Here is my build ~ 4.6 to a 5.0 Forged Internals!

Started in November 2011 in our shop

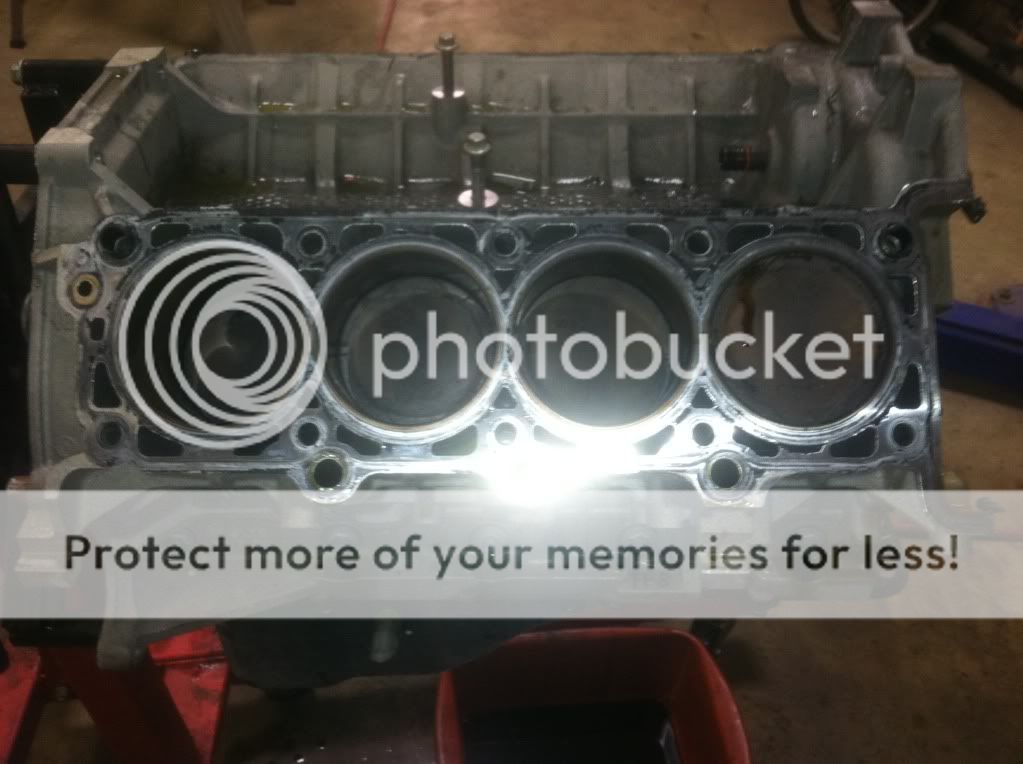

Pre 5.0l build (Stock 4.6 Motor)

Saleen Supercharger 3.4 Pulley

3.73 Ford Racing Gears

Steeda CAI

Panhard Bars

Tokyio D Specs

SLP Line Lock

Flowmaster Axle Back

Kenne Bell Boost-a-pump

39lb injectors

SCT Handheld Tuner

This is a video of the car at the track before the build.

Northside Performance - 2006 Mustang GT - YouTube

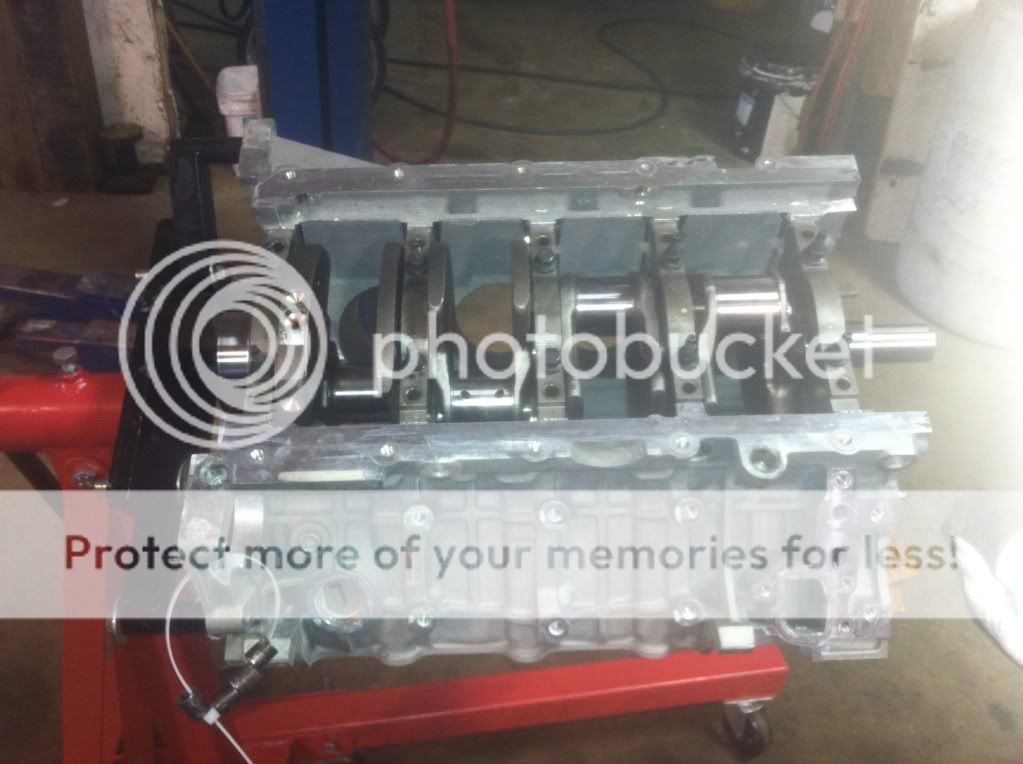

Ok now that we got that outta the way. Here is my build.

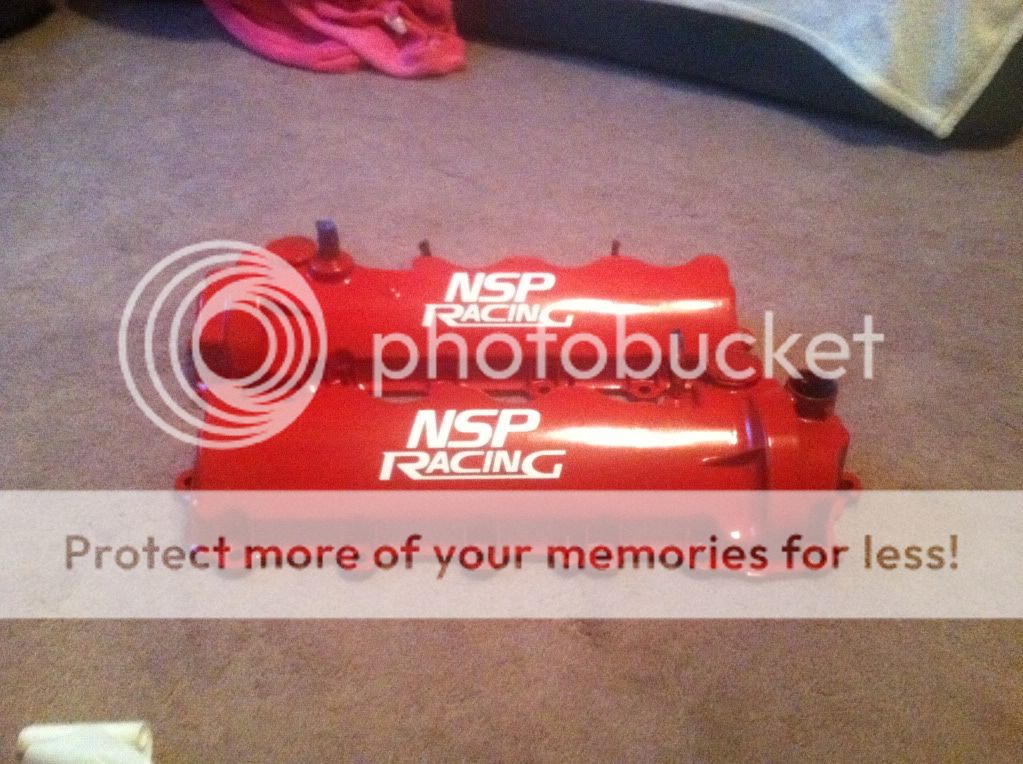

New Parts:

127bren2 Cams

Forged Kellogg Crank

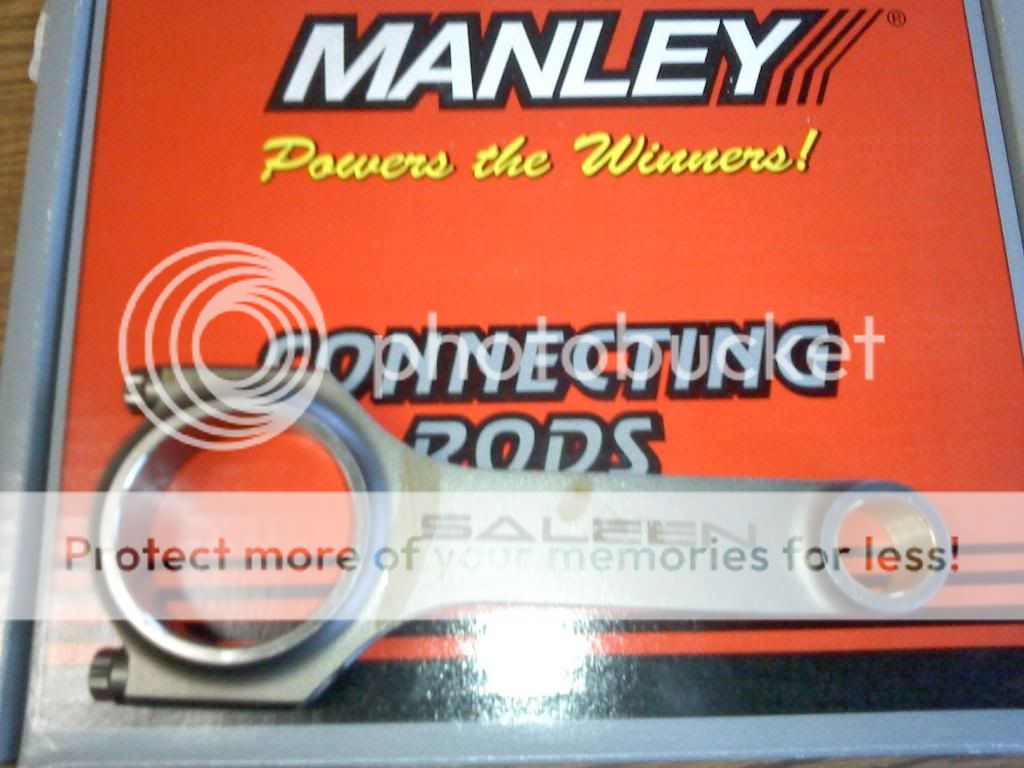

Forged Manley Rods

Forged CP Pistons

Pypes Headers and H pipe

BMR LCA and UCA and 3rd link (adjustable)

3.2 Pulley (40 Bucks )

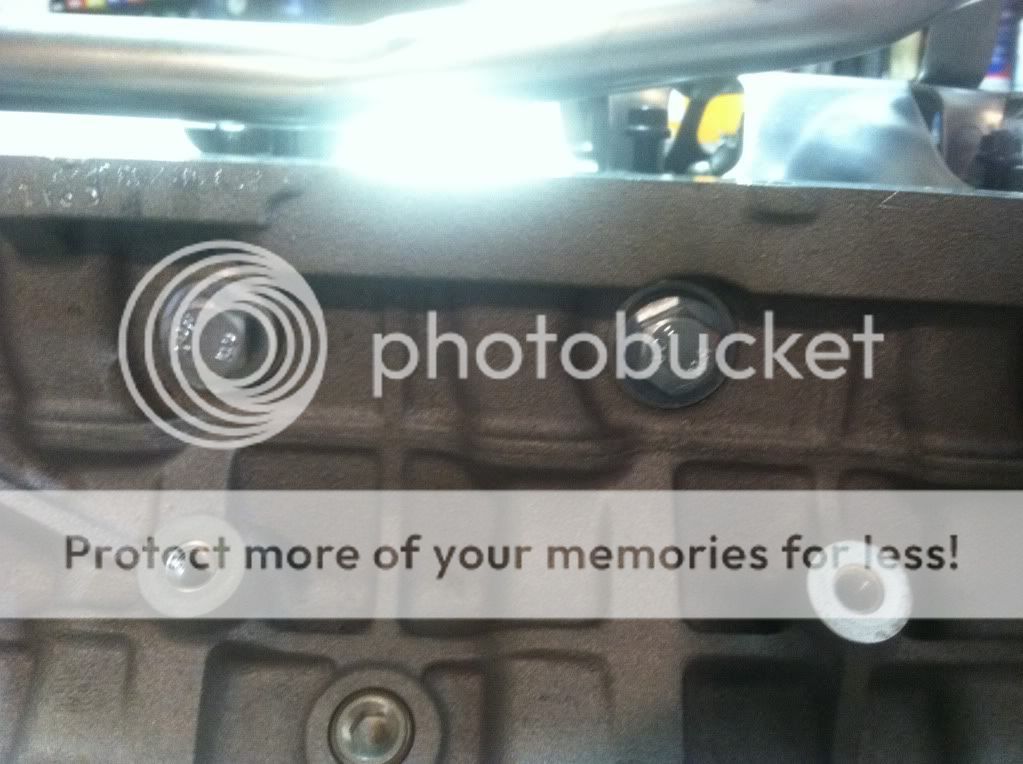

One thing that isnt included in the kit from brenspeed is a 8 bolt flexplate, stock is 6 and the new crank is 8 bolt

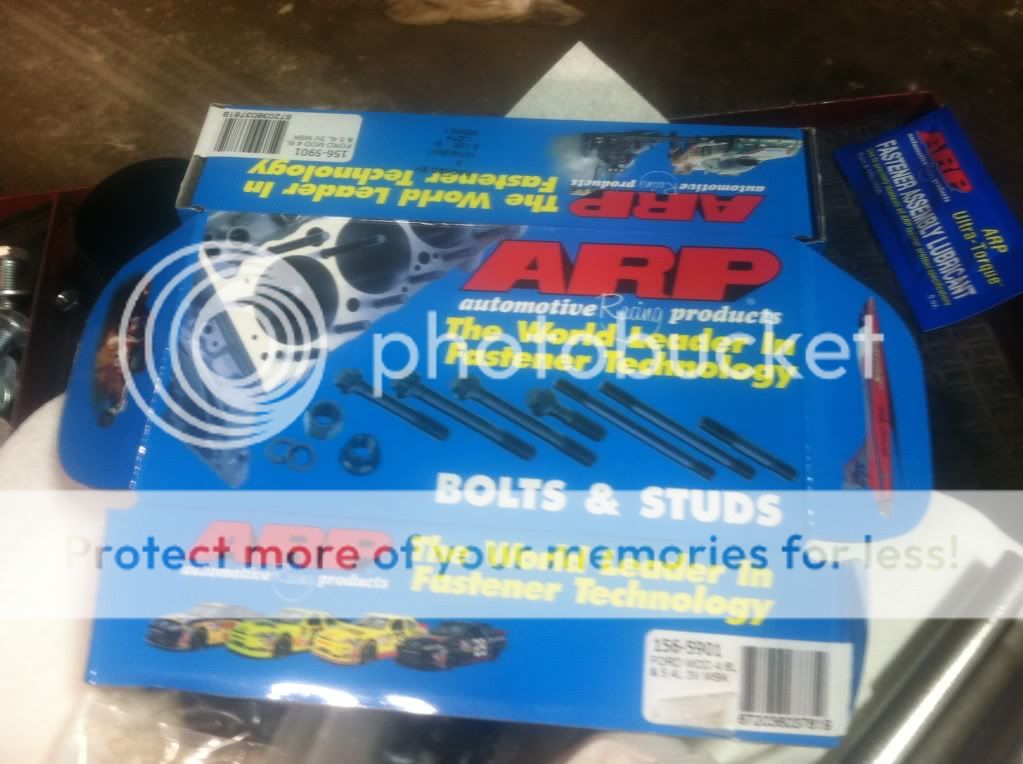

Also head gaskets, head bolts, main bolts, etc, stock head bolts are one time use, but they are strong so you can order them again to save money

Main studs need to be changed, they are spendy but worth it.

The idea was to drop it out the bottom with the K member and Wheels Still attached.

This image has been resized. Click this bar to view the full image.

This image has been resized. Click this bar to view the full image.

Drained all the fluids before disassembly, this took about a hour in its self along with disconnecting all the wires and taking the brake lines out. one of the hardest parts was the AC but we ended up draining that, and taking it out with the starter. Also taking out The AC.

Click this bar to view the full image.

Click this bar to view the full image.

Driveshaft out now since we are taking the transmission with it, only way to get it disconnected from the motor

After double and triple checking everything was disconnected we raised the car to seperate it, very slowly and very carefully.

Click this bar to view the full image.

Click this bar to view the full image.

we then used the cherry picker to seperate the K member from motor and Transmission

This image has been resized. Click this bar to view the full image.

This image has been resized. Click this bar to view the full image.

Once we got the motor off the K-Member we then wiggled the Transmission off.

This image has been resized. Click this bar to view the full image.

This image has been resized. Click this bar to view the full image.

Here is the Empty hole haha

Click this bar to view the full image.

Click this bar to view the full image.

After that we got the Engine on the engine Stand

Click this bar to view the full image.

Click this bar to view the full image.

From there we took off the stock manifold, some very dinky little things

Good ole 5R55 auto

This image has been resized. Click this bar to view the full image.

This image has been resized. Click this bar to view the full image.

We then took off the heavy SOB saleen supercharger.

This image has been resized. Click this bar to view the full image.

This image has been resized. Click this bar to view the full image.

Started in November 2011 in our shop

Pre 5.0l build (Stock 4.6 Motor)

Saleen Supercharger 3.4 Pulley

3.73 Ford Racing Gears

Steeda CAI

Panhard Bars

Tokyio D Specs

SLP Line Lock

Flowmaster Axle Back

Kenne Bell Boost-a-pump

39lb injectors

SCT Handheld Tuner

This is a video of the car at the track before the build.

Northside Performance - 2006 Mustang GT - YouTube

Ok now that we got that outta the way. Here is my build.

New Parts:

127bren2 Cams

Forged Kellogg Crank

Forged Manley Rods

Forged CP Pistons

Pypes Headers and H pipe

BMR LCA and UCA and 3rd link (adjustable)

3.2 Pulley (40 Bucks )

One thing that isnt included in the kit from brenspeed is a 8 bolt flexplate, stock is 6 and the new crank is 8 bolt

Also head gaskets, head bolts, main bolts, etc, stock head bolts are one time use, but they are strong so you can order them again to save money

Main studs need to be changed, they are spendy but worth it.

The idea was to drop it out the bottom with the K member and Wheels Still attached.

Drained all the fluids before disassembly, this took about a hour in its self along with disconnecting all the wires and taking the brake lines out. one of the hardest parts was the AC but we ended up draining that, and taking it out with the starter. Also taking out The AC.

Driveshaft out now since we are taking the transmission with it, only way to get it disconnected from the motor

After double and triple checking everything was disconnected we raised the car to seperate it, very slowly and very carefully.

we then used the cherry picker to seperate the K member from motor and Transmission

Once we got the motor off the K-Member we then wiggled the Transmission off.

Here is the Empty hole haha

After that we got the Engine on the engine Stand

From there we took off the stock manifold, some very dinky little things

Good ole 5R55 auto

We then took off the heavy SOB saleen supercharger.

Last edited: