It just seems weird that it's just happening on the one cylinder. I will check into the things you mentioned but this really has me perplexed.

I hear you, but when T\S'ing these more modern FI systems I've found you have to take everything into consideration & not make assumptions then go thru & eliminate everything that is not to find the cause that is.....IOW's test, don't guess. It also helps to learn how all of this actually works, both individually then as a collective to help to decipher some things. You also have to do the same w\ each part of the system as far as design goes to understand if there is a variation present that can set up a situation to affect only 1 cylinder in a more drastic way vs the others.

The following is stuff that I've thought of to consider just from reading your post.................

Since you've ran 3 different spark plugs thru the same cylinder & got the same result that IMHO rules out the spark plugs themselves as an issue.....ID's the cylinder. You've posted how the porcelain looks on #2 cyl but how do the rest look? (I don't know but you do) Are the rest all clean looking except #2? Or do all look kinda similar except #2 is much darker......if this is so then this may indicate a more common issue that is affecting #2 cyl the most but does affect the rest as well........

The issue w\ #2 cyl is heat related (heat transfers thru porcelain thru shell to cyl head).....more heat is being transferred thru #2 plug to cyl head vs the rest that is above its design tolerance range (or is not being transferred from shell to head vs the rest) to destroy this plug......how can this happen? Are you using anti-seize (is it copper or aluminum....HT aluminum would be better choice since the heads are aluminum to not induce galvanic corrosion between the plug shell & cyl head) on plug shell threads or are dry mounting them to cause heat transfer issues (you did mention it has come loose at times)? Is A\F mix being leaned thru this cyl vs the rest causing excessive detonation thus excessive heat.....now how can this occur on just 1 cyl.....or is this actually happening on all cylinders but just bad enough on #2 cyl to cause the plug to consistently fail here but not w\ the rest? Could this be indicating an air distribution issue within the intercooler to individual cylinders? Where in the system design can unmetered air enter by design? Is the EVAP system hooked up & being used......if so has this system been checked\tested recently\periodically for integrity? How does the SO PCM control this, how does it know when the canister is empty (unmetered air percentage increasing) & getting excessive? What can affect O2 sensor feedback fidelity to cause erratic fueling variations? How was the car being operated most when all this is happening? Mostly normal street driving or mostly at the strip under max loads (this will determine how much\often the PCM is operating EVAP purge cycles during engine operation)?

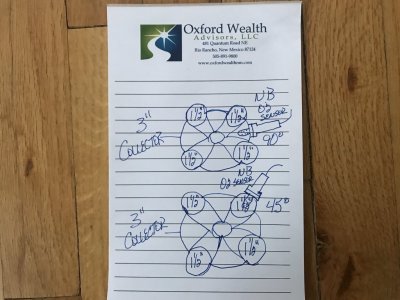

You do have LTH's installed........where in the collector is the O2 sensor mounted & which cylinders are closer to this sensor thru the collector merge to affect\sway the sensor exhaust sample volume\density from each cyl exhaust pulse to determine how the SO PCM will adjust the A\F mix for the next cyl in line on the same bank to fire (SO PCM can read individual cyl exhaust pulse using O2 sensor transport delay & engine timing but SO PCM is not programmed to individually adjust fueling per cyl....only by bank so depending on how the cyl exhaust sampled that is ahead of #2 cyl in the firing order in B1 will determine how much extra fuel thru STFT's (feedback that will be used to make fine corrections to fueling that are initially made from the MAF readings\calculations derived from ALL cylinders) #2 cyl will actually get (or how much extra fuel will get taken away) thus any unmetered air entry can skew this even further. LTFT's are an avg of all the STFT feedback readings\adjustments over time from individual cyls (that vary from the MAF calc's based on all 8 engine cyls drawing air thru the MAF sensor) in the bank that the O2 sensor serves so can correct for most of this but NOT ALL of it (the rest the PCM extrapolates or assumes if you prefer). You're running a FFE but you still use the rear O2 sensors.......can you determine by looking at the operational O2 sensor voltages of both B1S1\B1S2 to see if something jumps out to consider looking at B1S1's operation to ensure B1's O2 sensor feedback fidelity?

NB O2 sensors do not have a nerst cell (essentially an electronic air pump to ensure a consistent exhaust sample density from all cyls in a bank is contacting the sensor's element) like WB's do (1 of the main variables that make WB's so accurate vs NB's) thus NB's are affected by placement in the collector\pipe, the depth of the bung it's mounted in (determines how much of the shielding\element is exposed to internal exhaust flow) & the size (ID) of the pipe (determines how much exhaust flow velocity\density % at the pipe's inner surface area adjacent to sensor shielding.....not in the center of pipe......is entering the shielding to make contact w\ the element) so a lot of these seemingly small items can actually add up to this actually happening in tandem to cause this issue in a specific cyl......but how are you gonna know this?

You have indicated getting a borescope to check internal for any sign of physical damage to validate detonation as a cause of issue in #2 cyl.....also be good to look in the rest of the cyls to also look for indications of same to validate if symptom is widespread as well but especially in Bank 1 where potential fuel control issue is appearing due to plug inspection. Could follow up w\ a compression test\leakdown test to confirm\deny other symptoms as well as doing an injector pulse rate test on all injectors to see if #2 cyl injector is off compared to the rest......the more info gathered to eliminate what is not will get you to what is & get you there more accurately the 1st time....

Unless you test for all this to ensure that all is in spec & operating properly you're only assuming that all else is good. This is why it can be so perplexing to figure out..........you see the result of something going on but you can't readily (read quickly or easily here) figure out the cause........

This is a sample of how I use process analysis to tackle an issue such as this.....then run thru all of it testing\checking to eliminate all that is not to then find what it actually is.......but this is how I do it.

YMMV..............

Most in here would see all this as nitpicking or unnecessary......but then ask why would you? If you don't have a good enough handle of all the particular variables in\of your particular configuration & how well you understand the operations of each system separately then also as a collective, you can be open to misinterpretation of symptoms occurring before you & miss something in your diagnosis that can point you to the cause.......if you get into the habit of waiting on the PCM to flag a DTC to alert you of a situation & what to look at to point to a cause you can be too late to save your engine from catastrophic damage.

I posted due to me experiencing the exact same issue w\ a plug in my 4.6L as you describe (my case was 2 plugs.....in same bank & next to each other.......which were the farthest 2 cyls away from the offset EVAP port in the FPIM but this EVAP port also pointed directly into #1 & #2 cyl intake runners in the same bank & Bank 1 plugs were far away the worst affected from overheat due to detonation but all plugs showed symptoms of same but only #3 & #4 plugs showed blow thru into plug wells thus were leaned out far worse than the rest & I had actual Forscan datalog recordings of actual erratic STFT's\LTFT's along w\ EVAP operation in real time showing evidence of excessive unmetered air entry occurring thru EVAP system due to erratic O2 sensor feedback signal--STFT's--that caused the PCM to excessively purge EVAP--PCM uses STFT's rise above normal switching pattern to determine if EVAP canister is empty--to create the excess unmetered air entry due to PCM being unable to determine if canister was empty until it forced the STFT pattern out of "normal" enough to decipher the results by opening the CPV further making the situation worse).....then noticed the EVAP port route design on an OEM IM vs the FPIM to tie it all together (if I didn't know\understand how this all worked both individually & as a collective there's no way I could've picked all this out of a couple of datalogs). Then later on, based on all these earlier findings I got a hunch to test the 2 front O2 sensors voltage operation\heaters on a cold start from OL to CL transition & found that the O2 sensors I was using at the time (Ford F85F-9G444-BD.....made by BOSCH) were very poor in operation (didn't respond initially when heaters were hot enough for PCM to switch from OL to CL so PCM was flooding engine w\ fuel thinking it was lean until the sensors finally responded going rich then PCM pulled all excess fuel back to normal....which also had a hand in the plug damage found) but none of this threw a DTC--not even a pending DTC--as the sensors responded before the timer counted off (but I followed process & tested them anyway.......I had earlier swapped these in replacing my good NTK 22060, 22500 O2 sensors when running the cat CE ratio checks testing the Kooks Hi Flow race cats.....didn't see any change at the time so left them in.....so this 1 was on me) thus eliminated a future issue in the process as I also knew this had to be occurring whenever the engine went into DFSO as well (engine pumping air thru exhaust cooling the O2 senser elements already knowing the sensor heaters aren't that strong) thus causing this issue to happen temporarily once the PCM turned the injectors back on to return engine to operation....also affecting the plugs condition. The badly burned plugs were a symptom......the bad O2 sensors found AND the poor EVAP port routing design discovered in the FPIM creating erratic EVAP air distribution thru IM was the cause.....EVAP system itself was fine w\ all components tested\operating fine. All driving was normal engine operations where the PCM will perform EVAP operations (PCM disables EVAP during WOT) so I knew my issue wasn't due to high engine load% calc's but my tune's load% mapping has VCT limited to 20* max retard so avg engine dynamic cyl pressures will be higher to maintain better low speed TQ output thus the potential for detonation at low engine RPM's if something else was off\out of whack (this I also already knew beforehand so was factored into analysis) & thru all this I also discovered after the fact that this EVAP port issue in the FPIM was responsible for my Kooks Hi Flow cats to fail OBDII IM Readiness (had tested all this 1 yr earlier & knew that both cats initially passed but over time slowly failed but only B2 cat just barely failed w\ B1 cat passing both times indicating that something was off here--if cats are bad they should both set a pending DTC on 1st check after a KAM reset then set a permanent DTC on 2nd check.....std SO PCM operation for cat CE checks after a KAM reset straight out of FoMoCo's OBDII Theory & Operation Summary for 2009 vehicles......never happened during 2 successive tests......was using the same NTK 22060, 22500 O2 sensors I'm using now which tested good & were new then thus eliminated the O2 sensors back then as the plugs were brand new thus eliminated them as the EVAP system was also replaced & tested good back then which only left the FPIM's EVAP port routing design causing PCM to cause excessive EVAP purging from erratic STFT's which threw off cat CE calc's by flooding cats w\ excess unburned air--PCM uses STFT's in assessing exhaust O2 % going into cats to ensure proper CO & HC oxidation--that they couldn't use up thus got thru the substrate & hit the rear O2 sensors to slowly increase their switch counts relative to the front O2 sensors over time.....not because the cats were bad.....but I couldn't figure it out back then as I didn't have no other data to go off of at the time......the laptop & Forscan software came later on that fall) as I noted the cat CE ratios started improving immediately on each part replacement I made this spring (swapped out the IM's 1st, then swapped out the O2 sensors 2nd, then swapped out the plugs last w\ a set of used plugs--not new ones) thus validated the cause of that issue after the fact. So my new high dollar oversized MF #5461336 CARB-cert\VEI matching cats now get the benefit of all this testing\rectifying of these issues to further enhance their already excellent performance on a non-OEM equipped, cammed, FBO , tuned NA 4.6L engine to legally pass current EPA emissions stds if it needs to in the future......as currently configured to boot.

Sorry for all the wall of texts but I typed this to show that I practice what I preach thus is why I can say what I say w\ assurance as I also have the data on hand to back it up.

I know you'll find your culprit that is causing your issue on #2 cyl but you might need to go thru a process of elimination to unmask it.

Hope all this helps.