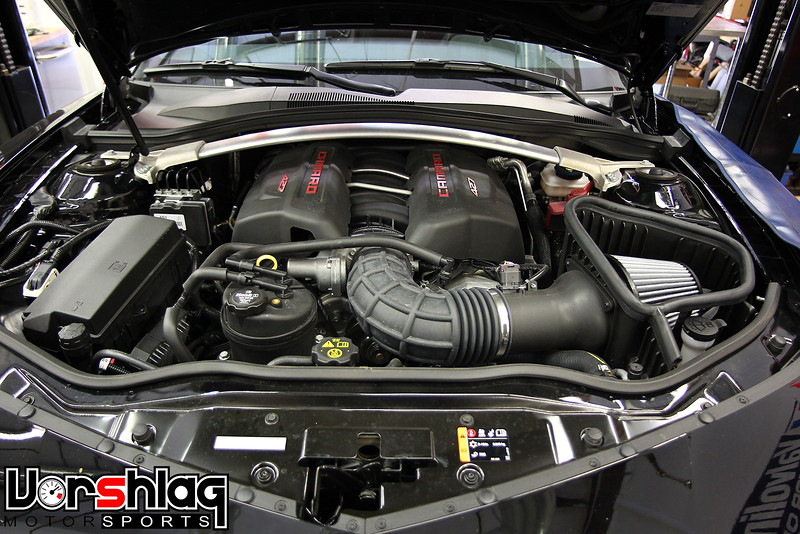

One of our customer's brought his 5.0 Coyote swapped BMW to this event for its first on-track shake-down runs, so we had a plan of attack and sent him out for some short test runs, then into the pits for temp checks and inspections. We had to replace one brake line early on, but after that it went smoothly on track for a couple of sessions. Until the water temps started to spike...

It was weird, because the radiator temps were low on an IR gun, so removed the thermostat, lots of things checked, and eventually realized that the coolant wasn't moving through the radiator fast

enough. Looks like an old junkyard motor's water pump went bad during this event, which was a bit maddening to diagnose... but after other causes were ruled out it was the only one left. It was a part we hadn't installed or touched, but after the pump is replaced it should be ready for more on track action.

Did I mention we did a lot of brake jobs?? ECR is a brake eater and even though we caution everyone to get good fluid and pads before they come here, most folks don't expect it. We worked late into the day, then loaded and and were the last trailer to leave the track that day. Thanks to Tim, Olof, Brad and Amy of Vorshlag for spending their entire Saturday out here helping customers and track folks get through the day (and the next day Sunday moving to the new shop!). Next time we go to ECR will be the annual Toy Run in December, and we are all going to be DRIVING that day instead of wrenching.

It

physically pained me to be at a track I love after parts of it were just repaved with our car we race and NOT to drive it. I had hoped to hop in another car or two that day and at least get some laps, but with a steady stream of cars needing track side repairs I was too busy to break away all day. Lots of folks came by to admire the new front flares. I wish I could have put it out there - but even a simple off track excursion could have damaged the flares, paint or splitter only days before leaving for SEMA. The next weekend at ECR was the last NASA Texas event of the year, and I had to miss that one as well - that's when we were driving to Vegas. Missing this NASA ECR event hurt more than I like to admit, but at least we had nailed down the TT3 regional championship back in June... so missing TWS and ECR didn't hurt

that. Now that we are back from the OUSCI event, I wish we hadn't skipped those two NASA Texas events or NASA Nats East, but hindsight is always 20/20.

Better Personal Safety Gear

Better Personal Safety Gear

I've gotten a some flak from other racers over the past 3 years for my safety gear use. We were running fairly quick times in TTS/TT3 trim for a while without any rollover protection, but after a discussion with our engineer we added the Maximum Motorsports 4-point roll bar. I've always been quick to upgrade to fixed back racing seats and 5+ point racing harnesses (for better control), but roll cages don't belong in street cars, and I resisted that in this car, since we do street drive it a good bit. I have also resisted the optional use of Head and Neck restraint systems, racing suits, and some other gear - but I have been re-thinking that lately.

I tried to use my old 3-layer Simpson racing suit at a few TT competitions this year, but its so heavy and bulky that it quickly made me overheat. This time I spent real money and bought an Alpinestar GP Pro Racing Suit. This SFI 3.2A Level 5 Nomex suit was lighter, made from a newer style fabric that breathes, and it fit me better. I went and tried on 5 different sizes until I realized a European size "58" fits me pretty well. It was painfully expensive, but what's it worth not to be bar-b-qued in a burning car, or worse - sweating so badly that I get heat exhaustion (much more likely)? In August I bought Amy and I both new pairs of

Alpinestars Tech 1-ZX gloves as well, which have the seams run inside-out for better feel on the inside. I used my old gloves at all events (for better feel, both autocross and track) and wore holes in the fingertips, so it was time to upgrade.

The various HANS devices I've tried always greatly limited my ability to turn my head. I have now tested 3 different designs: the HANS brand, the Simpson Hybrid, and then the NecksGen. Each of these required different helmet anchors, so I've got 3 sets of those for my helmet. I used the NecksGen at the SCCA Road Course autocross in September and it actually allowed me to turn my head enough - and as an autocrosser at heart, I am looking out the side windows a lot, aiming for the next corner. The other units restricted my head turning too much, but the NecksGen was tolerable. I borrowed this unit from my friend Ed for use at OUSCI, and I was determined to use it in every on-track session. After the wreck at Road Atlanta in May and the damage to my vertebrae, which

may have been exacerbated by NOT having a HANS device, I wasn't going to track again without it.

Next year, whatever I run seriously will likely have a full roll cage - if its as fast or faster than this TT3 Mustang. I'm getting too old to bounce back quickly from a crash like the one I had in May, and if what we build over the winter is what I hope it to be, it will need a serious cage indeed. I've been pushing my luck on track for far too long - and probably setting a bad example. I cannot count how many W2W guys come by and look at our Mustang after they see the lap times we run and are then HORRIFIED that we don't have a cage in this car. I remind them that Time Trial shouldn't have any car-to-car contact, but the car-to-wall kind scares me enough to want to do the cage, nets, HANS and the rest.

Stickers + 335 Tires + Loading for Trip

The Mustang was almost ready for the OUSCI event after it got back from Heritage for paint, bit there were still a few things left to tidy up. Most of that got done at the old shop but we moved the day after ECR, so some happened at the new place - like the new tire mounting and decals. Olof mounted a brand new set of 335/30/18 BFG Rivals to all four 18x12 wheels. I wanted to race on "sticker" tires so we didn't do any testing on this new set-up with the wider 335 fronts - that was probably a mistake, but I just couldn't afford a second new set of 335 Rivals to test with.

On Thursday October 30th, Kevin Mooney with Mooney Productions stopped by on a tour of 3 shops in and around Dallas that had cars entered in the big OUSCI shootout. He is a camera man and on-air interviewer for their MavTV series and was also going to be shooting video all week at SEMA and of the cars in Optima alley. We had met at previous event and I liked Kevin's attitude about the event and the cars that are featured.

We had cleaned up the entire shop prior to him stopping by, as we were still in the middle of the shop move. He was cool and only shot part of the shop, which we had cleaned up the night before and added this massive decal to one wall of (see above). We had a couple of clean customer cars we had built on hand and one or two of those were in his shots, as well as our 2011 Mustang.

Again, as poorly as we apparently ended up at OUSCI, this footage is unlikely to be shown. Its a shame, as we had a fun interview that everyone here felt went really well. Them's the breaks - gotta place well or be a sponsor to get coverage on the show.

After Kevin left we cleaned up the car, detailed the interior and underhood, and then I fought with Amy about the decal package we would use for SEMA and OUSCI. She wanted to go with the loud WHITE stripes again, and even wanted to get a set of wheels done in white like last year. I reminded her that the white wheels only stayed white for about 2 track sessions, then looked gray forever. Also, the OUSCI series and TV show was supposed to emphasize STREET CARS, and as I was told by one USCA organizer, the stripes made the car "look too much like a race car", so Jason and I convinced her to go with a toned down livery instead, which Jason cut on our vinyl plotter that Thursday.

On Saturday, the last day of moving, we finally added the smaller "Vorshlag" stickers in black to the rear shoulders and small sponsor decals to our manufacturers of the parts we run along the sides, leaving ample room for the OPTIMA door decals and event sponsor stickers on the sides as well as to of the windshield. We didn't get in our request to USCA in time to get the event decals so we had to wait until Monday in Vegas during "load-in" to get them, but we assumed we could show up early and grab them in time for the big Ford 50th Anniversary picture shoot Monday afternoon at 3 pm (but that assumption was wrong). Brad, Jen and Amy hand cut the stripes for the hood and laid them down minutes before the car went into the trailer (they were still wet so we left the transfer paper in place).

I took a quick romp down the parking lot and made some Figure 8 turns to see if the 335s rubbed up front. Nope, all clear. Then we loaded up for the 22+ hour one-way tow to Las Vegas. We brought two mounted spares and one dismounted spare tire for the trailer, as we had too many blow-outs last year going to Utah for NASA Nationals and didn't want to take any chances.

After loading up at the shop we went to our house and loaded our clothes, food and other stuff for the TEN DAY trip. We had hoped to leave by noon but it was closer to 6 pm before we rolled out. Luckily we had an extra day padded into our time budget to get there, so we only lost 6 hours of the extra 24 we had budgeted. Off to Vegas we went, with high hopes! Jason was driving up the long way and planned on being at the show on Tuesday. Olof and Jon were leaving Tuesday in to arrive early on Wednesday, Brad was flying in Friday and even Costas was going to join us Friday through Sunday. We had a big, experienced and capable crew on hand to help me at the event, and also to talk to the various vendors we knew at the SEMA show.

Just wanted to point out that while our shop was shut down for a couple of weeks during the move and SEMA (we turned away a lot of work and cleared the schedule), we're fully operational and have openings on the schedule now. Need some fabrication or race prep work? Suspension install? Have a heavy wallet that is weighting you down?? We can help.

Tune in next time for part 2 of 3 - the SEMA show!