rad_rob

forum member

- Joined

- Jan 25, 2008

- Posts

- 230

- Reaction score

- 0

So for my full time job, I work as a CNC programmer/machinist. I have been doing it for a while now, and along the way, a lot of projects have come across my desk. The shop that I run is a pretty big shop, and I am lucky enough to be able to use it whenever I need to. So on top of my full time job, I also take on my own side work making custom one-off prototype parts for people, or even just parts for myself. I have always wanted to get into machining a custom set of wheels, and a couple of weeks ago, I had the oppurtunity brought to me.

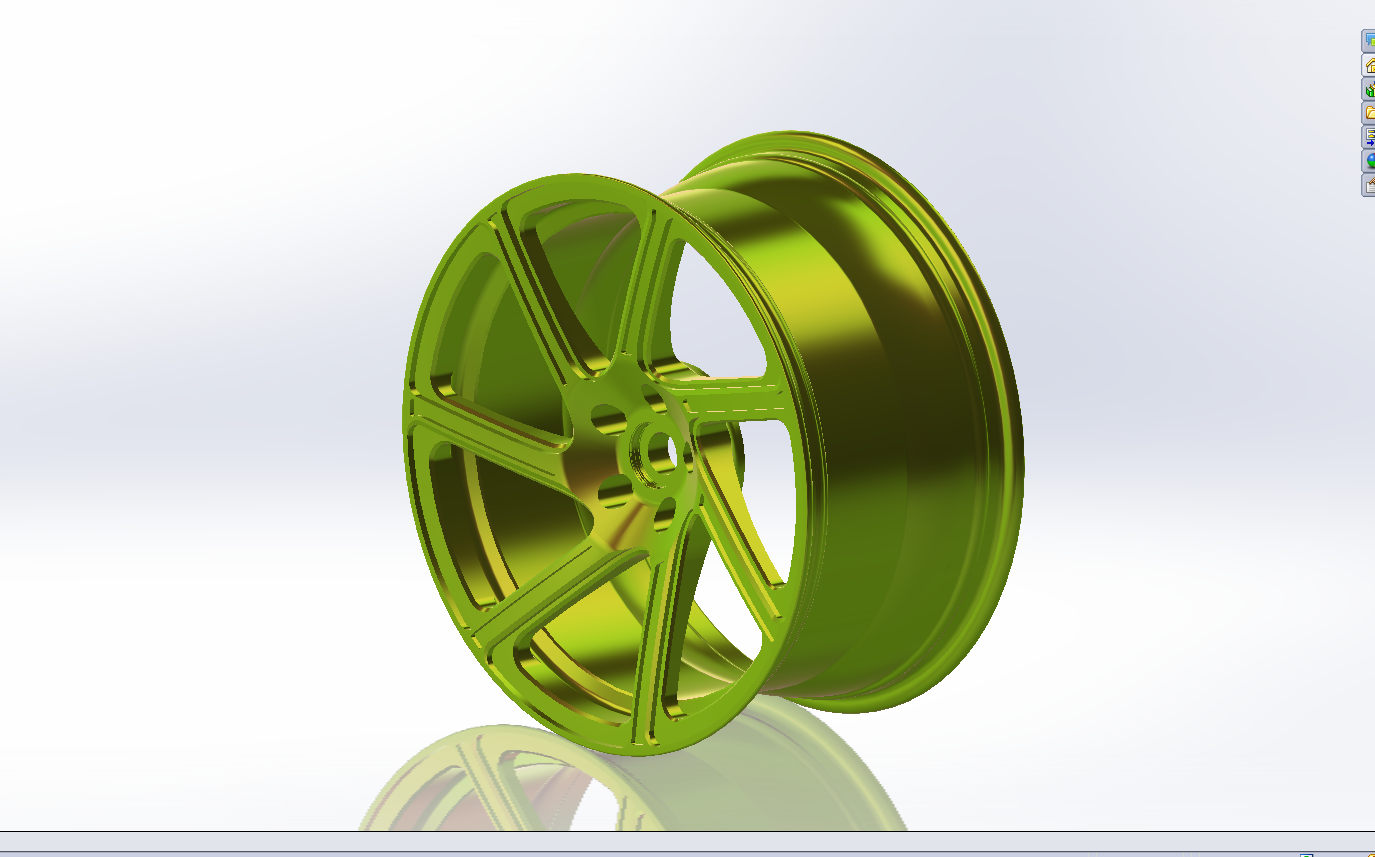

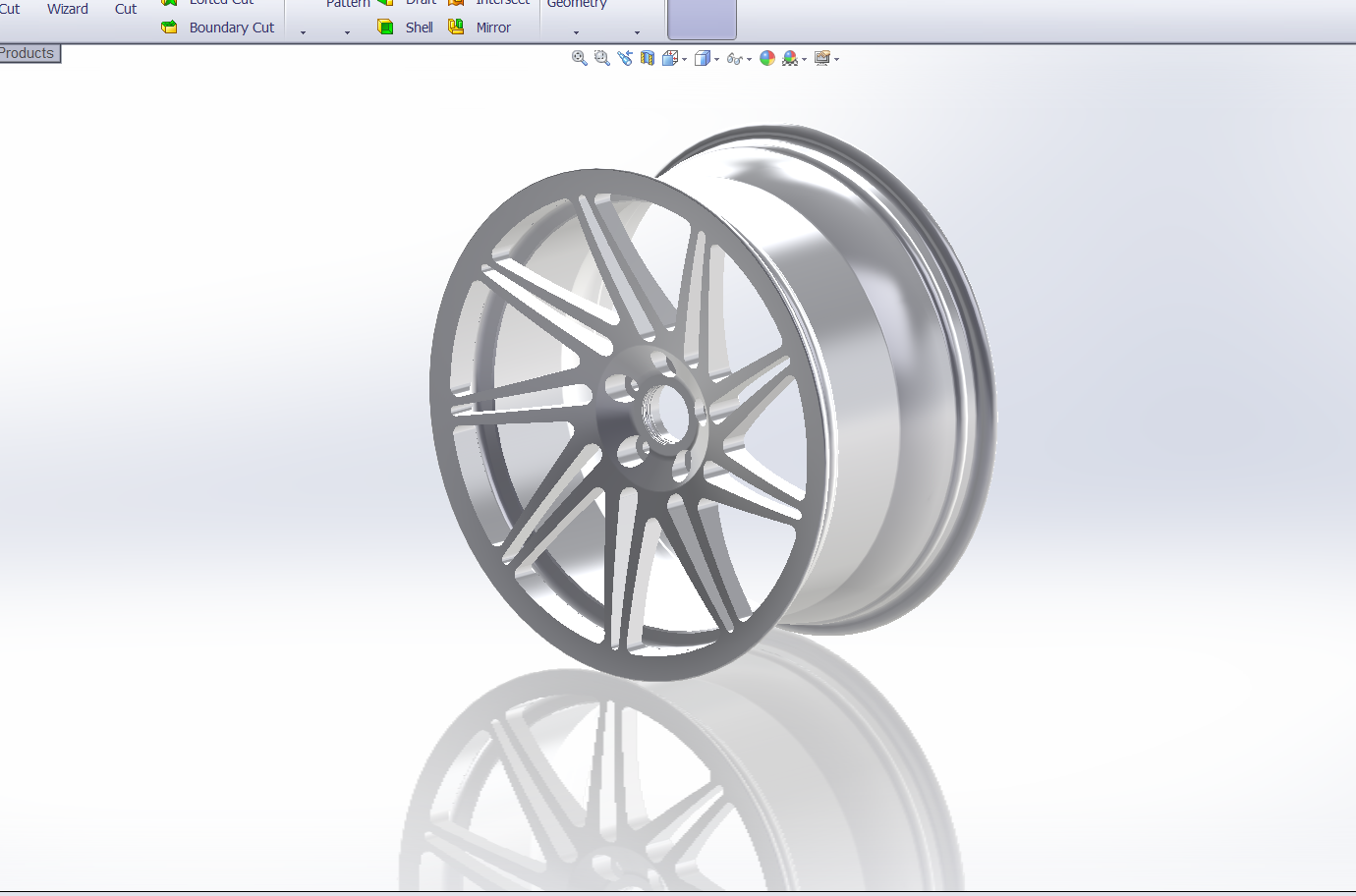

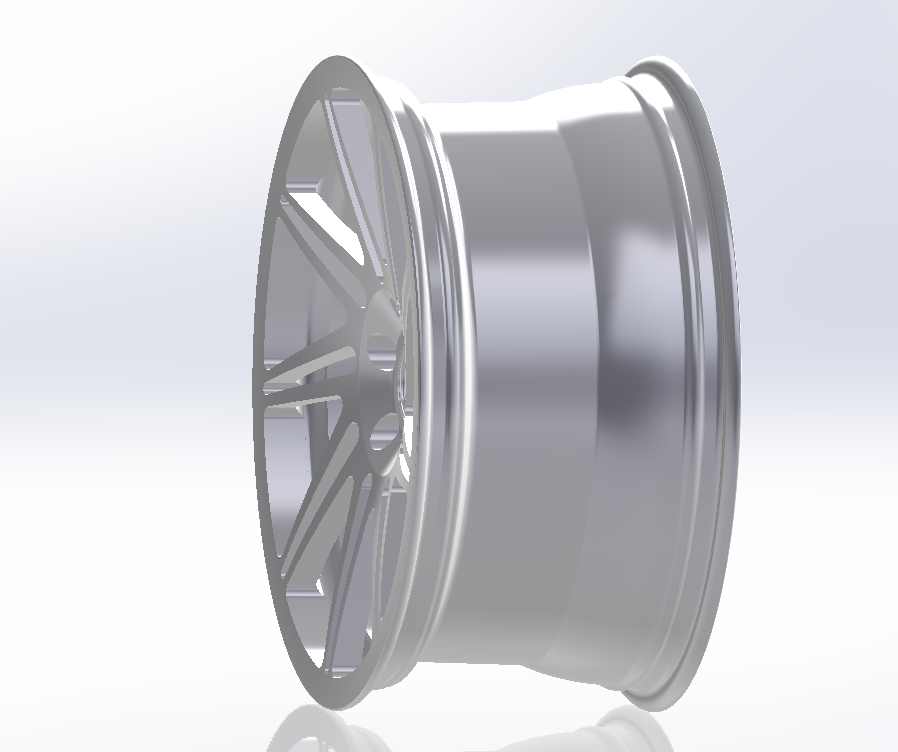

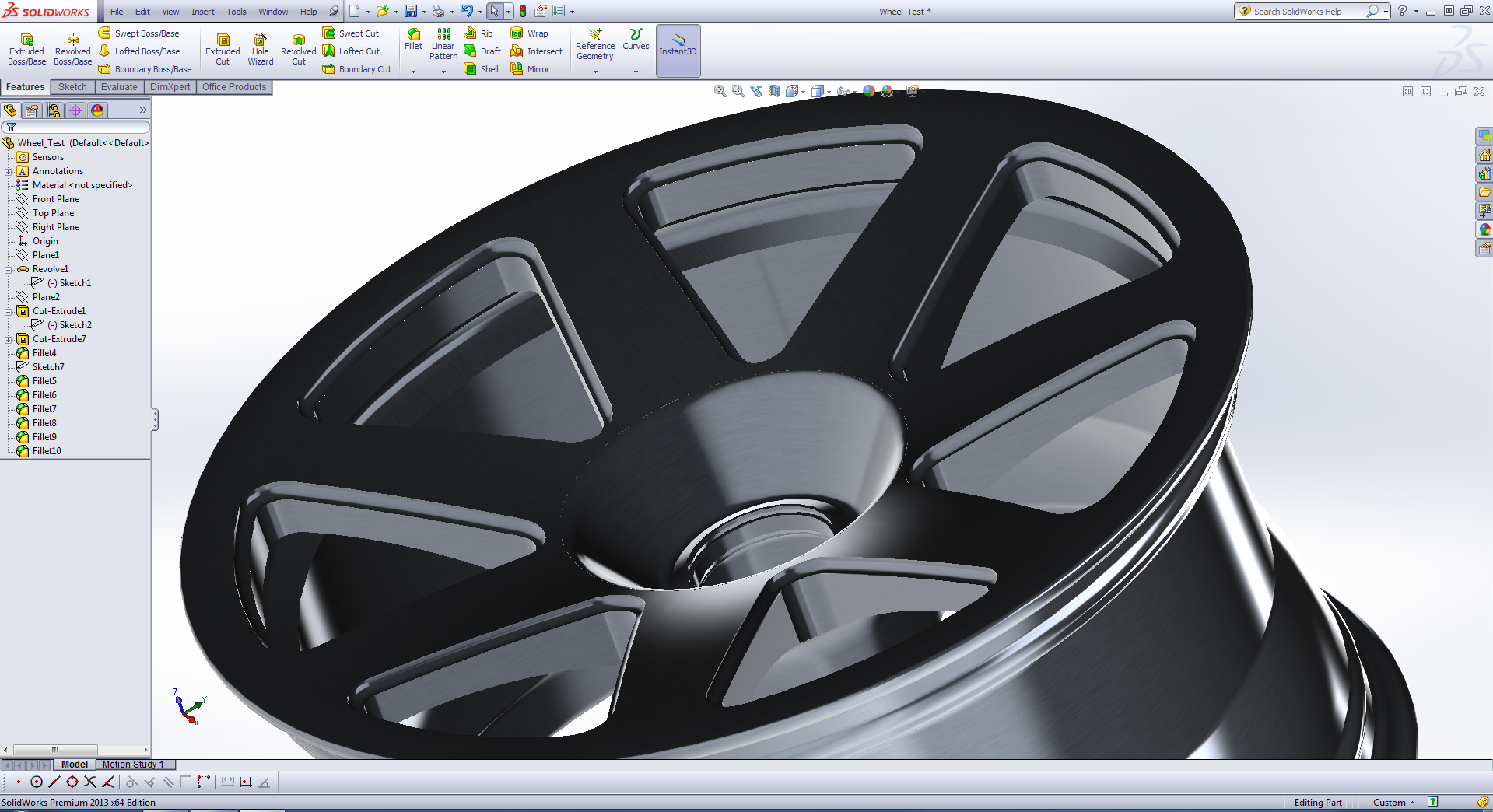

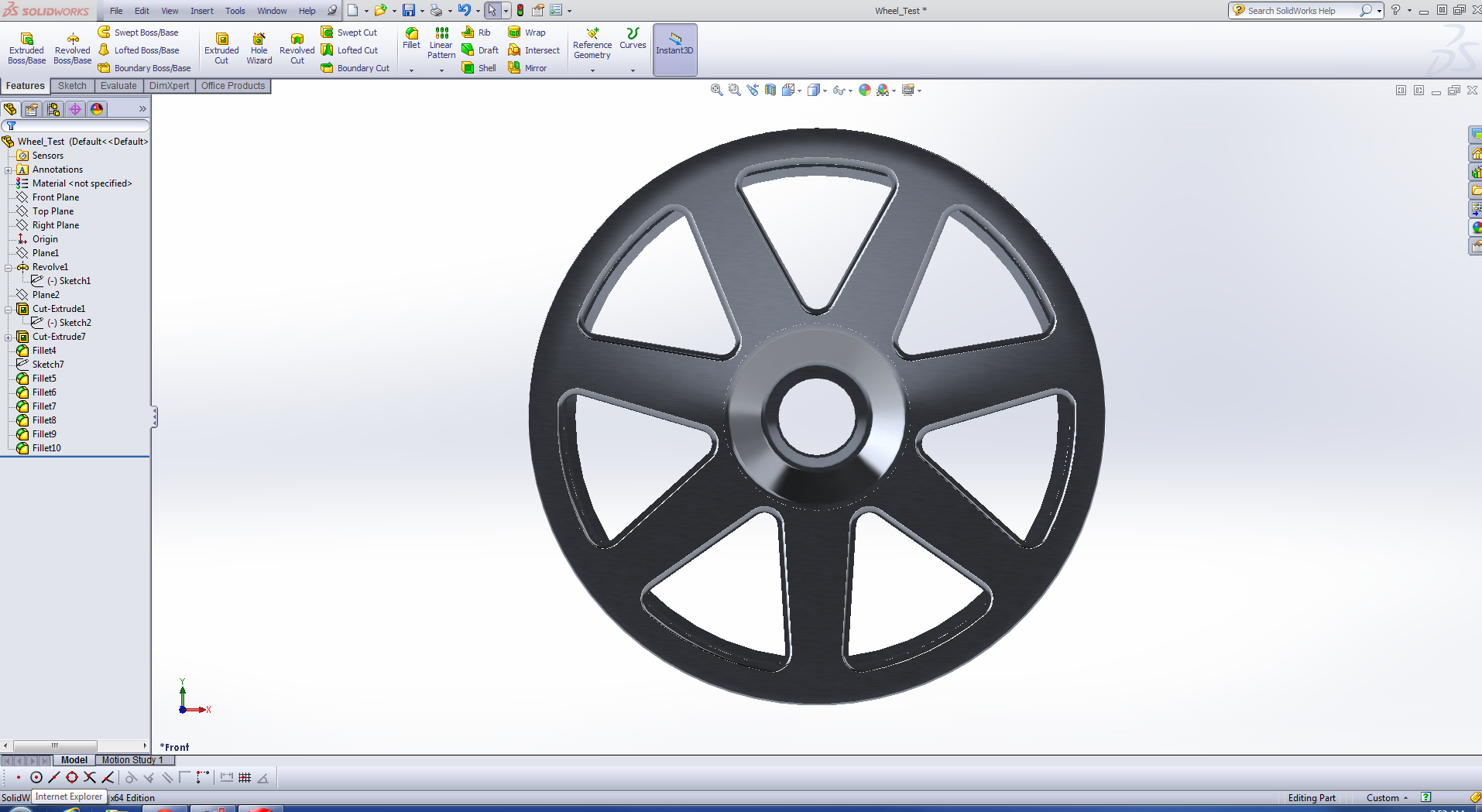

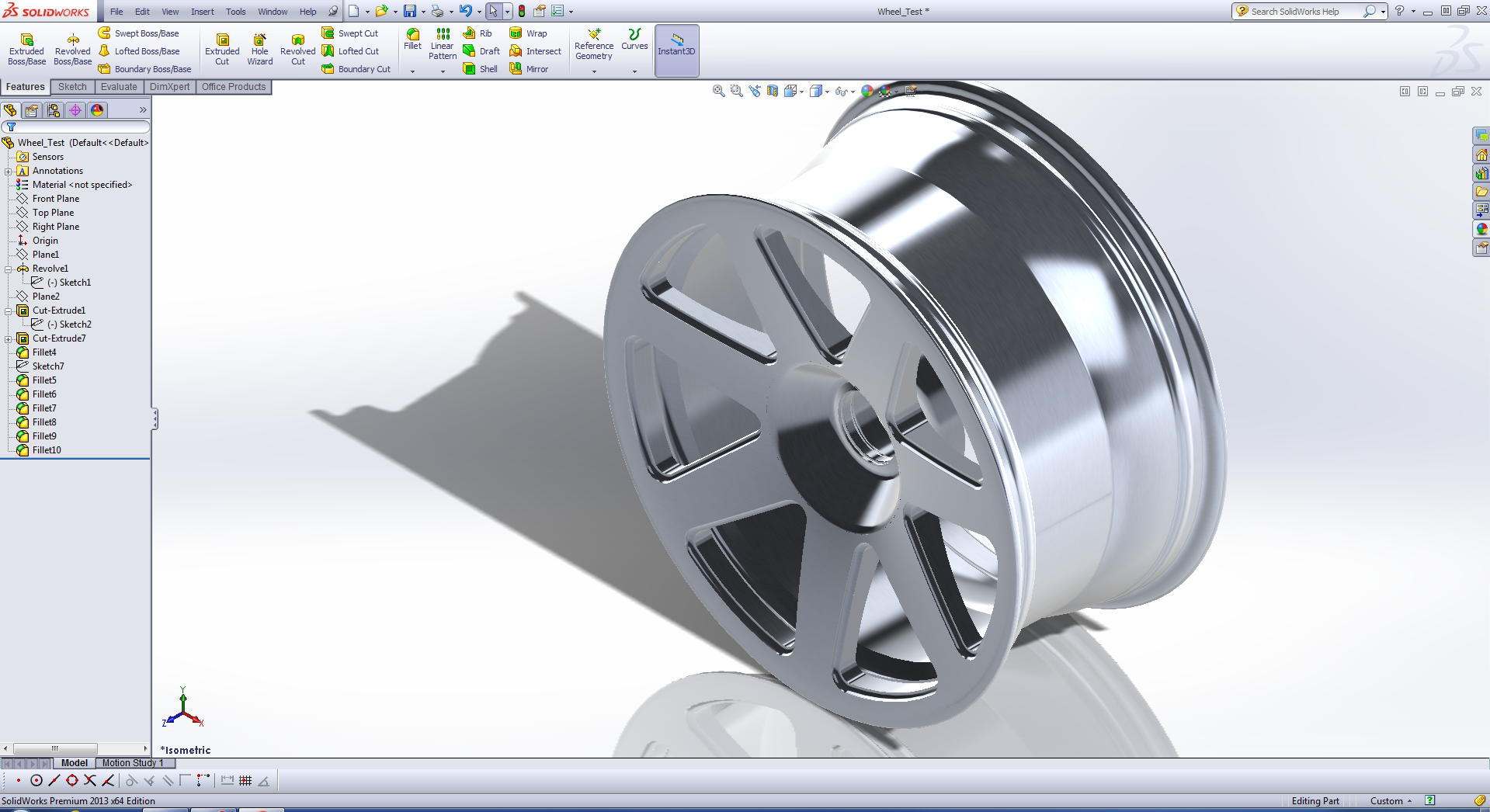

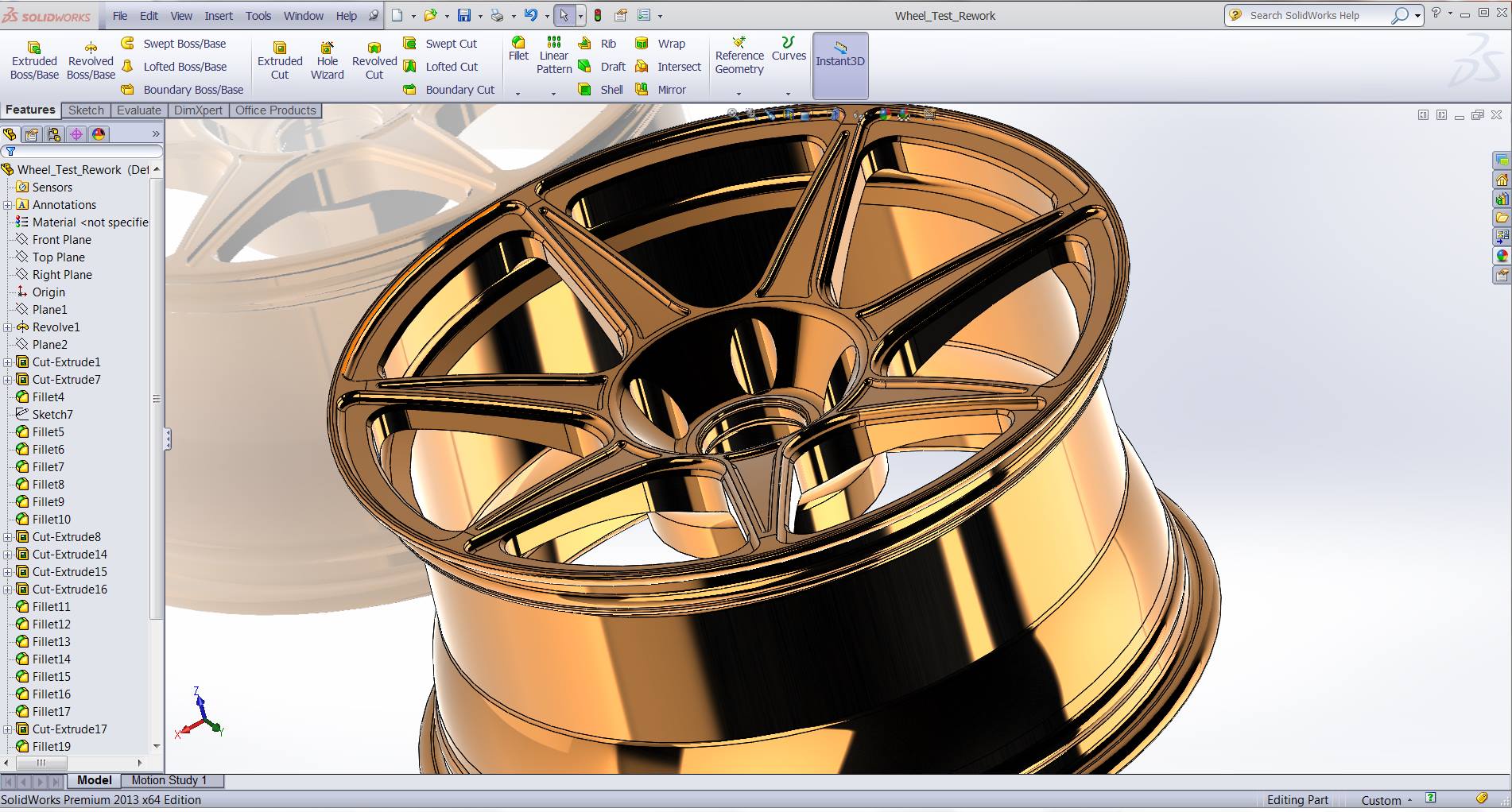

A local shop down the street from my current job specializes in machining 2-piece, 3-piece, and forged monoblocks for private label companies. The owner recently lost his programmer, and a buddy of mine who owns his own wheel brands and uses this shop to make some of his wheels, had thrown my name out there. I went in for a meeting to show what I could do, and we basically started working together that night. I was asked to come up with a super simple design and machine it, so we could kind of work together. He can show me how he runs things, and I can show him I know what I'm doing. So I came up with just a basic design. I started out by modeling up the wheel in Solidworks.

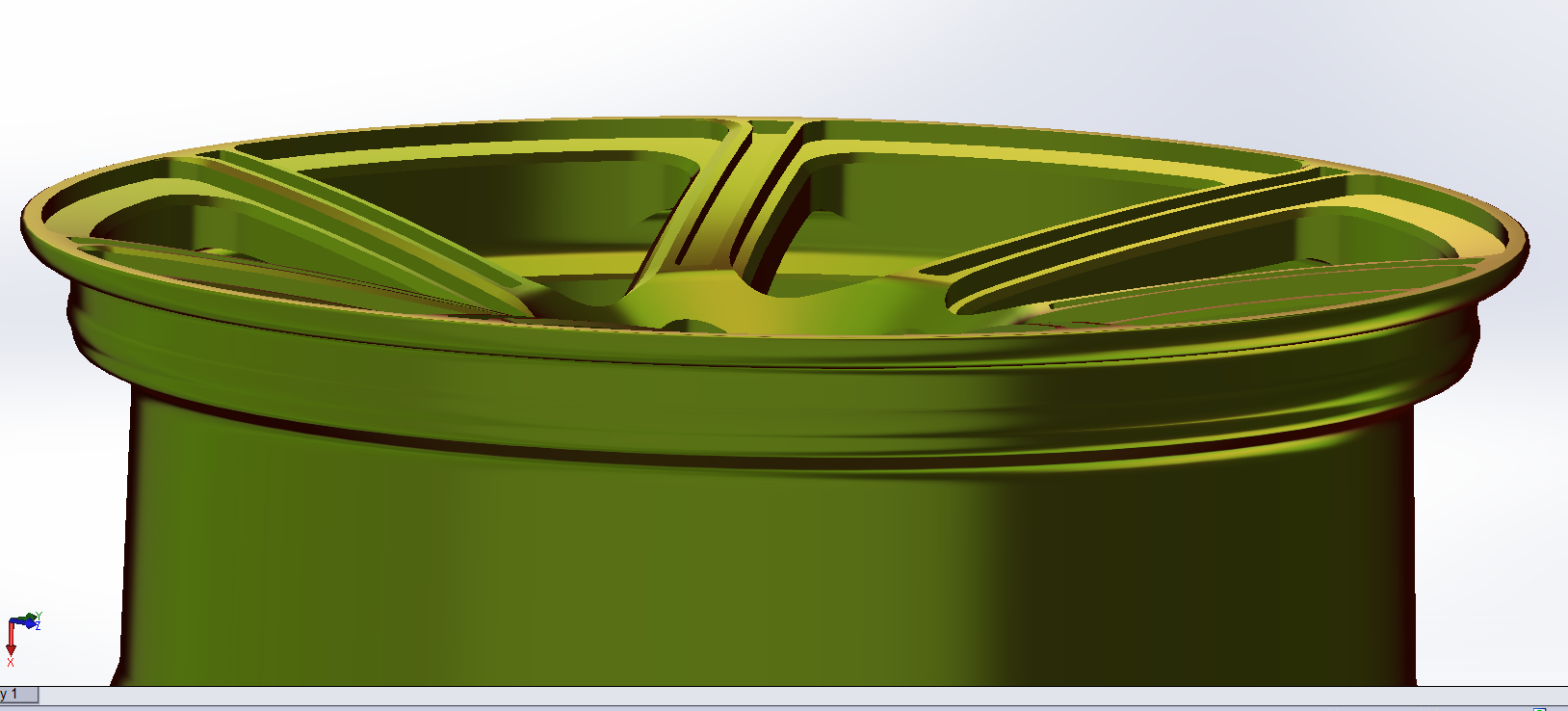

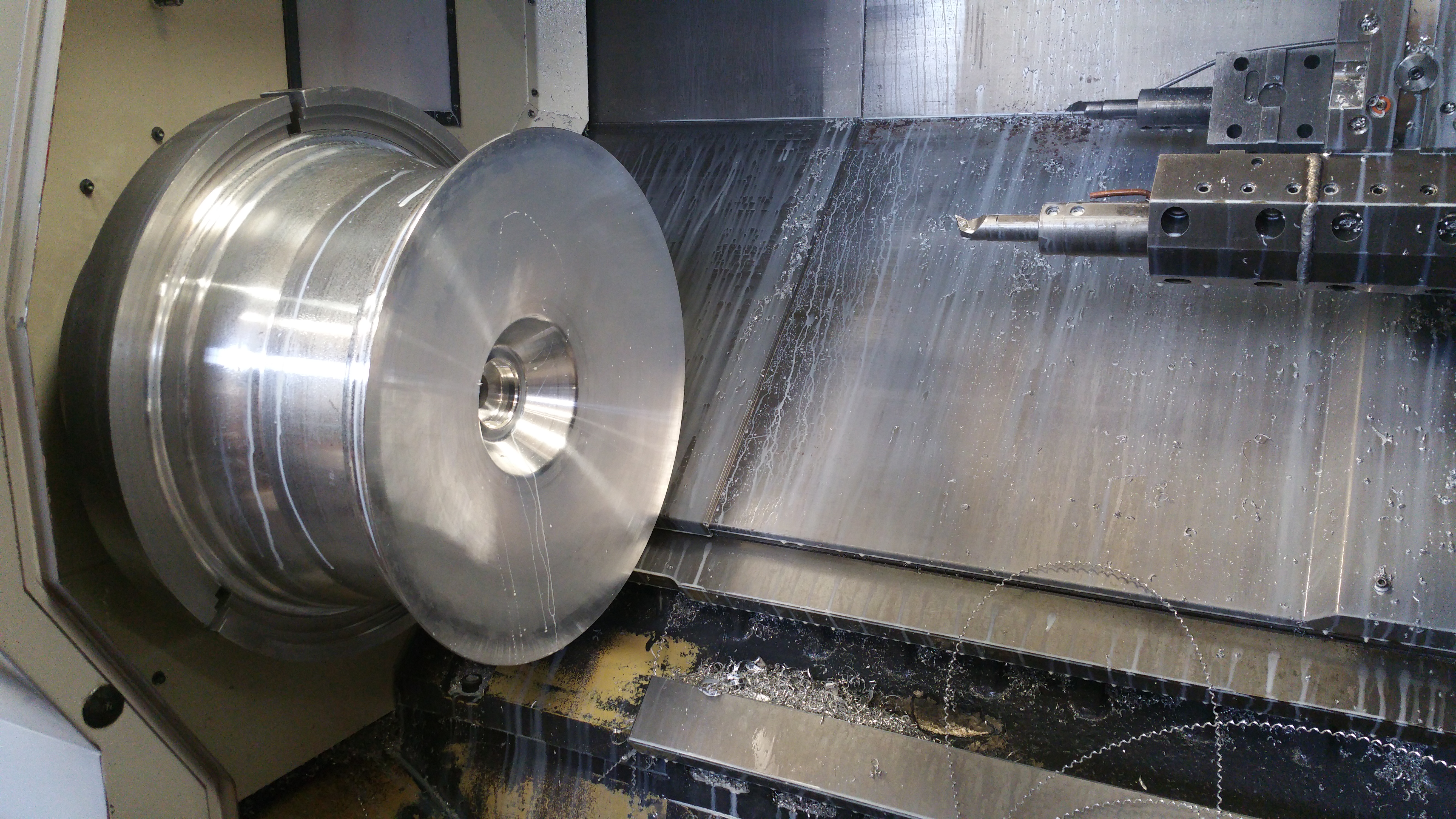

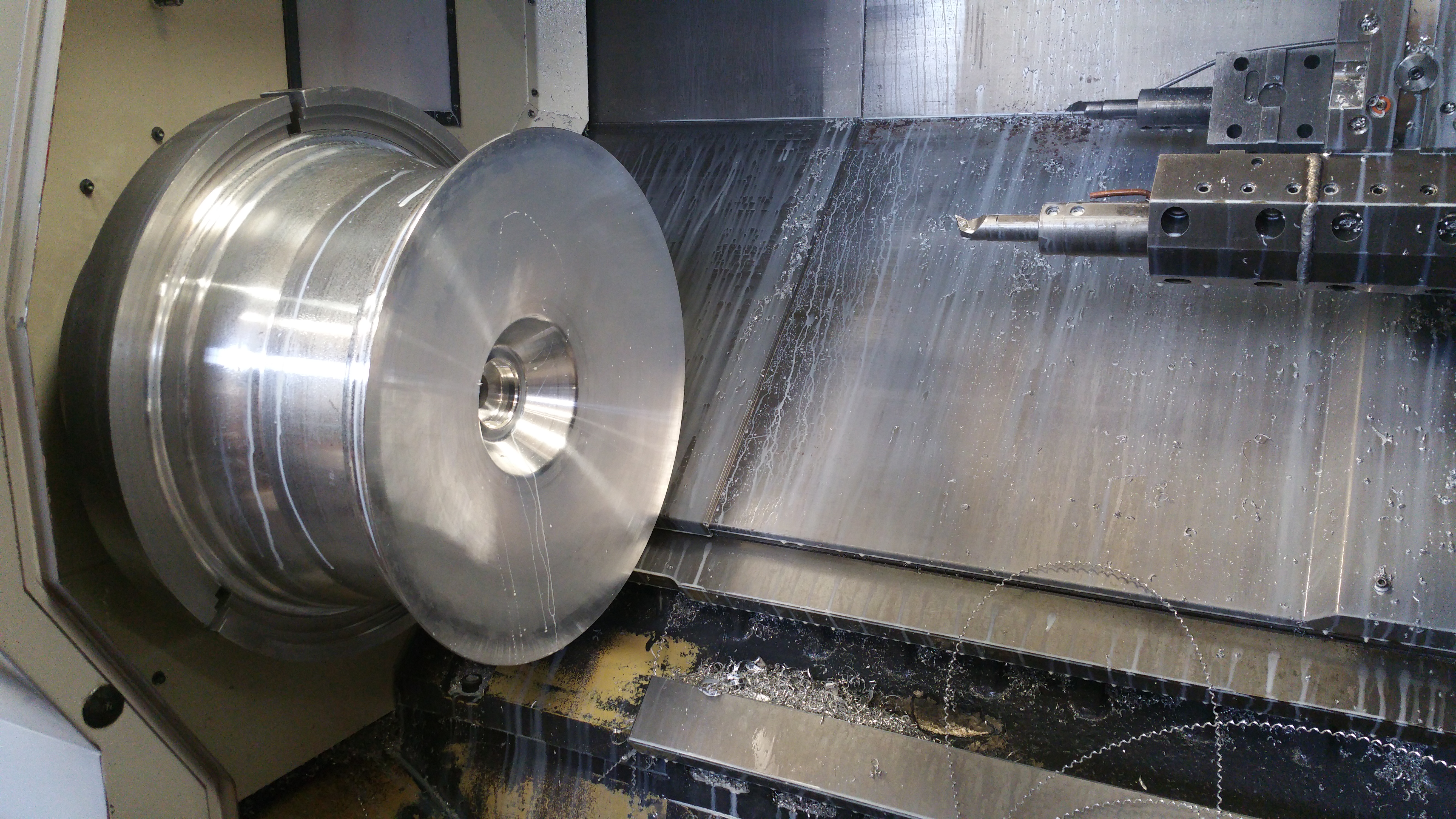

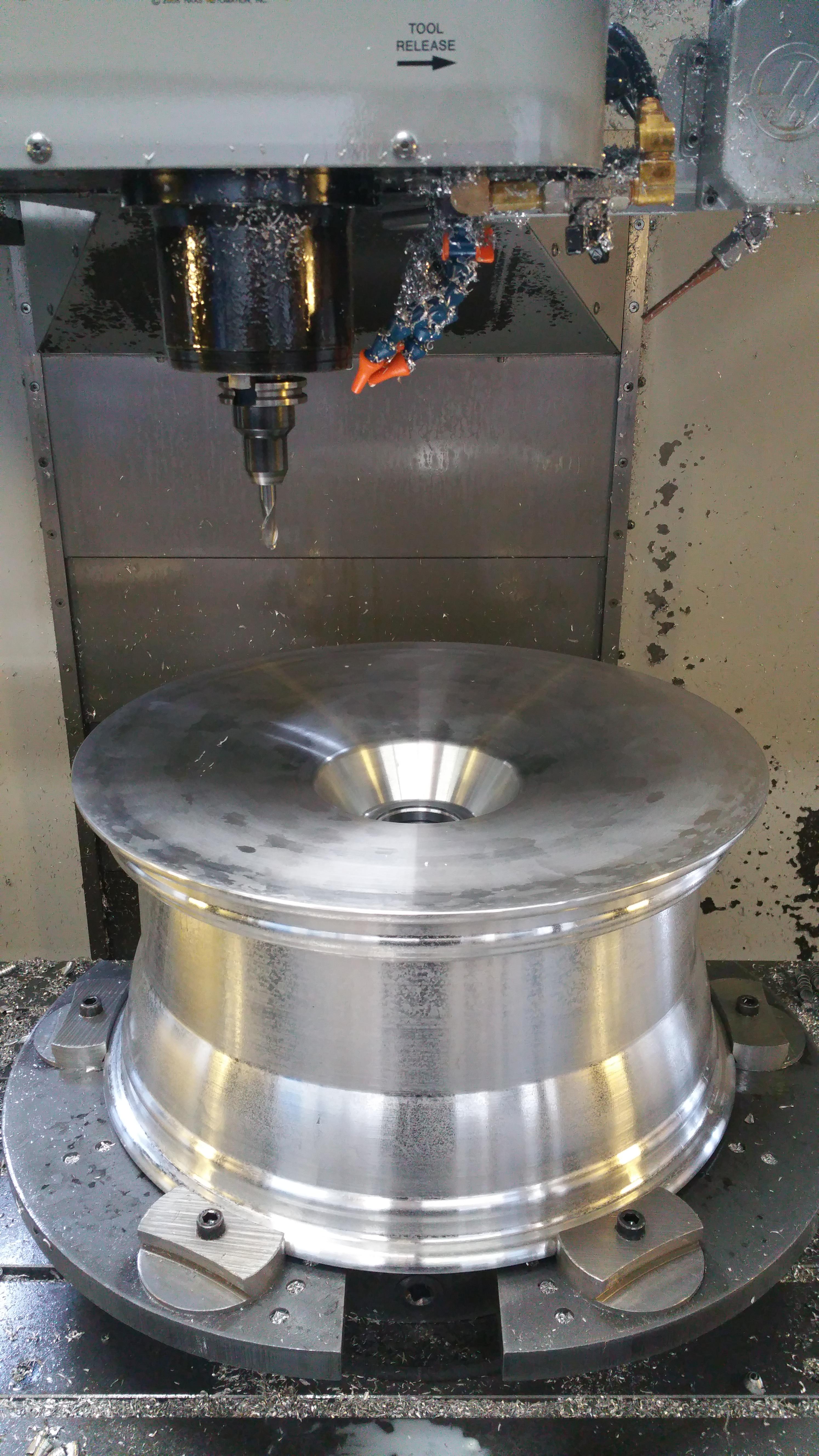

Like I said, just something pretty simple. So we started off by maching the offset, hub diameter, and undercut into the back of a forged monoblock. Once the backside was done, we flipped it around to machine the center cap detail, and then the overall profile of the wheel. This was a preexisting program that we were using on the profile, so its nothing fancy. I only took a couple of pictures since we do things pretty quickly. This is just a picture of the wheel after we machined the profile.

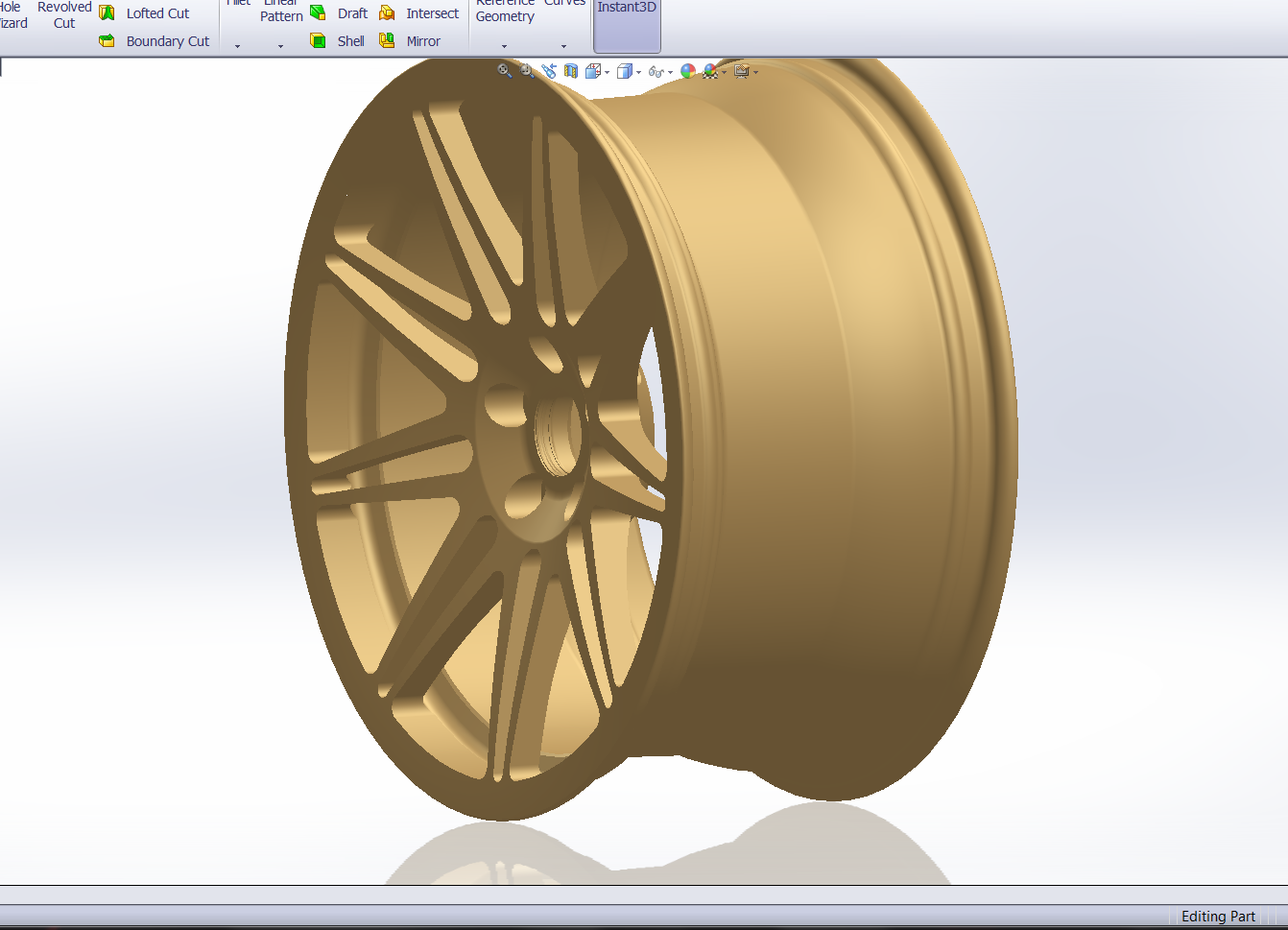

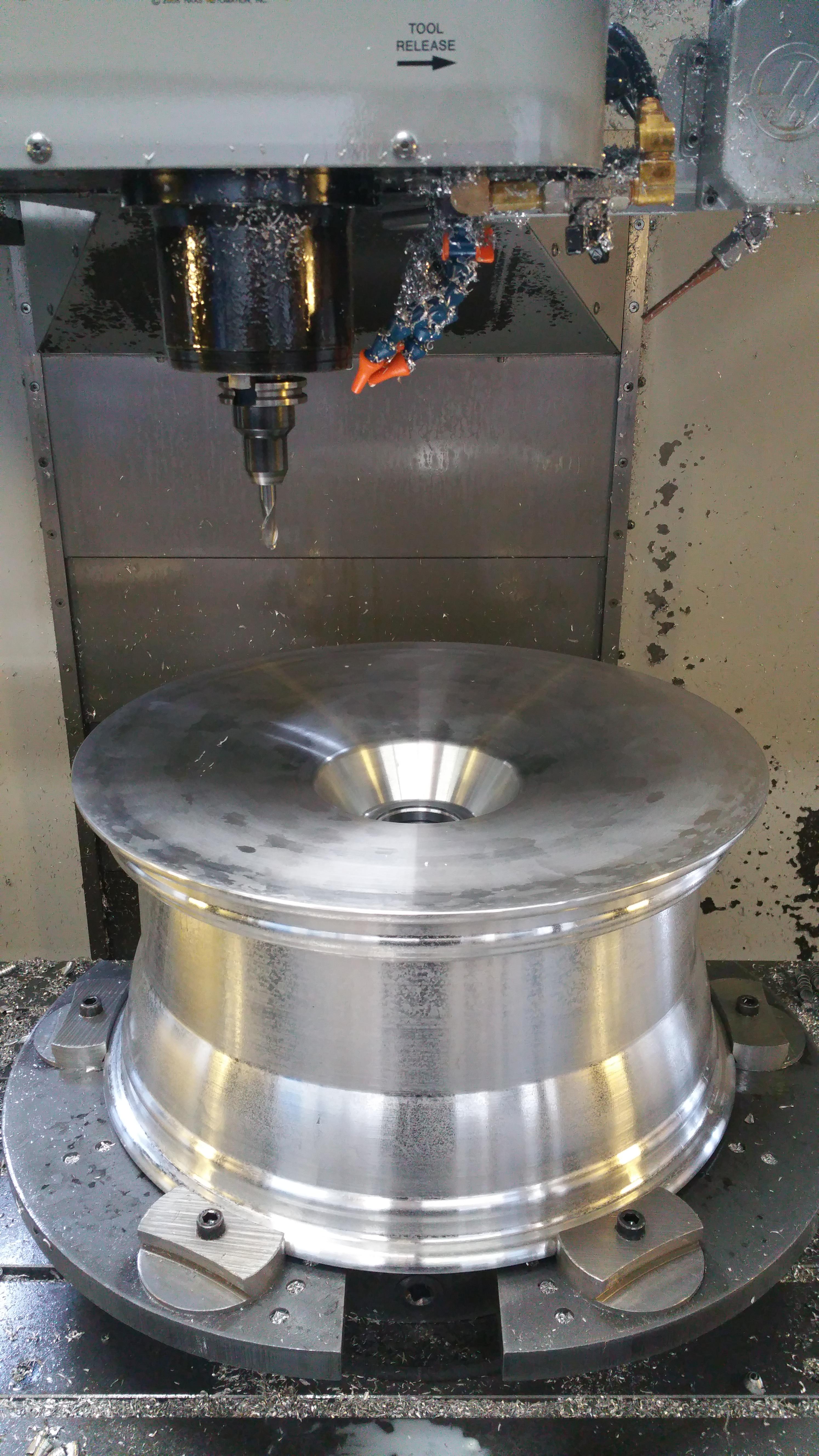

Once the lathe operations were done, it was on to the mill. I machine the design into the wheel, then the bolt pattern was machined. Nothing crazy here, but still came out kind of cool. I really dig blocky looking wheels. We pulled it off the machine and it came out pretty rad. SUPER beefy and you could probably run it into a curb without issue. (Not really.)

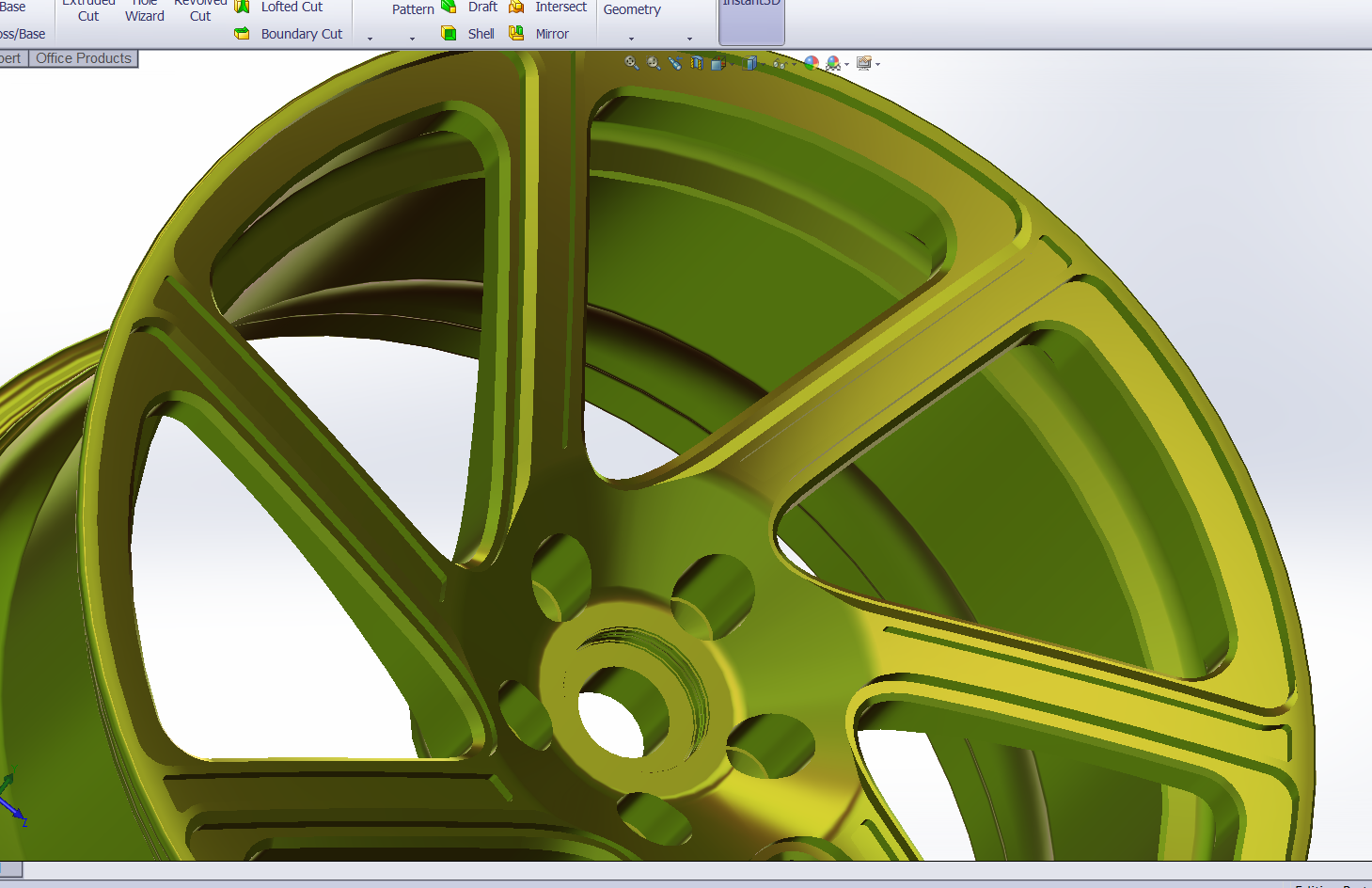

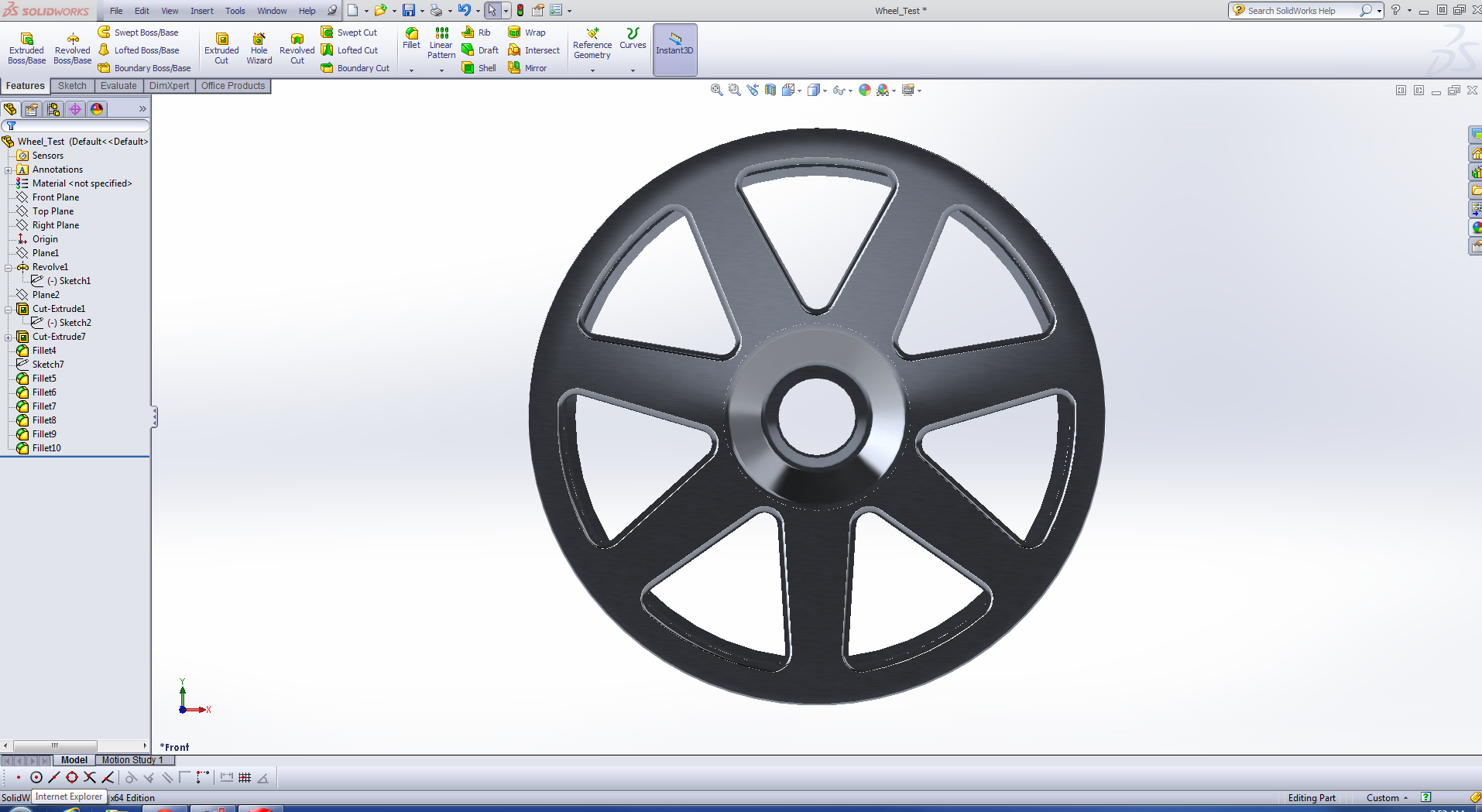

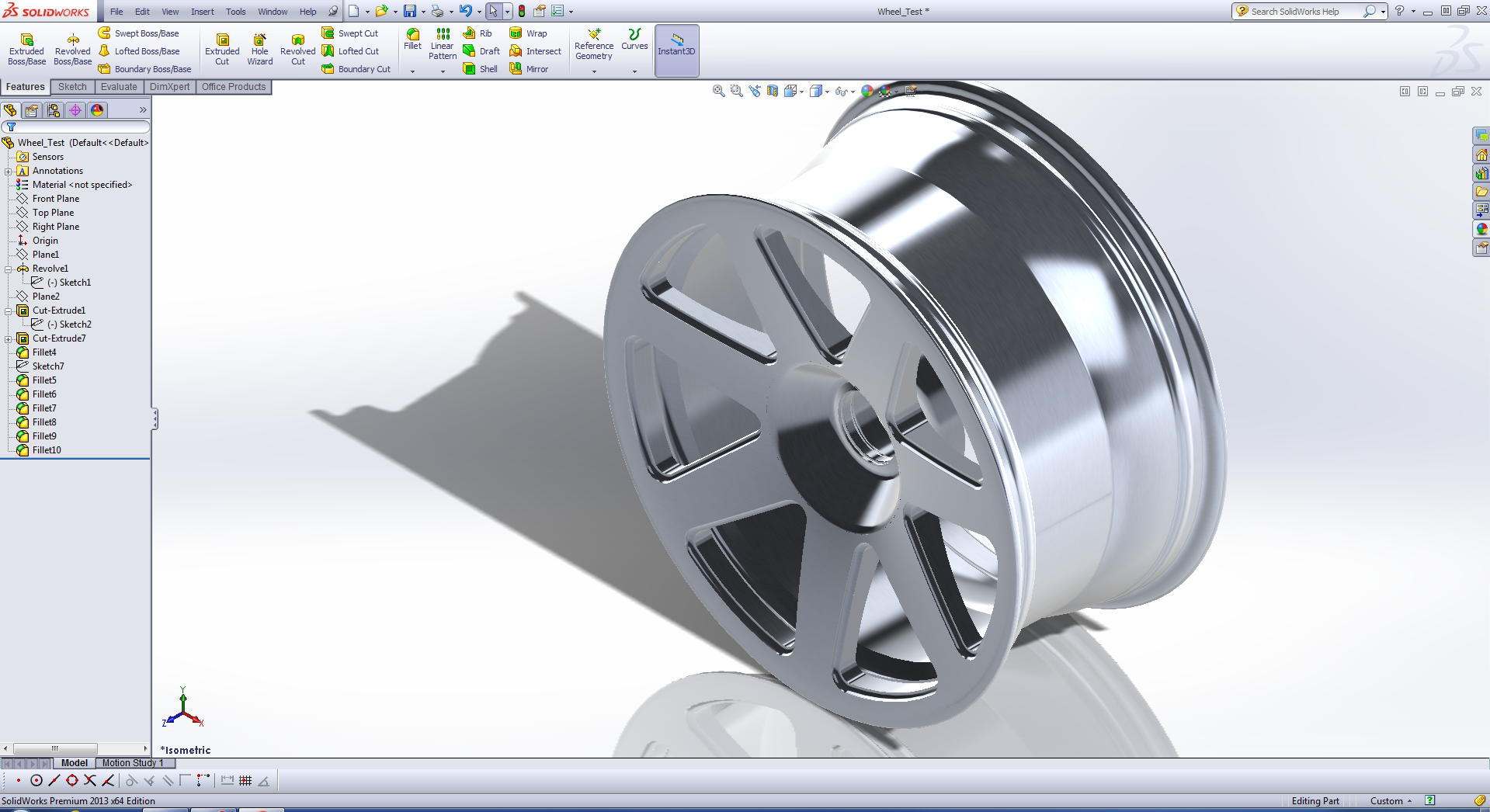

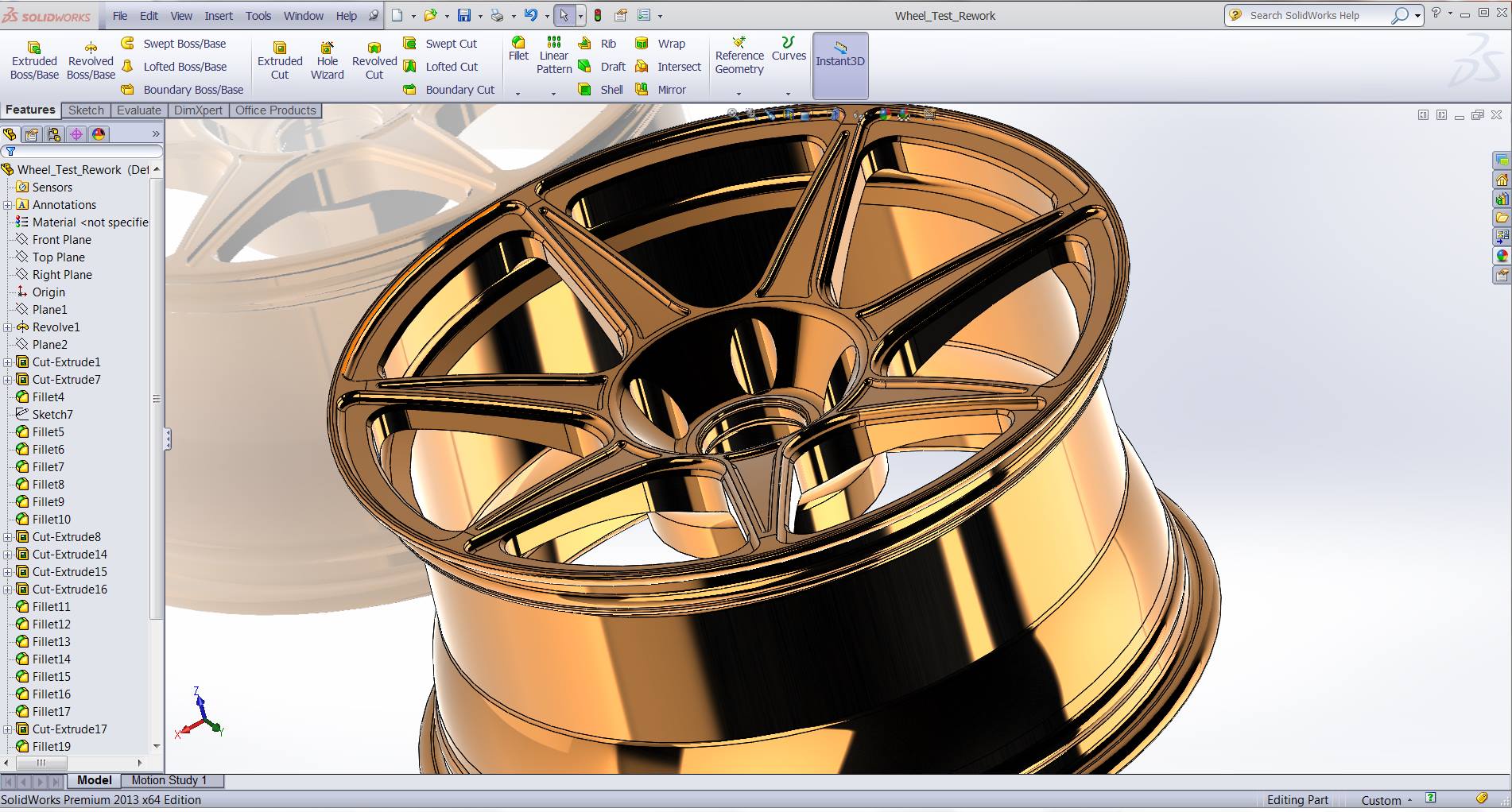

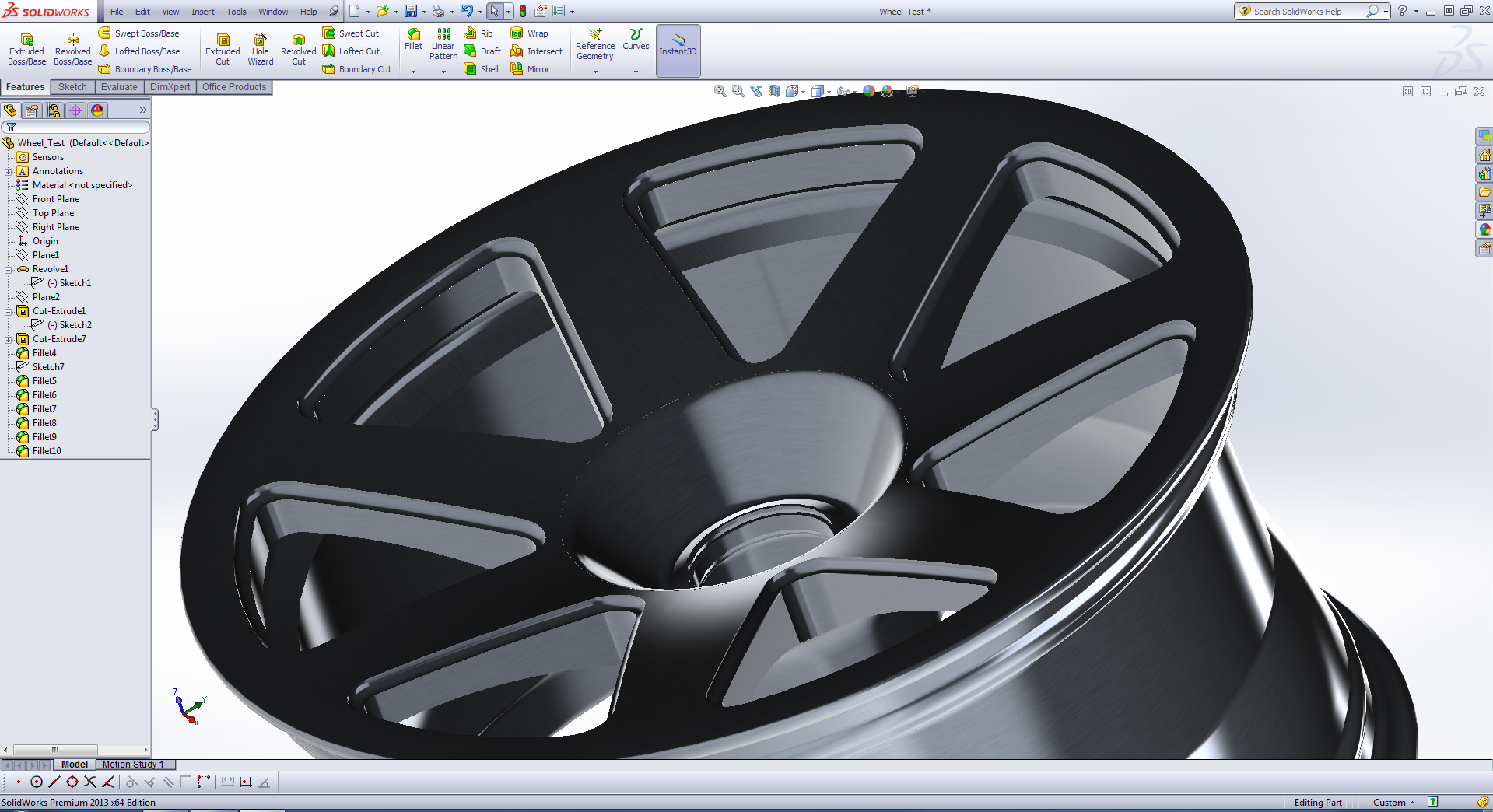

That's when we decided to do something a little more fancy to it. 2 reasons for this; 1 is that this was just a practice wheel and we can do whatever we want to it, and 2 is that this was also a test for me to see what I could come up with. The only challenge this presents is that now I am limited to what I can do. I have to work around the existing cuts. So I came up with something kinda cool. Again, started out by modeling it in Solidworks.

Then it was back to the machine. The only picture I took was when it was off the machine and we were washing it. As you can see, I added quite a few details into the spokes. I think it came out pretty cool.

So after all that, this is where the point of this thread comes in. I am now currently in the process of designing a custom set of wheels for my car. My cost on the forged monoblocks is still pretty pricey, but totally worth it. My plan right now is to run a 20x10 in the front, and a 20x11 in the rear. I am going to custom tailor the offset, as well as come up with a nice design with a little bit of concave in it. Let's be honest, there probably isn't a wheel design that hasn't been done yet, so I'm not going for the most unique wheel that ever existed. I do, however, want to come up with something that will make people who really like wheels know that it was custom made. I'm currently running 20x10 all the way around on my car now, but I figured if I'm going to do it, I might as well do it. haha. I may even end up going 20x12 in the rear. I havent finished drawing up the profile yet, or the design itself, but I am currently working on it. I know a lot of you guys like build threads and seeing how things are done, so I thought this would probably be interesting to a lot of guys out there. So stay tuned, I'll do my best to keep this thread updated constantly.

A local shop down the street from my current job specializes in machining 2-piece, 3-piece, and forged monoblocks for private label companies. The owner recently lost his programmer, and a buddy of mine who owns his own wheel brands and uses this shop to make some of his wheels, had thrown my name out there. I went in for a meeting to show what I could do, and we basically started working together that night. I was asked to come up with a super simple design and machine it, so we could kind of work together. He can show me how he runs things, and I can show him I know what I'm doing. So I came up with just a basic design. I started out by modeling up the wheel in Solidworks.

Like I said, just something pretty simple. So we started off by maching the offset, hub diameter, and undercut into the back of a forged monoblock. Once the backside was done, we flipped it around to machine the center cap detail, and then the overall profile of the wheel. This was a preexisting program that we were using on the profile, so its nothing fancy. I only took a couple of pictures since we do things pretty quickly. This is just a picture of the wheel after we machined the profile.

Once the lathe operations were done, it was on to the mill. I machine the design into the wheel, then the bolt pattern was machined. Nothing crazy here, but still came out kind of cool. I really dig blocky looking wheels. We pulled it off the machine and it came out pretty rad. SUPER beefy and you could probably run it into a curb without issue. (Not really.)

That's when we decided to do something a little more fancy to it. 2 reasons for this; 1 is that this was just a practice wheel and we can do whatever we want to it, and 2 is that this was also a test for me to see what I could come up with. The only challenge this presents is that now I am limited to what I can do. I have to work around the existing cuts. So I came up with something kinda cool. Again, started out by modeling it in Solidworks.

Then it was back to the machine. The only picture I took was when it was off the machine and we were washing it. As you can see, I added quite a few details into the spokes. I think it came out pretty cool.

So after all that, this is where the point of this thread comes in. I am now currently in the process of designing a custom set of wheels for my car. My cost on the forged monoblocks is still pretty pricey, but totally worth it. My plan right now is to run a 20x10 in the front, and a 20x11 in the rear. I am going to custom tailor the offset, as well as come up with a nice design with a little bit of concave in it. Let's be honest, there probably isn't a wheel design that hasn't been done yet, so I'm not going for the most unique wheel that ever existed. I do, however, want to come up with something that will make people who really like wheels know that it was custom made. I'm currently running 20x10 all the way around on my car now, but I figured if I'm going to do it, I might as well do it. haha. I may even end up going 20x12 in the rear. I havent finished drawing up the profile yet, or the design itself, but I am currently working on it. I know a lot of you guys like build threads and seeing how things are done, so I thought this would probably be interesting to a lot of guys out there. So stay tuned, I'll do my best to keep this thread updated constantly.